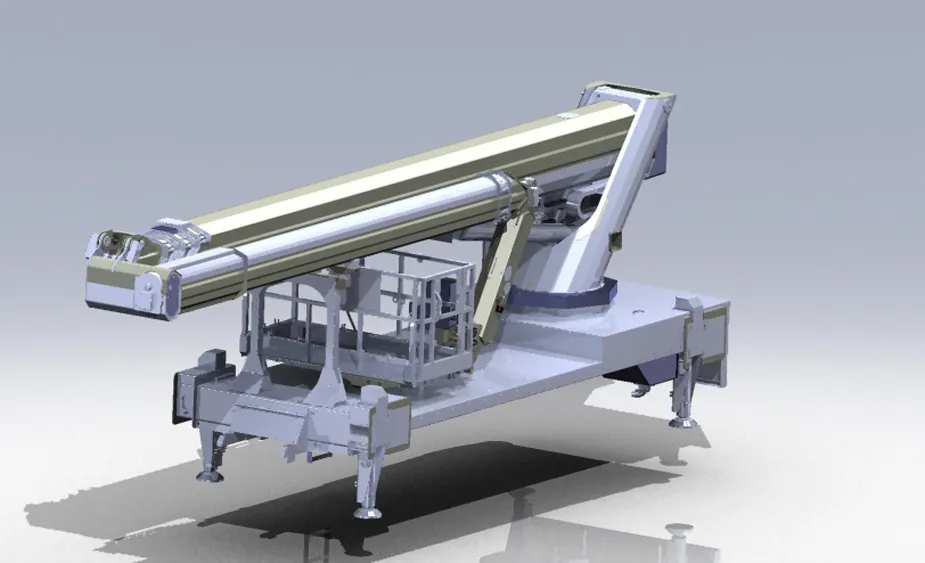

German company Lintec will present for the first time its specially designed and fully containerised Gussasphalt plant for the European Market, the CDD 1200 GA. The plant has a capacity of 20tonnes of Gussasphalt per hour (optional up to 20tonnes/hour), and was sold to the French company SMAC (belonging to the Colas Group) and will operate in the west of France near Rennes.

The plant has a hot bin with one chamber and can take 15tonnes of material while the recuperated filler silo is 11tonnes and one or tw

April 12, 2012

Read time: 2 mins

%$Linker: 2 Internal 2 4802 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">RSS</span></span> Road Paving and Recycling false /event-news/intermat-2012/rss/road-paving-and-recycling/ true false %>German company 1177 Lintec is presenting for the first time its specially designed and fully containerised Gussasphalt plant for the European Market, the CDD 1200 GA.

The plant has a capacity of 20tonnes of Gussasphalt per hour (optional up to 20tonnes/hour), and was sold to the French company SMAC (belonging to the184 Colas Group) and will operate in the west of France near Rennes.

The plant has a hot bin with one chamber and can take 15tonnes of material while the recuperated filler silo is 11tonnes and one or two Gussasphalt silos on load cells are each 6tonnes.

Other components include a quick mixer (1,000kg); integrated bucket (1,000kg); aggregate weigher (800kg) and filler weigher with four inlets (200kg).

“Apart from this special solution Lintec is well-known for fully containerised asphalt and concrete mixing plants. The Lintec product range covers asphalt mixing plants with a capacity from 80-400tonnes and concrete mixing plants with a capacity from 60-240m³/hour,” says Lintec.

The presented Gussasphalt Plant was developed together with Lintec’s partner company Linnhoff & Henne, which will co-exhibit with Lintec and present machinery related to Gussasphalt.

2 Internal 2 4824 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/intermat-2012/video/ true false %>

The plant has a capacity of 20tonnes of Gussasphalt per hour (optional up to 20tonnes/hour), and was sold to the French company SMAC (belonging to the

The plant has a hot bin with one chamber and can take 15tonnes of material while the recuperated filler silo is 11tonnes and one or two Gussasphalt silos on load cells are each 6tonnes.

Other components include a quick mixer (1,000kg); integrated bucket (1,000kg); aggregate weigher (800kg) and filler weigher with four inlets (200kg).

“Apart from this special solution Lintec is well-known for fully containerised asphalt and concrete mixing plants. The Lintec product range covers asphalt mixing plants with a capacity from 80-400tonnes and concrete mixing plants with a capacity from 60-240m³/hour,” says Lintec.

The presented Gussasphalt Plant was developed together with Lintec’s partner company Linnhoff & Henne, which will co-exhibit with Lintec and present machinery related to Gussasphalt.

%$Linker:

Outside: E2 Stand: C036

%$Linker: