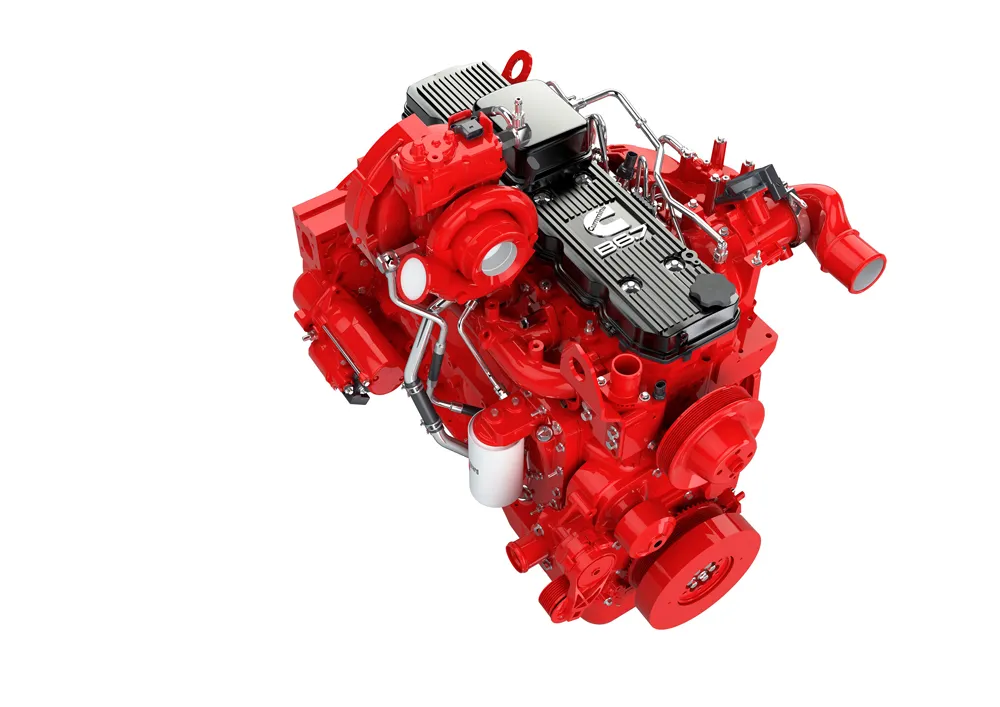

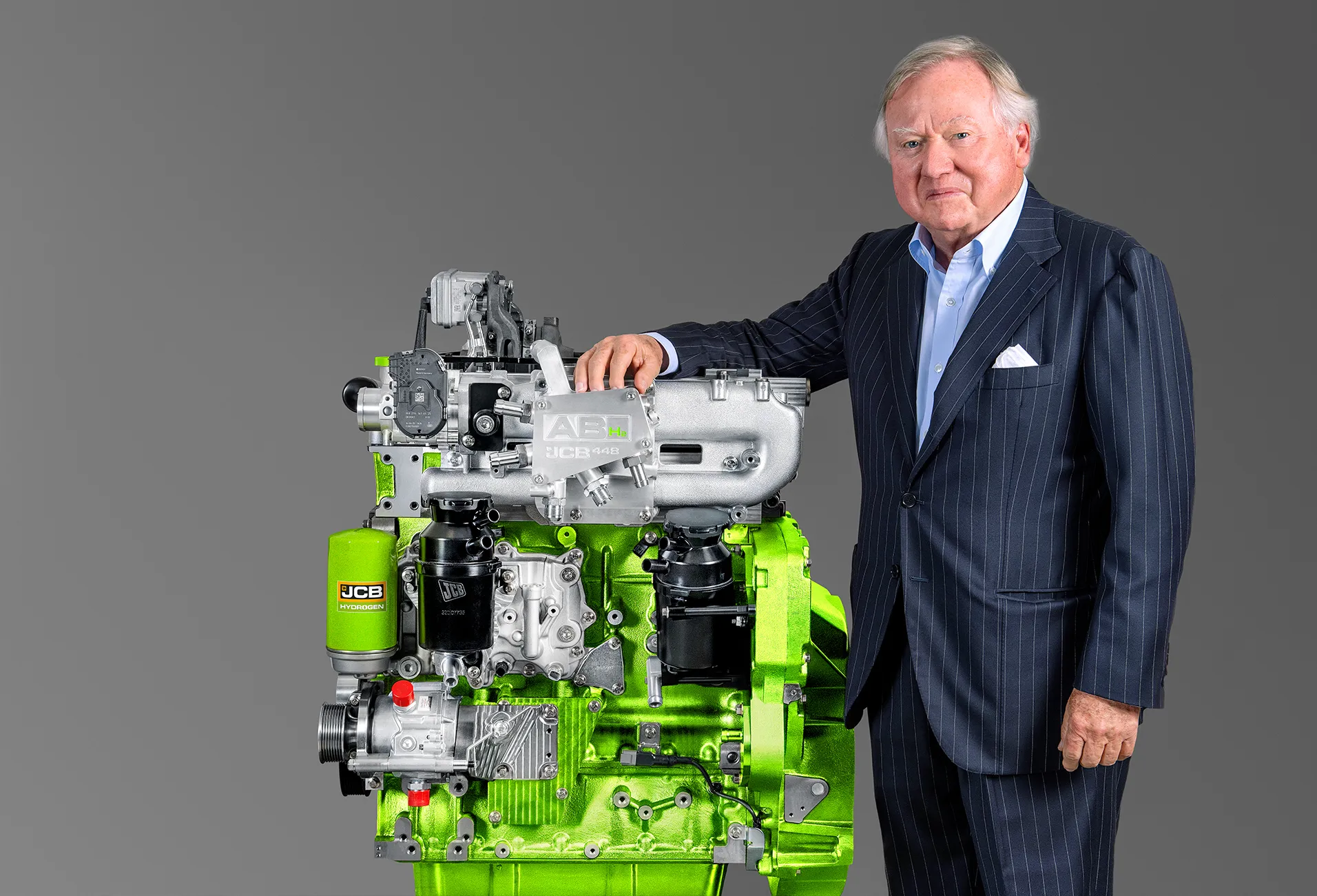

JCB has secured a ruling from licensing authorities allowing its hydrogen-fuelled engine to be used commercially in machines. JCB is the first construction equipment company to develop a fully working combustion engine fuelled by hydrogen and a team of 150 engineers has been working on the exciting £100 million development for over three years.

The company has confirmed that 11 licensing authorities across Europe have now given permission for JCB’s hydrogen engine to be sold across Europe – with authorities in other countries set to follow suit with certification in 2025.

JCB Chairman Anthony Bamford, who has led the company’s hydrogen engine project, said: “This is a very significant moment for JCB. To start the New Year with certification in place in so many European countries bodes very well for the future of hydrogen combustion technology. JCB has proved in recent years that it is a proper zero emissions solution for equipment.

“This formal type approval/certification paves the way for the sale and use of hydrogen engines right across the UK and Europe.”

This is a significant development and means that JCB will be well placed to win orders for off-highway machines fuelled by hydrogen. There is increasing pressure to use more sustainable technologies in construction. The Lower Thames Crossing project in the UK has specified that there will be no diesel machines onsite and that all mobile equipment will have to be either electric or hydrogen-fuelled. The decision for the project has yet to be made in May 2025 and if it goes ahead, there will be several firms able to supply suitable electric units, JCB included. But JCB will also be strongly-placed to win orders for hydrogen equipment needed for the project.

JCB confirmed that the Netherlands’ Vehicle Authority RDW was the first licensing authority to issue official certification, giving permission for the engine to sold in The Netherlands. Other licensing bodies across Europe have followed RDW’s lead by issuing the necessary certification, including Great Britain, Northern Ireland, Germany, France, Spain, Belgium, Poland, Finland, Switzerland and Lichtenstein. Licensing authorities in other countries are set to follow with certification during 2025.

JCB has already produced more than 130 evaluation engines which are powering backhoe loaders, Loadall telescopic handlers and generator sets. Real-world testing of JCB’s hydrogen equipment on customers’ sites is now at an advanced stage and progressing well.