Wear parts specialist ESCO is using Bauma to show its new Nemisys lip system which has been engineered to deliver a lighter weight lip better sized and suited to modern buckets. The lip’s streamlined profile optimises production, says ESCO, and machine working cycles. A clever new hammerless tooth and shroud system helps reduce maintenance costs through improved reliability, faster and safer replacement, and improved lip coverage. The slim lip design and matching tooth system require 10% less force to penet

February 15, 2013

Read time: 2 mins

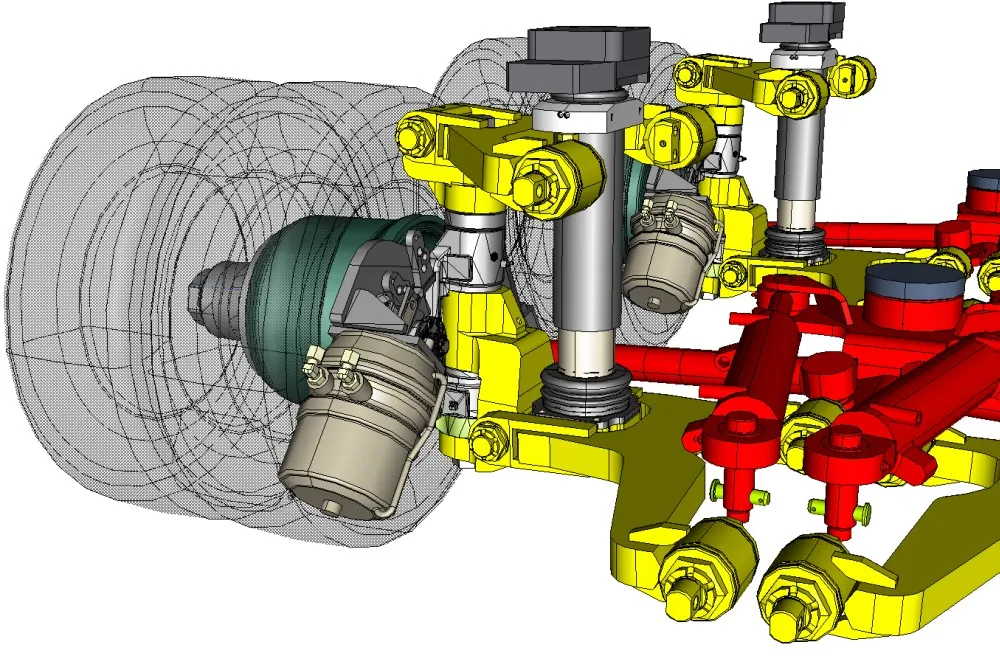

Wear parts specialist 7160 ESCO is using 688 Bauma to show its new Nemisys lip system which has been engineered to deliver a lighter weight lip better sized and suited to modern buckets. The lip’s streamlined profile optimises production, says ESCO, and machine working cycles. A clever new hammerless tooth and shroud system helps reduce maintenance costs through improved reliability, faster and safer replacement, and improved lip coverage. The slim lip design and matching tooth system require 10% less force to penetrate on average and the teeth used offer up to 19% more useable wear metal for more uptime. Nemisys lips weigh 7% less on average than their predecessors says ESCO, which enables additional carrying capacity.

The new system also features hammerless locking via cast-in lifting eyes to simplify handling. There are intermediate adapters featuring dual locking mechanisms for less movement and the teeth are better able to maintain strength throughout the wear cycle. Also, maintenance costs should fall with the Nemisys lip system because ESCO has built in greater time between major lip rebuilds due to an average of 12% reduction in peak stresses in the lip. The shrouds direct material flow away from adapter horns for longer maintenance cycles and the adapters and points use the same locking device and do not require special removal tools. This will be the first time ESCO has exhibited the full Nemisys product range.

ESCO will also have its slim profile and smooth point-to-adapter transition design Ultralok tooth system on show at Bauma. Unlike other products, the Ultralok lock is hammerless and integrated with the point – making the system two pieces, not three. Field replacement is therefore safer, simpler and easier, says ESCO. The manufacturer will be discussing how this 2-piece tooth system is about to be fitted to a ripping and quarrying clamshell bucket for the first time and outlining its plans to re-enter the crushing market in North America.

2 Internal <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 11560 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/bauma-2013/video/ true false %>

The new system also features hammerless locking via cast-in lifting eyes to simplify handling. There are intermediate adapters featuring dual locking mechanisms for less movement and the teeth are better able to maintain strength throughout the wear cycle. Also, maintenance costs should fall with the Nemisys lip system because ESCO has built in greater time between major lip rebuilds due to an average of 12% reduction in peak stresses in the lip. The shrouds direct material flow away from adapter horns for longer maintenance cycles and the adapters and points use the same locking device and do not require special removal tools. This will be the first time ESCO has exhibited the full Nemisys product range.

ESCO will also have its slim profile and smooth point-to-adapter transition design Ultralok tooth system on show at Bauma. Unlike other products, the Ultralok lock is hammerless and integrated with the point – making the system two pieces, not three. Field replacement is therefore safer, simpler and easier, says ESCO. The manufacturer will be discussing how this 2-piece tooth system is about to be fitted to a ripping and quarrying clamshell bucket for the first time and outlining its plans to re-enter the crushing market in North America.

%$Linker: