A Russian construction company recently visited the Kolberg-Pioneer, (KPI-JCI) factory in Yankton, South Dakota, USA, to review its purchase of KPI-JCI material handling equipment that has never before been used in the country. Nikolai Skripal and his wife, Svetlana, owners of Gazpromdorstroy Construction Company in Orenburg, Russia, visited the manufacturing facility to approve the shipment of its new KPI-JCI 52S Pugmill system and conveyor. The 52S Pugmill system is the first of its kind shipped from KPI

April 23, 2013

Read time: 2 mins

A Russian construction company recently visited the Kolberg-Pioneer, (3363 KPI-JCI) factory in Yankton, South Dakota, USA, to review its purchase of KPI-JCI material handling equipment that has never before been used in the country.

Nikolai Skripal and his wife, Svetlana, owners of Gazpromdorstroy Construction Company in Orenburg, Russia, visited the manufacturing facility to approve the shipment of its new KPI-JCI 52S Pugmill system and conveyor. The 52S Pugmill system is the first of its kind shipped from KPI to Russia, said Bruce Viau, international sales coordinator for Kolberg-Pioneer.

“The system that Gazpromdorstroy Construction Company has purchased will be used to build farm-to-market roads in the interior of Russia,” Viau said.

“Orenburg is located in the southern Ural Mountains near the border with Kazakhstan. The farm-to-market roads are similar to the ‘oil roads’ we find on our country roads throughout the Dakotas. One of the reasons our equipment was purchased was that we are located in a similar weather environment.”

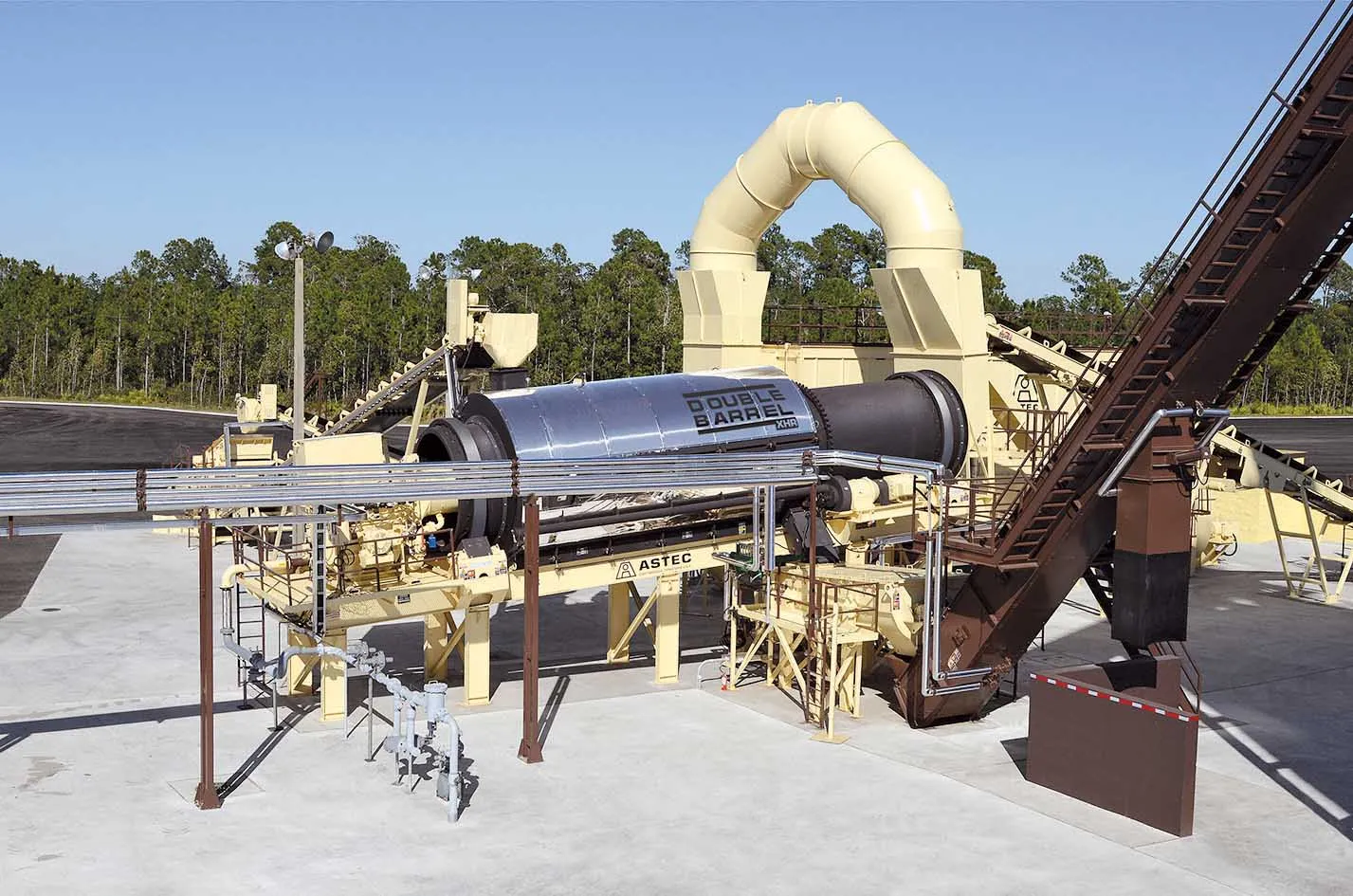

In addition to the pugmill system and conveyor, Skripal also purchased equipment from three other Astec Industries companies (681 Astec Industries, 1251 Heatec and Dillman) to complete the additive processing system and green portion of the system.

Nikolai Skripal and his wife, Svetlana, owners of Gazpromdorstroy Construction Company in Orenburg, Russia, visited the manufacturing facility to approve the shipment of its new KPI-JCI 52S Pugmill system and conveyor. The 52S Pugmill system is the first of its kind shipped from KPI to Russia, said Bruce Viau, international sales coordinator for Kolberg-Pioneer.

“The system that Gazpromdorstroy Construction Company has purchased will be used to build farm-to-market roads in the interior of Russia,” Viau said.

“Orenburg is located in the southern Ural Mountains near the border with Kazakhstan. The farm-to-market roads are similar to the ‘oil roads’ we find on our country roads throughout the Dakotas. One of the reasons our equipment was purchased was that we are located in a similar weather environment.”

In addition to the pugmill system and conveyor, Skripal also purchased equipment from three other Astec Industries companies (