LiuGong Machinery Corporation is showing its line of dozers at INTERMAT. The three dozers are manufactured in the company’s newly-acquired plant in Poland following the recent acquisition of HSW (Huta Stalowa Wola) Dressta, a company noted for bulldozer technology. This is the first time the dozers are being presented as part of LiuGong and they include the TD-14M with an operating weight of 15,550kg and a blade capacity of 4.28m³; the TD-20M (operating weight 23,650kg and a blade capacity of 8.45 m³) and t

April 18, 2012

Read time: 2 mins

The three dozers are manufactured in the company’s newly-acquired plant in Poland following the recent acquisition of HSW (

This is the first time the dozers are being presented as part of LiuGong and they include the TD-14M with an operating weight of 15,550kg and a blade capacity of 4.28m³; the TD-20M (operating weight 23,650kg and a blade capacity of 8.45 m³) and the TD-40E, which has an operating weight of 67,700kg and a blade capacity of 39.8m³.

The LiuGong Dressta bulldozer has powerful

The advanced electro-hydraulic steering system features pre-set travel speed selection and automatic downshift while all three machines feature sound-suppressed cabins with pressurised air-conditioning and heat and a fully adjustable, pivoting air-suspension seat.

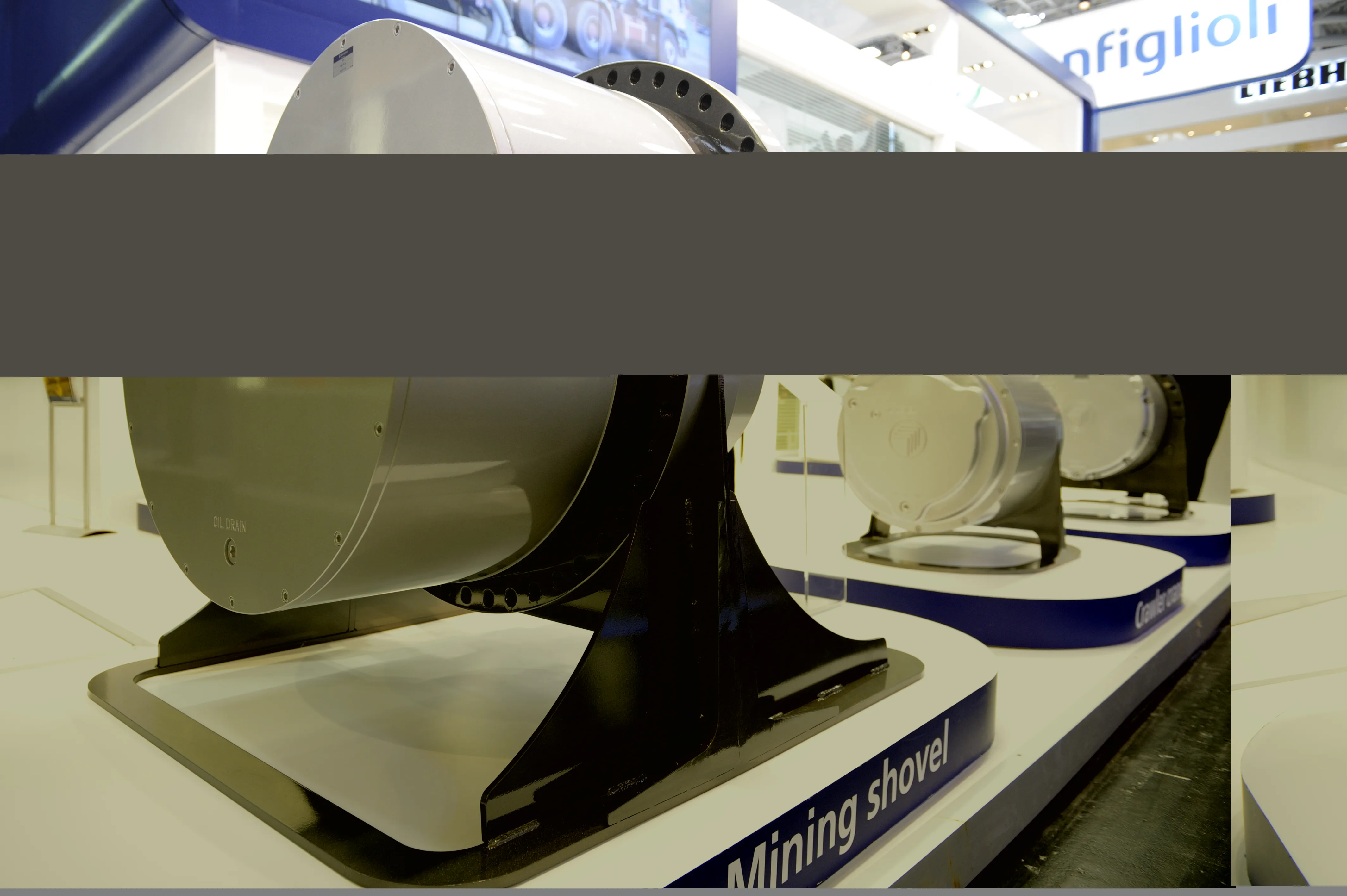

“The exclusive single-rail modular powertrain provides ready access to all its components: engine, torque converter, transmission, steering drive and final drives. Because the system is modular, each part can be serviced separately in the field,” said LiuGong.

%$Linker: