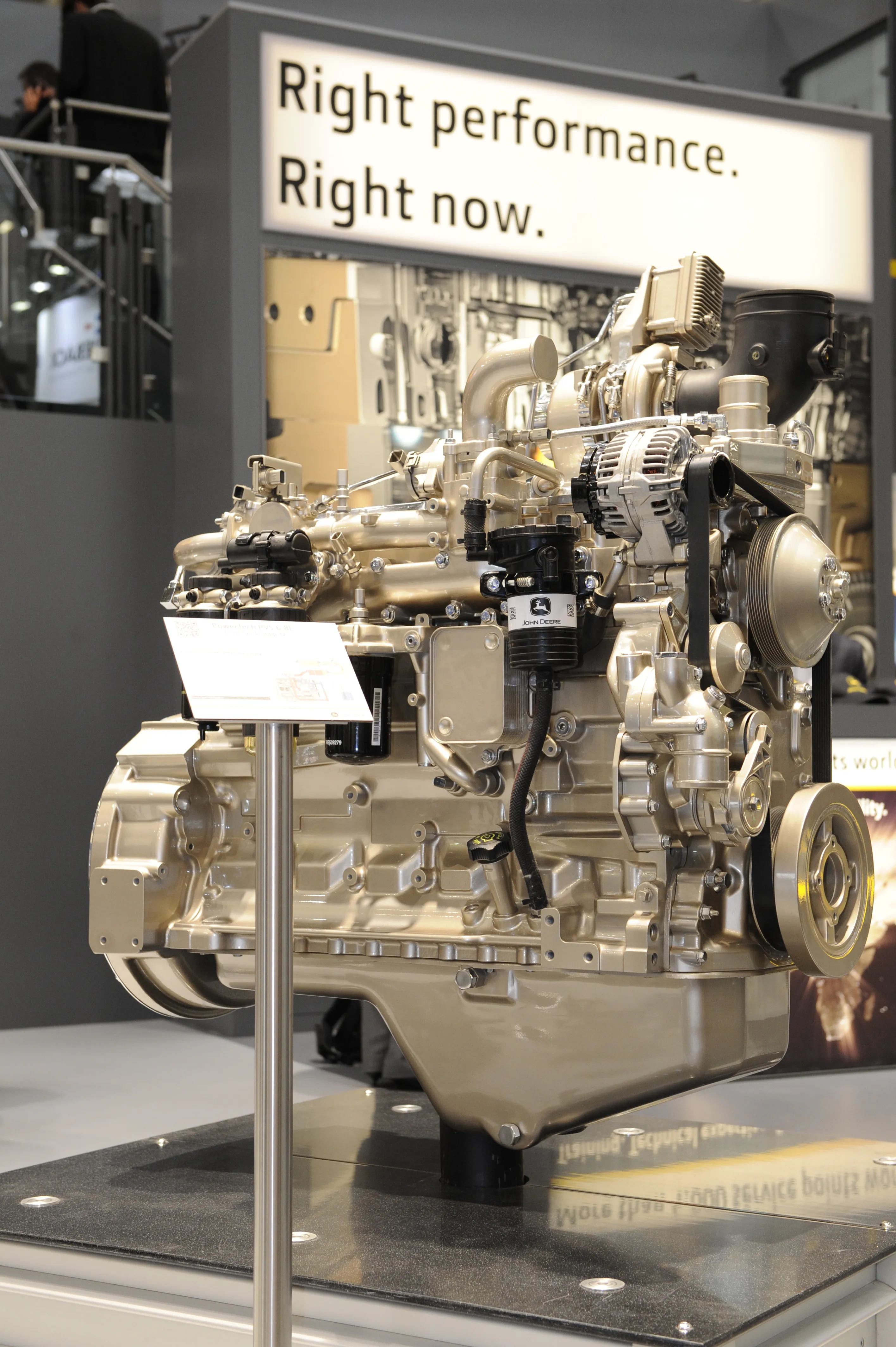

John Deere Power Systems used bauma to complete its engine line-up for Tier 4 Final/Stage IV emissions regulations. This included the arrival of the PowerTechTM PWL 4.5L engine, which meets emissions regulations without a diesel particulate filter (DPF). Spanning outputs from 63-104kW, this four-cylinder, 4.5litre engine offers reduced cost and improves engine packaging by eliminating the DPF, said Deere. However, the engine uses selective catalytic reduction (SCR), a diesel oxidation catalyst (DOC) and coo

April 18, 2013

Read time: 2 mins

This included the arrival of the PowerTechTM PWL 4.5L engine, which meets emissions regulations without a diesel particulate filter (DPF). Spanning outputs from 63-104kW, this four-cylinder, 4.5litre engine offers reduced cost and improves engine packaging by eliminating the DPF, said Deere.

However, the engine uses selective catalytic reduction (SCR), a diesel oxidation catalyst (DOC) and cooled exhaust gas recirculation (EGR) as part of its emissions control package.

“By eliminating the DPF, we have not compromised fuel efficiency or engine performance,” said Jean-Louis Mouchel, John Deere Power Systems’ director of engine marketing, sales and service for Europe, Africa, Middle East, Asia and Australia. “When it comes to total fluid cost – our diesel exhaust fluid consumption is around 1-3% – we have developed a cost-effective engine package for customers.

“Low diesel exhaust fluid consumption also means we can use a smaller fluid tank, minimising the installation space required on vehicles.”

In the lower power 36-55kW sector, John Deere Power Systems has introduced the three-cylinder 2.9litre PowerTech EWX 2.9L, using a two-valve cylinder head design, enabling the engine to use a combined DOC/DPF, without the need for cooled EGR or SCR.

“We are confident that all our solutions will deliver industry-leading performance and value while meeting required long-term emissions compliance,” said Mouchel.

These latest engine introductions give John Deere Power Systems a wide range of engine solutions for Tier 4 Final/Stage IV, spanning 36-448kW.

Stand: A5.219/320

%$Linker: