Heavy equipment trailer specialist Kögel has developed two novel tipper trailers, featuring two and three axles.The two axle tipper trailer offers a load volume of 24m³ or 27m³ with a 4mm-thick Hardox 450 base and side walls made from aluminium. The advantage of the steel base with lightweight walls means that it can be used continuously for more than 10 years, while an aluminium trough would need repairs every two to three years.

March 14, 2013

Read time: 2 mins

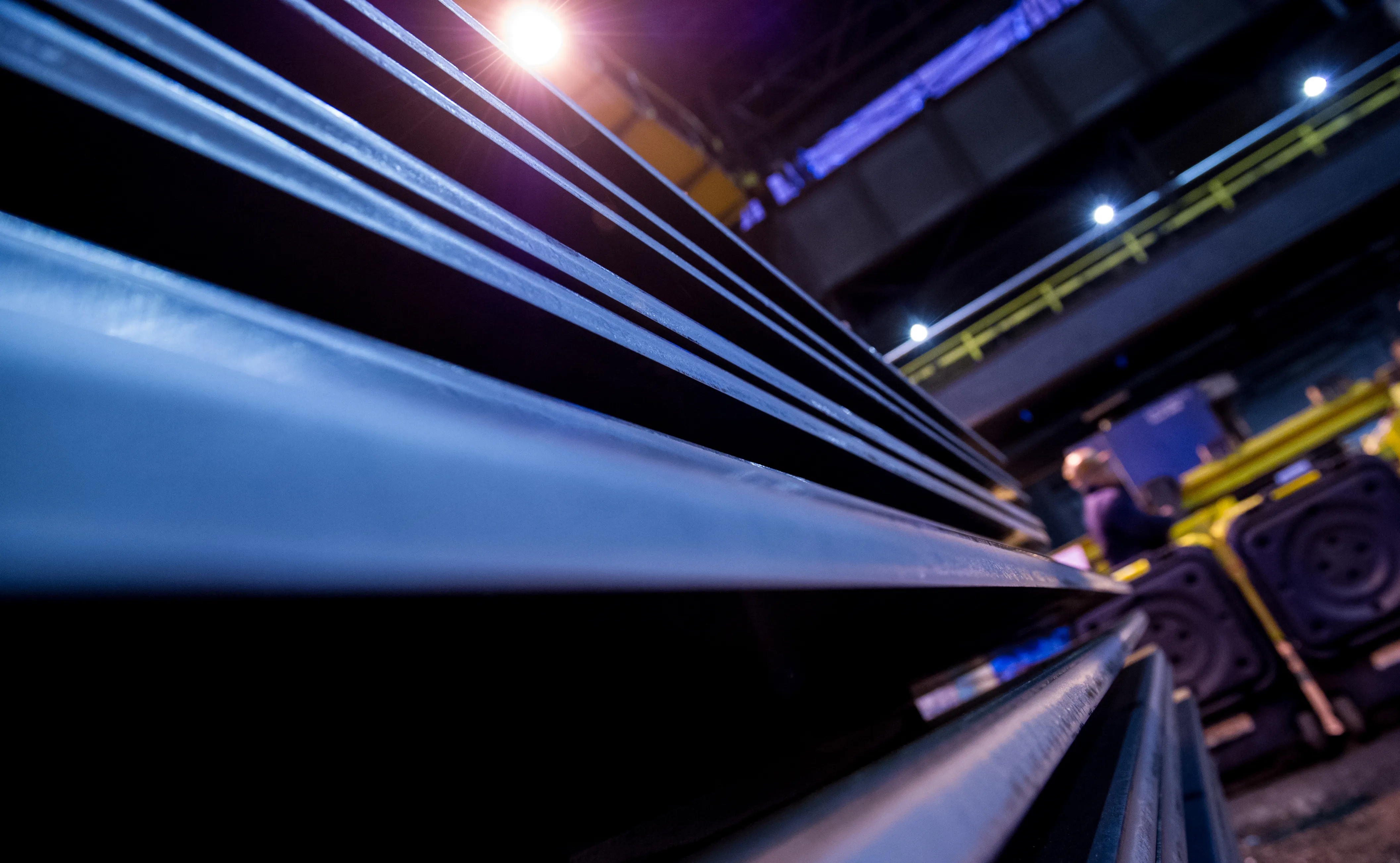

Heavy equipment trailer specialist 7223 Kögel has developed two novel tipper trailers, featuring two and three axles.The two axle tipper trailer offers a load volume of 24m³ or 27m³ with a 4mm-thick Hardox 450 base and side walls made from aluminium. The advantage of the steel base with lightweight walls means that it can be used continuously for more than 10 years, while an aluminium trough would need repairs every two to three years. This is suited to applications on building sites and in gravel pits. The three axle tipper trailer offers a load volume of 27m³, with a 4mm thick floor, back wall made from tempered Hardox 450 steel, and side walls made from extra-strong, 3mm S7090 steel sheet. The tipper trailer has a five-stage tipping cylinder with an angle of 48° for faster unloading. Different wall thicknesses are available while the modular design allows quick and cost-effective replacement of components and there is no need to fit expensive wear plates.

In addition, the Kögel Multi is a versatile trailer suited for the building materials transport business and for weather-resistant freight. The platform semi-trailer has a reinforced chassis and a semi-trailer load of 15tonnes in order to meet the increased load requirements in the construction industry.

The aluminium drop sides are said to be easy to remove from the hinges when required for the usage at hand. This makes the Multi ideal for transporting different building materials such as steel mesh, goods on pallets, and concrete parts. This is fitted with Kögel's new, optional MODULASI load-securing system and has a show load which is restrained accordingly.

In addition, the Kögel Multi is a versatile trailer suited for the building materials transport business and for weather-resistant freight. The platform semi-trailer has a reinforced chassis and a semi-trailer load of 15tonnes in order to meet the increased load requirements in the construction industry.

The aluminium drop sides are said to be easy to remove from the hinges when required for the usage at hand. This makes the Multi ideal for transporting different building materials such as steel mesh, goods on pallets, and concrete parts. This is fitted with Kögel's new, optional MODULASI load-securing system and has a show load which is restrained accordingly.

Stand: B4.310

View more stories