Leica Geosystems has unveiled its new powerful Leica iCON 3D machine control system for wheeled loaders. The Swiss firm says the system allows users to complete their earthworks jobs faster and correctly the first time. It is also said to precisely control material cut and fill, saving a lot of time and money by reducing rework and over-excavation, while also making grading operations with wheeled loaders more efficient. Grade checking, says Leica, can be eliminated, further enhancing productivity, efficien

January 6, 2017

Read time: 2 mins

The Swiss firm says the system allows users to complete their earthworks jobs faster and correctly the first time. It is also said to precisely control material cut and fill, saving a lot of time and money by reducing rework and over-excavation, while also making grading operations with wheeled loaders more efficient. Grade checking, says Leica, can be eliminated, further enhancing productivity, efficiency and safety onsite.

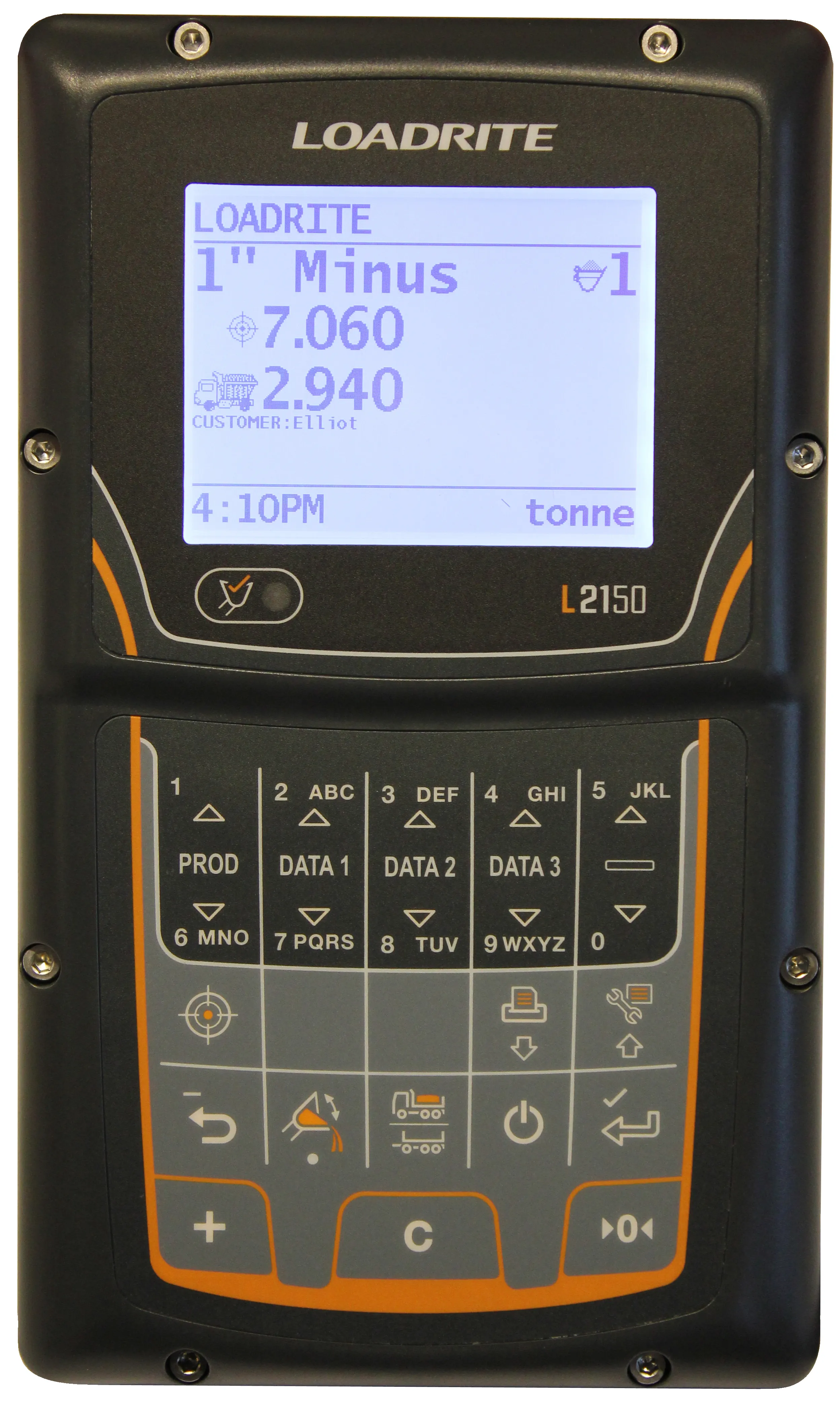

Design information and real-time cut and fill indications are displayed on the control panel in the cab. The operator-friendly user interface with graphical colour display is said to provide full guidance and allows easy operation.

The iCON machine control for wheeled loaders uses modern GNSS technology. The dual GPS solution provides the user real-time position of the bucket allowing for the operator to apply instantaneous adjustments to the bucket position.

An innovative, patented PowerSnap functionality is said to allow fast exchange of control panels between machines.

Leica iCON also supports Leica iCON telematics, which enables users easy data transfer from office to machines, remote support and basic fleet management via the iCONnect website.

Stand: A3.125/226

%$Linker: