LiuGong and its partners – Cummins and ZF – chose bauma 2013 to celebrate a string of successes with joint ventures, shared factories, and profitable partnerships. “We looked for only the best partners that share our commitment to excellence,” said Zeng Guang’an, LiuGong’s vice chairman and president. “With Cummins and ZF we believe we have found two of the best.” LiuGong’s joint venture with ZF began in 1995, which allowed the Chinese maker to cost-effectively incorporate high-level ZF technology into its

January 6, 2017

Read time: 2 mins

“We looked for only the best partners that share our commitment to excellence,” said Zeng Guang’an, LiuGong’s vice chairman and president. “With Cummins and ZF we believe we have found two of the best.”

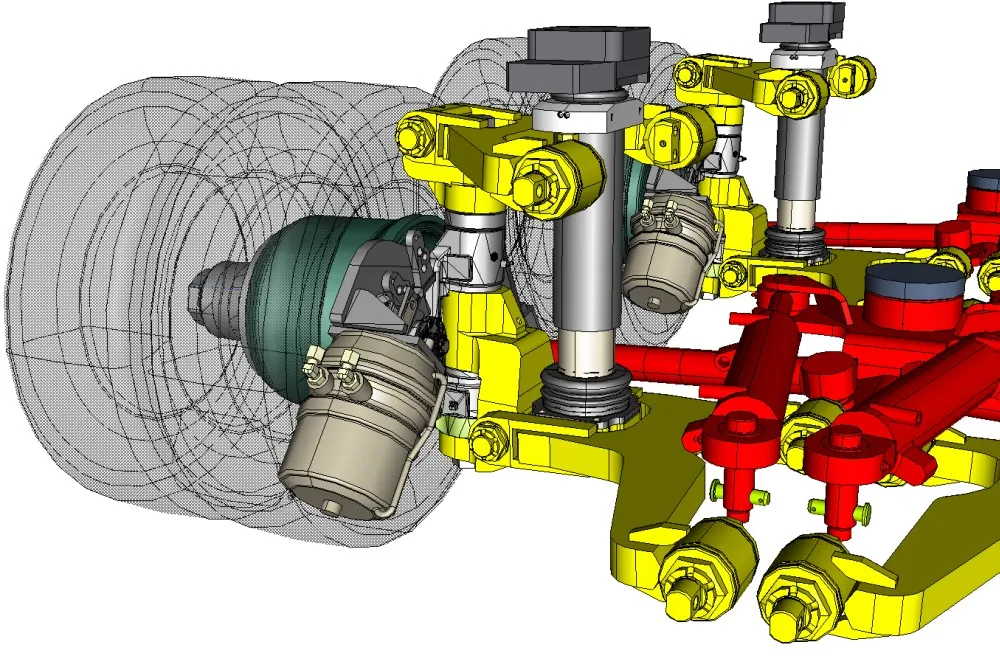

LiuGong’s joint venture with ZF began in 1995, which allowed the Chinese maker to cost-effectively incorporate high-level ZF technology into its products. In 2012, the two partnered again in a second joint venture called ZF Liuzhou Axle Co, to focus on developing and producing construction machinery axles for the Chinese market.

Hermann Beck, ZF vice president industrial technology and head of off-highway systems said, “Along with LiuGong, we have developed the product that exactly matches the requirements for the developing market. The joint efforts will definitely promote the continued growth of both LiuGong and ZF.”

In 2011, LiuGong set up a joint venture company with Cummins called Guangxi Cummins Industrial Power Company (GCIC). The new engine plant, located in Liuzhou City, produced its first Tier II engine – the L9.3 – in March 2013, destined for LuiGong’s wheeled loader range.

“This is a great example of the full strength that comes about when two global companies who are leaders in their fields join together and combine their impressive respective strengths," said Tom Linebarger, chairman and chief executive officer of Cummins. "The value of our partnership can be seen with the introduction of the L9.3, a new engine specifically designed for wheel loader applications.”

Stand: F4.417

%$Linker:

%$Linker: