Kleemann will showcase the Mobicat MC 100 R mobile jaw crusher from its successful Contractor Line.

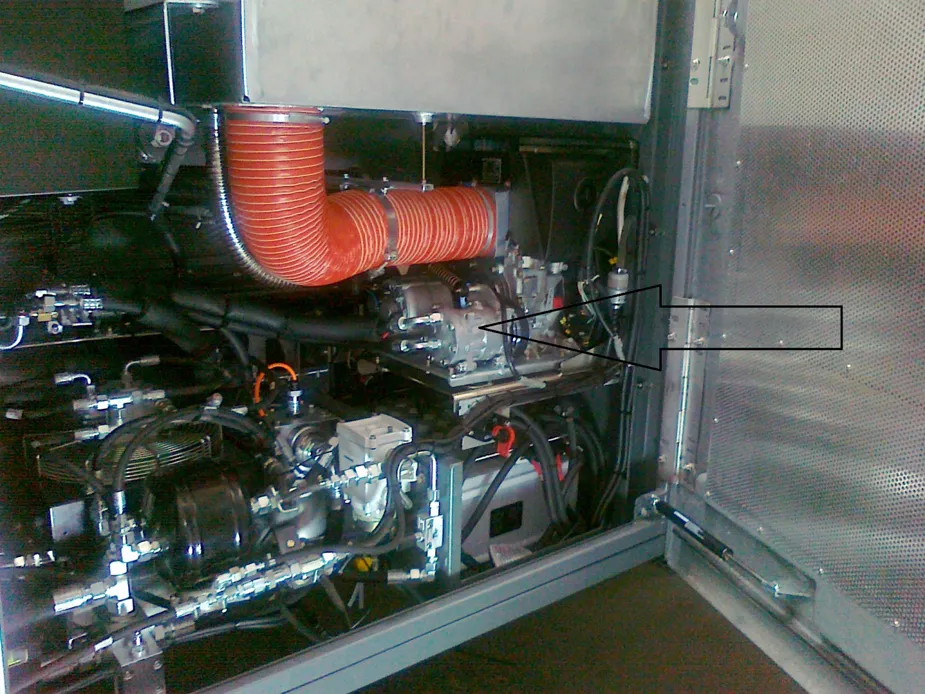

Weighing approximately 36tonnes it is relatively easy to transport and thus also ideal for smaller jobs, and there is the option to lower the crushing unit hydraulically to a height of 3,200mm for transport purposes. The powerful diesel engine with 228kW, together with the hydraulic crusher drive, ensures maximum feed capacity of up to 200 tonnes/hour, says Kleemann. The MC 100 R has sufficient power reserve

April 12, 2012

Read time: 2 mins

Weighing approximately 36tonnes it is relatively easy to transport and thus also ideal for smaller jobs, and there is the option to lower the crushing unit hydraulically to a height of 3,200mm for transport purposes.

The powerful diesel engine with 228kW, together with the hydraulic crusher drive, ensures maximum feed capacity of up to 200 tonnes/hour, says Kleemann.

The MC 100 R has sufficient power reserves to operate the crushers when the crushing jaw is full, and in the event of blockages in the crushing jaw, for example, due to large parts or reinforcing steel elements wedging, the reversible crusher drive helps the crusher to move again freely without any additional auxiliary means.

The infinitely variable gap setting is useful for frequently changing material as the plant can be adapted to new specifications in minimal time.

“The MC 100 R can thus be used more flexibly, be it for natural stone or in diverse recycling applications,” says Kleemann.

%$Linker:

Hall: 4 Stand: F012

%$Linker: