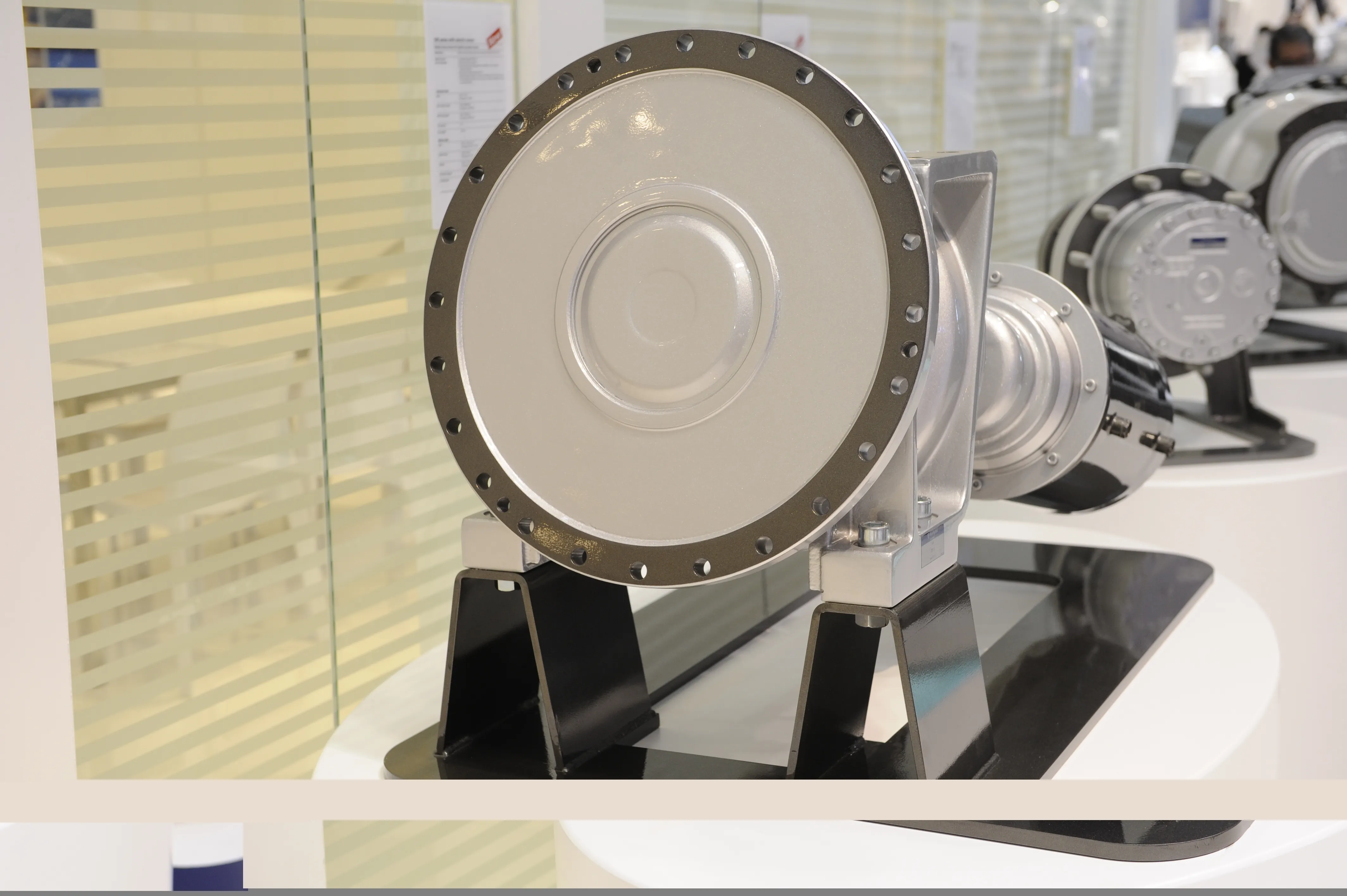

JCB has introduced two new soil compactors; the VM117D and the VM137D with operating weights of 11tonnes and 12.2tonnes respectively. The single-drum vibratory compactors can be used for a wide range of work in infrastructure and housing projects and have a smooth drum as standard with pad foot drums as an option. They are powered by JCB’s 93kW Stage IIIB/Tier 4 Interim Ecomax engines, which meet the emissions target without using a DPF and are said to deliver fuel savings of 16%. Changes to the compaction

April 16, 2013

Read time: 2 mins

The single-drum vibratory compactors can be used for a wide range of work in infrastructure and housing projects and have a smooth drum as standard with pad foot drums as an option.

They are powered by JCB’s 93kW Stage IIIB/Tier 4 Interim Ecomax engines, which meet the emissions target without using a DPF and are said to deliver fuel savings of 16%.

Changes to the compaction criteria (amplitude, frequency, centrifugal force, static linear load and weight distribution) are said to result in fewer passes being needed to achieve the required material density.

JCB’s latest intelligent compaction system (ICS) automatically and infinitely adjusts the amplitude and frequency settings, according to the achieved compaction results in improved fuel economy and productivity.

A range of compaction recording systems (compatronic) is available, from a basic system to compaction analysis system, combined with GPS tracking and a printer function to document the work. JCB’s Automatic Vibration Control automatic compaction control system is standard and designed to avoid over-compaction at the end of each pass.

The VM117 and VM137 machines will be manufactured in Germany, India and Brazil with Tier 2, BS3 and Tier 4i/Stage 3b engines for worldwide sales.

Stand: F7.713/1

%$Linker: