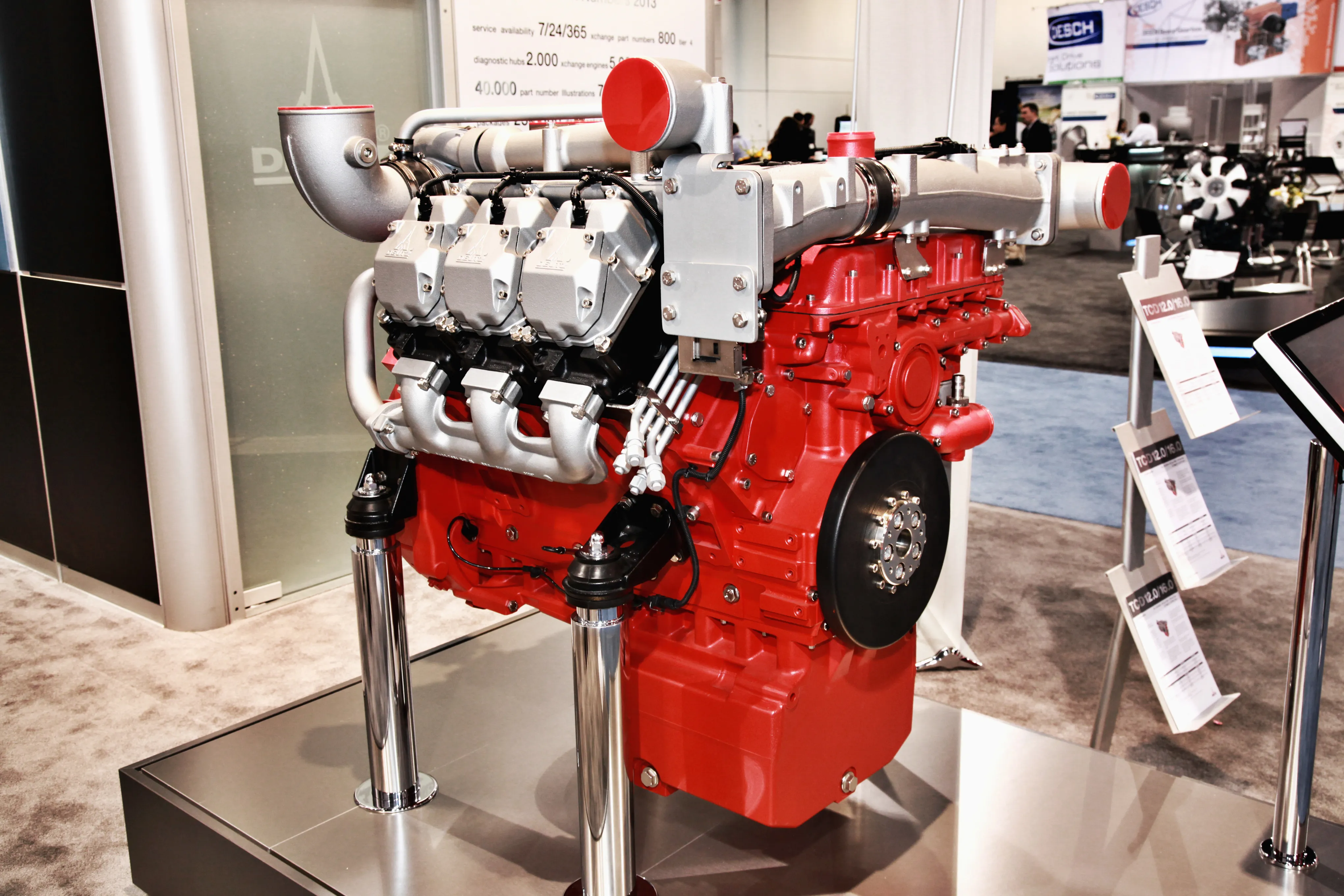

JCB’s Ecomax engine – the company’s innovative solution to EU Stage IIIB/US Tier 4 emissions legislation - will be on show for the first time at bauma as machines powered by it make their debut. The UK-based construction equipment manufacturing giant claims it is the only leading equipment manufacturer in the world to have met the stringent Stage IIIB/Tier 4 interim emissions legislation without the use of diesel particulate filter (DPF) or after-treatment – resulting in the world’s cleanest and most effici

January 6, 2017

Read time: 2 mins

The UK-based construction equipment manufacturing giant claims it is the only leading equipment manufacturer in the world to have met the stringent Stage IIIB/Tier 4 interim emissions legislation without the use of diesel particulate filter (DPF) or after-treatment – resulting in the world’s cleanest and most efficient off-highway engine.

The use of innovative in-cylinder technologies (patent pending) resulting in a cleaner, more efficient combustion process, is how JCB says it has met the emissions legislation. This is said to have eliminated the need for any external exhaust after-treatment, significantly reducing operating costs.

Said to build on the success of the original Dieselmax engine and retaining key features such as high torque at low engine revs, robustness, reliability, and low noise and vibration, the Ecomax is said to be the result of a US$124.1 million (£80m) investment programme.

As well as the obvious environmental benefit of a reduction in emissions, the JCB Ecomax engine is also said to offer customers improved torque throughout the rev range, coupled with noticeably reduced fuel consumption.

The no-after treatment approach is also said to allow the introduction of an innovative recalibration option, making it possible for JCB dealers to recalibrate the Ecomax engine to lower injection pressures and turn off the EGR function, without any hardware changes.

The Ecomax’s new electronic ECU has been integrated with JCB LiveLink advanced telematics system. As well as location information, routine service notifications and critical machine health alerts, JCB LiveLink is said to offer customers remote access to full Ecomax engine diagnostics and fuel economy data via the internet or through their mobile phones.

The JCB Ecomax engine range will be fitted into machines spanning the 54.42kW to 127.24kW range, including JCB backhoe loaders, Loadall telescopic handlers, wheeled loading shovels, the TM range of telescopic boom wheeled loaders, JS excavators, rough terrain forklifts and skid steer loaders.

Stand: A5.321/420

%$Linker: