Liebherr has started building a new components development and manufacturing plant in Biberach an der Riss (Baden-Württemberg) in southern Germany.

The development and manufacture of switchgear and also electric motors and generators, currently functions of the company's existing factory in Biberach, are to be relocated to the new site. With the new plant, Liebherr-Components Biberach will have the additional capacity necessary to meet the growing demand of these products in the long term.

August 29, 2013

Read time: 2 mins

The development and manufacture of switchgear and also electric motors and generators, currently functions of the company's existing factory in Biberach, are to be relocated to the new site. With the new plant, Liebherr-Components Biberach will have the additional capacity necessary to meet the growing demand of these products in the long term.

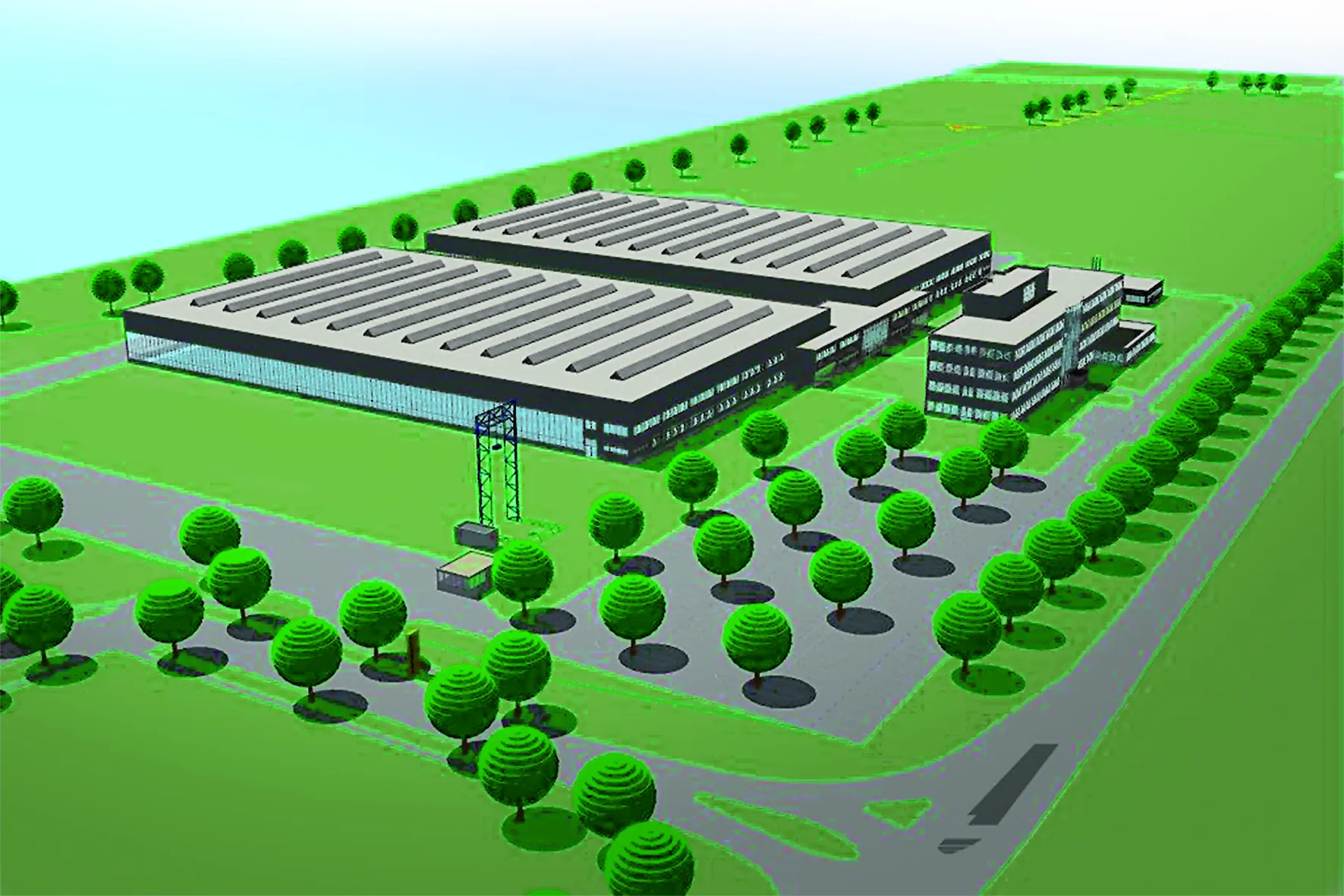

Measuring 14.5ha, the site in Biberach an der Riss will initially have two production halls built on it, each with a surface area of over 10,000m². Another building that combines the two halls will offer a floor space of about 4,500m² for a showroom and communal facilities, among other things. An office building with four floors and a usable area of over 7,200m² will be built on the new site. Additionally, there are plans for a combined heat and power plant to cover the basic energy requirements for the production halls. Capacities to extend the factory have already been taken account of in the site and building plans.

The new €50 million plant is scheduled to commence production by the end of 2014. For the development and manufacture of switchgear as well as electric motors and generators, Liebherr-Components Biberach currently employs around 150 people who will move to the new site. The number of employees working at Liebherr-Components Biberach is likely to increase in the long-term.