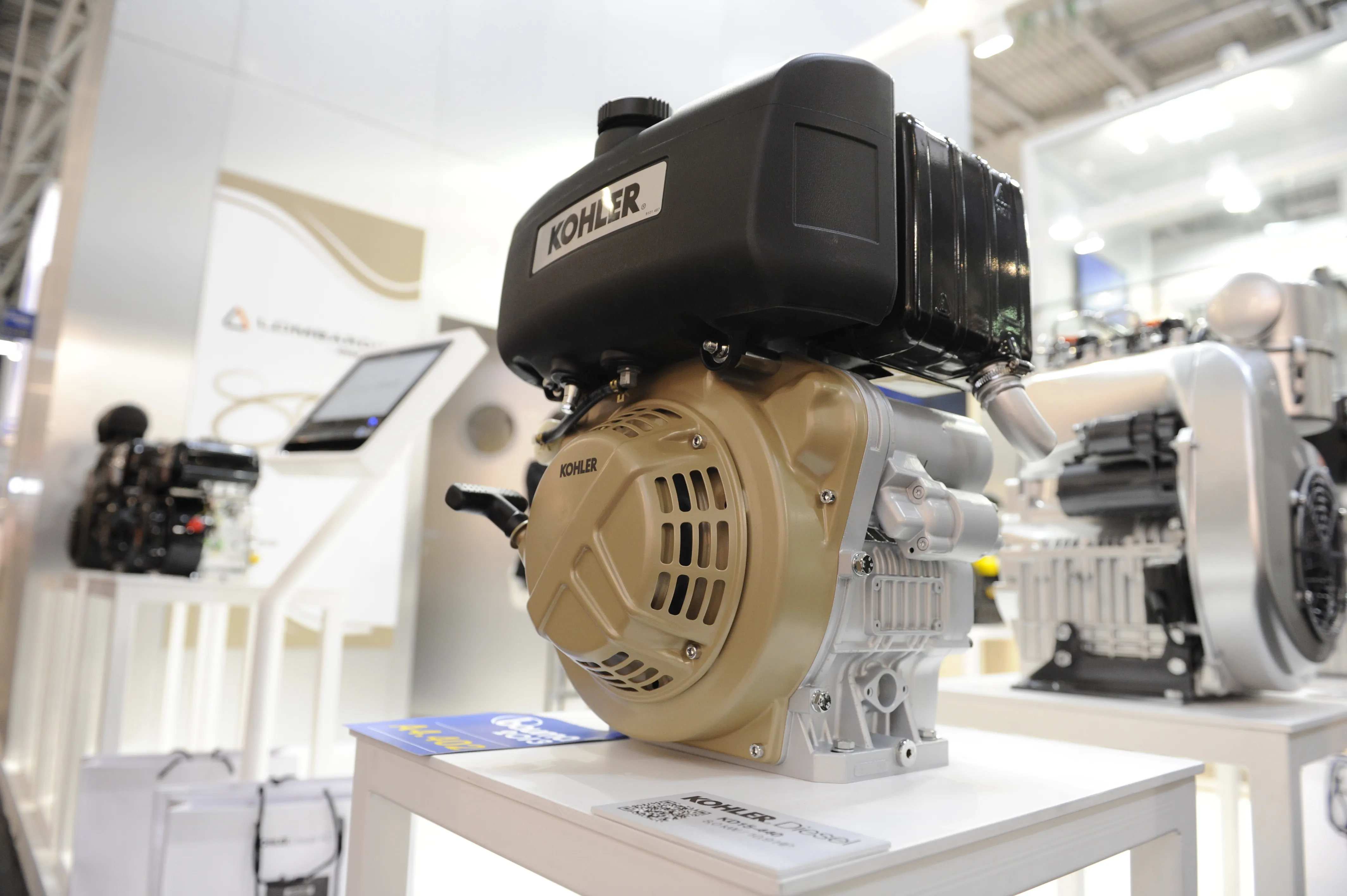

The Kohler/Lombardini group will use Bauma to update its range of air-cooled single cylinder diesel engines, unveiling the new 8kW KD15-440 engine which the manufacturer says will strengthen and improve the current 15LD series - elevating it to the top of the class within its power range. The KD15-440 is an air-cooled single cylinder diesel engine with a displacement of 441cc and an air filter that can offer, Lombardini claims, an operating life five times greater than the current version via its new high-e

January 6, 2017

Read time: 2 mins

The 2278 Kohler/2277 Lombardini group will use Bauma to update its range of air-cooled single cylinder diesel engines, unveiling the new 8kW KD15-440 engine which the manufacturer says will strengthen and improve the current 15LD series - elevating it to the top of the class within its power range. The KD15-440 is an air-cooled single cylinder diesel engine with a displacement of 441cc and an air filter that can offer, Lombardini claims, an operating life five times greater than the current version via its new high-efficiency separator with pre-filter and an accumulated-dust drain valve in the filter itself. There is also a new fuel filter featuring additional pre-filter protection.

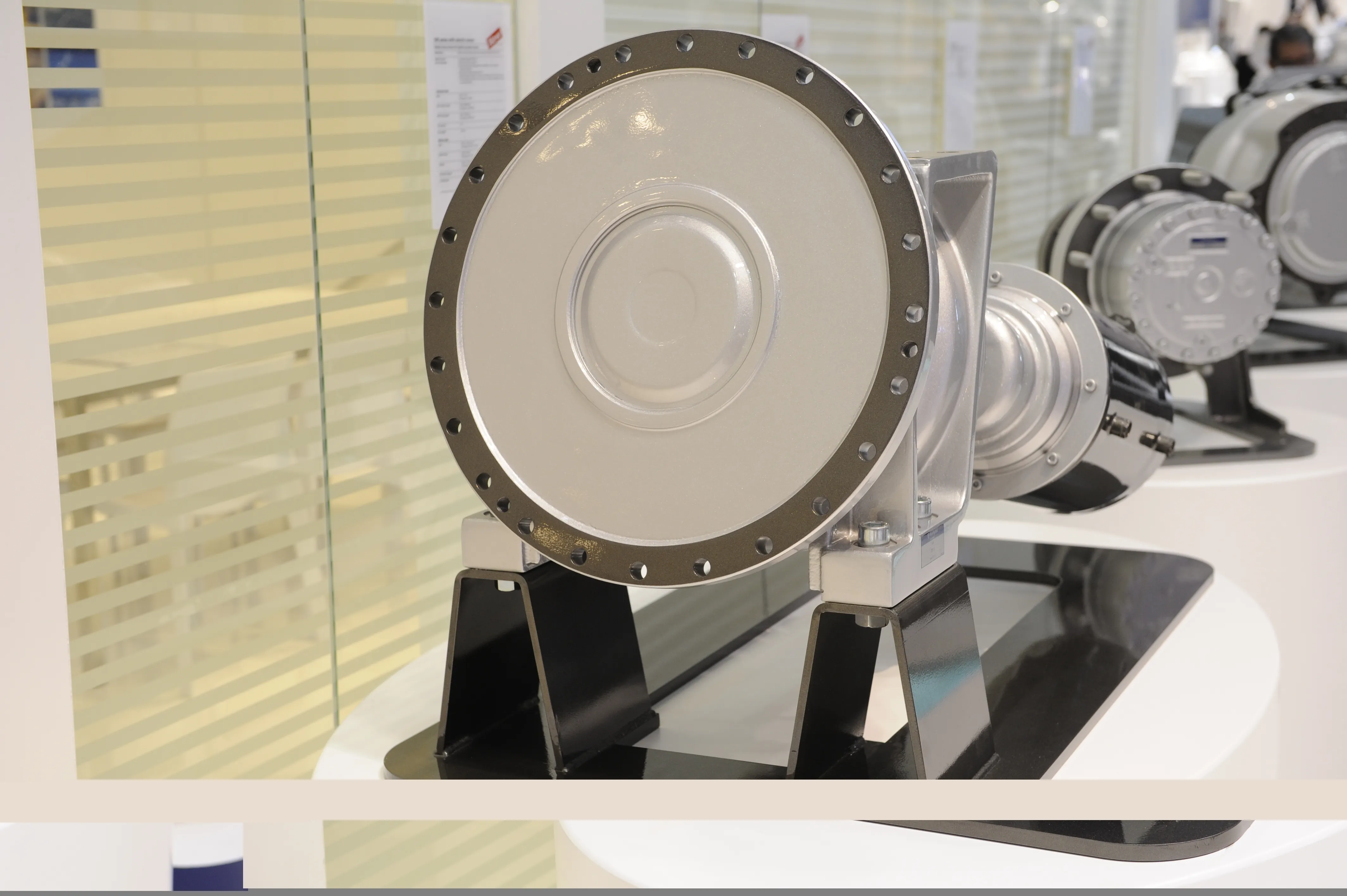

Further up the power chain, Lombardini will also show off a new line of Kohler Direct Injection (KDI) diesel engines, all of which have been prepared to meet the demands of the latest emissions regulations. This new and updated KDI series achieves clean diesel fuel combustion by using a high-pressure (2000 bar) common rail system of the latest generation, combined with an electronically triggered EGR valve that makes circulate the right amount of exhaust gases (which are liquid-cooled by a water/air heat exchanger). This, Lombardini claims, enables emission levels to comply with the new regulations while providing exceptional performance - and all without the use of after-treatment systems. There are three direct injection families, each with a different displacement rated at 1.9litres, 2.5litres, and 3.4litres, and each one is available in two different configurations: Mechanical injection to comply with Tier 3/Stage IIIA emission requirements; or common rail injection to comply with Tier 4/Stage IIIB emission requirements. The 1.9litre and the 2.5litre engines are already in production and a prototype 3.4litre unit will be on show at Bauma.

2 Internal <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 11560 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/bauma-2013/video/ true false %>

Further up the power chain, Lombardini will also show off a new line of Kohler Direct Injection (KDI) diesel engines, all of which have been prepared to meet the demands of the latest emissions regulations. This new and updated KDI series achieves clean diesel fuel combustion by using a high-pressure (2000 bar) common rail system of the latest generation, combined with an electronically triggered EGR valve that makes circulate the right amount of exhaust gases (which are liquid-cooled by a water/air heat exchanger). This, Lombardini claims, enables emission levels to comply with the new regulations while providing exceptional performance - and all without the use of after-treatment systems. There are three direct injection families, each with a different displacement rated at 1.9litres, 2.5litres, and 3.4litres, and each one is available in two different configurations: Mechanical injection to comply with Tier 3/Stage IIIA emission requirements; or common rail injection to comply with Tier 4/Stage IIIB emission requirements. The 1.9litre and the 2.5litre engines are already in production and a prototype 3.4litre unit will be on show at Bauma.

Stand: A4-402

%$Linker: