John Deere intends to use a package of technologies in its new diesels to achieve the low emissions performance required for Tier 4 Final/Stage IV compliance in the US and Europe. The regulations maintain the strict particulate matter (PM) emission levels established by Interim Tier 4/Stage III B regulations, while requiring an additional 80% reduction in nitrogen oxides (NOx). To meet Final Tier 4/Stage IV emissions regulations in some power categories, John Deere has developed what it calls the Integrated

January 6, 2017

Read time: 3 mins

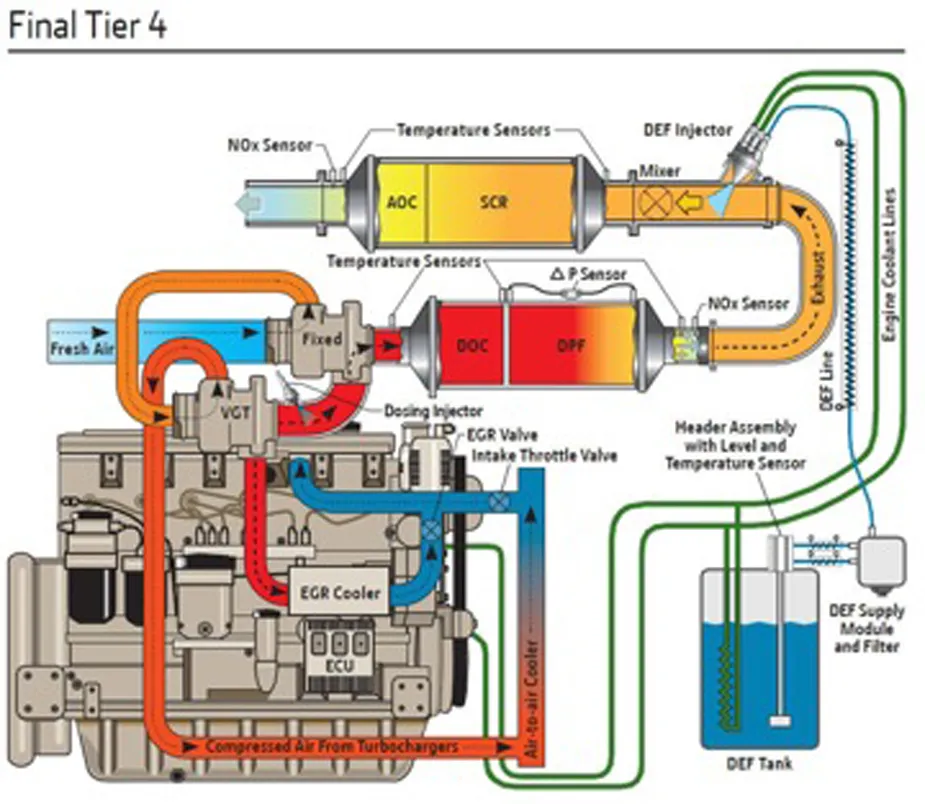

To meet Final Tier 4/Stage IV emissions regulations in some power categories, John Deere has developed what it calls the Integrated Emissions Control system. This is an optimised after-treatment solution coupled with the fuel-efficient Interim Tier 4/Stage III B engine platform, which features proven cooled exhaust gas recirculation (EGR). The John Deere Integrated Emissions Control system will use a diesel oxidation catalyst (DOC), diesel particulate filter (DPF) and a selective catalytic reduction (SCR). These modules have been specifically designed to meet the rigorous demands of off-highway applications

John Piasecki, director of worldwide marketing, sales and customer support for John Deere Power Systems said, “Exhaustive research and testing has determined that an application-specific SCR system that is well integrated with our proven Interim Tier 4/Stage III B engine platform will be the best solution to achieve Final Tier 4/Stage IV emissions compliance while delivering the power, performance, ease of operation, fluid efficiency, reliability and economical operating cost that our customers expect from John Deere.”

Consisting of an exhaust filter and SCR after-treatment components that are optimised and fully integrated, the new Integrated Emissions Control system will allow John Deere engines to consume less diesel exhaust fluid (AdBlue) than alternative Interim Tier 4 SCR technology solutions, according to the firm. Lower DEF consumption means the DEF tank size can be smaller. This makes installation into existing chassis easier, extends DEF filter service intervals and reduces operator involvement. Monitored and controlled by proprietary electronics within John Deere’s enhanced engine control unit (ECU), the Integrated Emissions Control system is also said to deliver fluid efficiency without sacrificing performance.

John Deere’s Final Tier 4/Stage IV technology solution is said to optimise performance and efficiency, which takes into account total fluid consumption including diesel fuel and additional fluids such as diesel exhaust fluid (DEF). These engines will run with conventional low-sulphur diesel as well as 5-20% biodiesel (B5-B20) blends that meet applicable

The firm says that the timing for the introduction of the engines will vary by model and territory but that deliveries will start during 2014 for larger than 130kW models and will be extended to lower power classes through 2016. This phased introduction matches differences in regulation date by engine power class.

As John Deere designs engines for OEM applications and its own construction machines the firm has expertise in integrating the engine with the drivetrain, hydraulics, electronic control unit (ECU), cooling package and other vehicle systems.

%$Linker:

Hall: 5B Stand: L002