Liebherr will be showcasing at INTERMAT 2012 its auxiliary power unit (APU) powering the air conditioning on its LR series lift cranes. The Switzerland-based firm says the APU allows the crane operator to turn off the engine and still stay cool – saving its owner money on fuel, service costs and residual value.

January 6, 2017

Read time: 2 mins

The Switzerland-based firm says the APU allows the crane operator to turn off the engine and still stay cool – saving its owner money on fuel, service costs and residual value.

It takes 16 litres of fuel per hour to run an average crawler crane engine on idle, according to Liebherr, and the APU is said to dramatically reduce that fuel requirement and associated expense. Liebherr says 16,000 litres a year can be saved if, as a conservative estimate, a crane is run idle 50% of the time.

With operating hours halved, Liebherr says service intervals are lengthened and the amount of maintenance required can also be reduced by up to 50%.

Further financial benefits can also be realised, says the firm, when it comes time to sell the crane as it will have fewer operating hours on the clock.

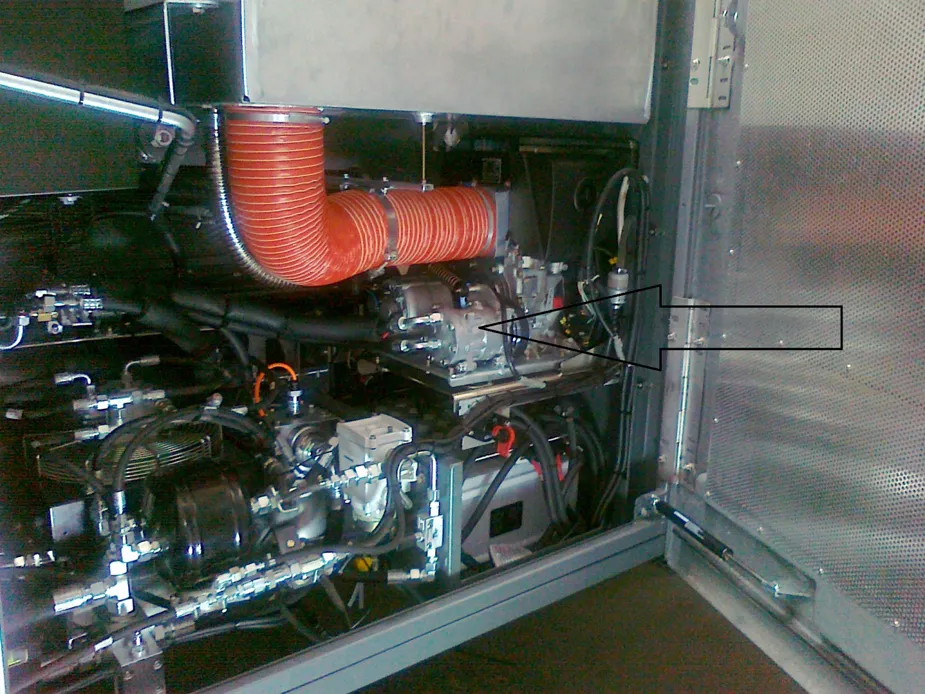

Liebherr crawler cranes use 270kW or 450kW (362hp/600hp) diesel engines, depending on model. The APU is a small 11kW (15hp) Hatz diesel motor – more than ample to power the air conditioning. The APU is integrated into the machinery house, designed into the machine, and secure from the possibility of damage.

%$Linker: