JCB has announced plans to start production of six-cylinder engines with the addition of the JCB Dieselmax 672 to its world renowned engine line-up. In just over eight years JCB has gone from a new entrant to engine manufacturing to a major global producer with a reputation for fuel efficiency and innovation. The first engine rolled off the production line in the UK in November 2004 and since then production has also extended to JCB India’s HQ at Ballabgarh, where the first engine was manufactured in 2011.

June 7, 2013

Read time: 3 mins

In just over eight years JCB has gone from a new entrant to engine manufacturing to a major global producer with a reputation for fuel efficiency and innovation. The first engine rolled off the production line in the UK in November 2004 and since then production has also extended to JCB India’s HQ at Ballabgarh, where the first engine was manufactured in 2011. To date more than 250,000 engines have been produced globally.

The introduction of the new six-cylinder engine represents an investment of around US$69.6 million (£45mn) and by the time it goes into full production, its launch will have created more than 50 new jobs.

“The move into six-cylinder engine production is a historic moment for our business and a natural step to take and we look forward to setting new standards in performance and fuel efficiency,” said JCB chairman Sir Anthony Bamford.

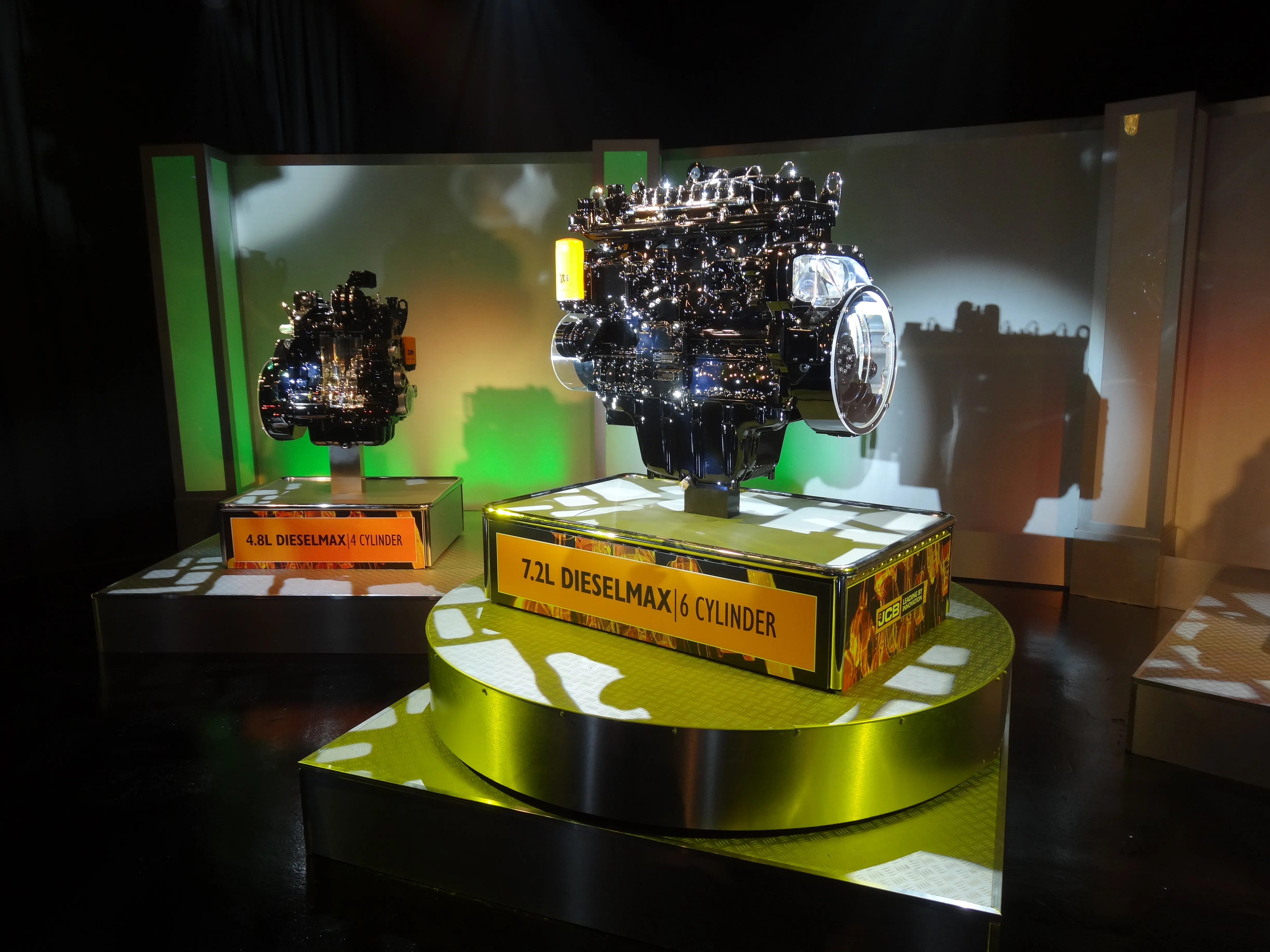

The JCB Dieselmax 672 is based on the company’s successful four-cylinder 4.8-litre Dieselmax engine, with a high degree of parts commonality across the two engine platforms. In production for more than eight years, with many engines running reliably after more than 20,000 hours of service around the world, the Dieselmax engine features electronic control, Delphi common rail fuel injection and fixed geometry turbocharging.

Initially the Dieselmax 672 will be produced to meet Stage II emissions standards, for growth markets including Russia, Brazil and China. The engine will be seen first in JCB’s JS360 crawler excavator for those territories, but will be used in additional machines as time progresses.

The six-cylinder engine will be offered with ratings of 140kW (188hp), 165kW (221hp), 190kW (255hp) and with a maximum output of 225kW (302hp). Maximum torque of the JCB Dieselmax 672 is 1,200Nm. JCB says it has managed to produce an incredibly efficient engine in the Dieselmax 672, said to promise up to an 8% increase in fuel efficiency compared to previous engines in the JS excavator line. In testing, the 7.2-litre engine is said to have recorded a specific fuel consumption of just 189g/kWh, while delivering excellent performance and rapid response.

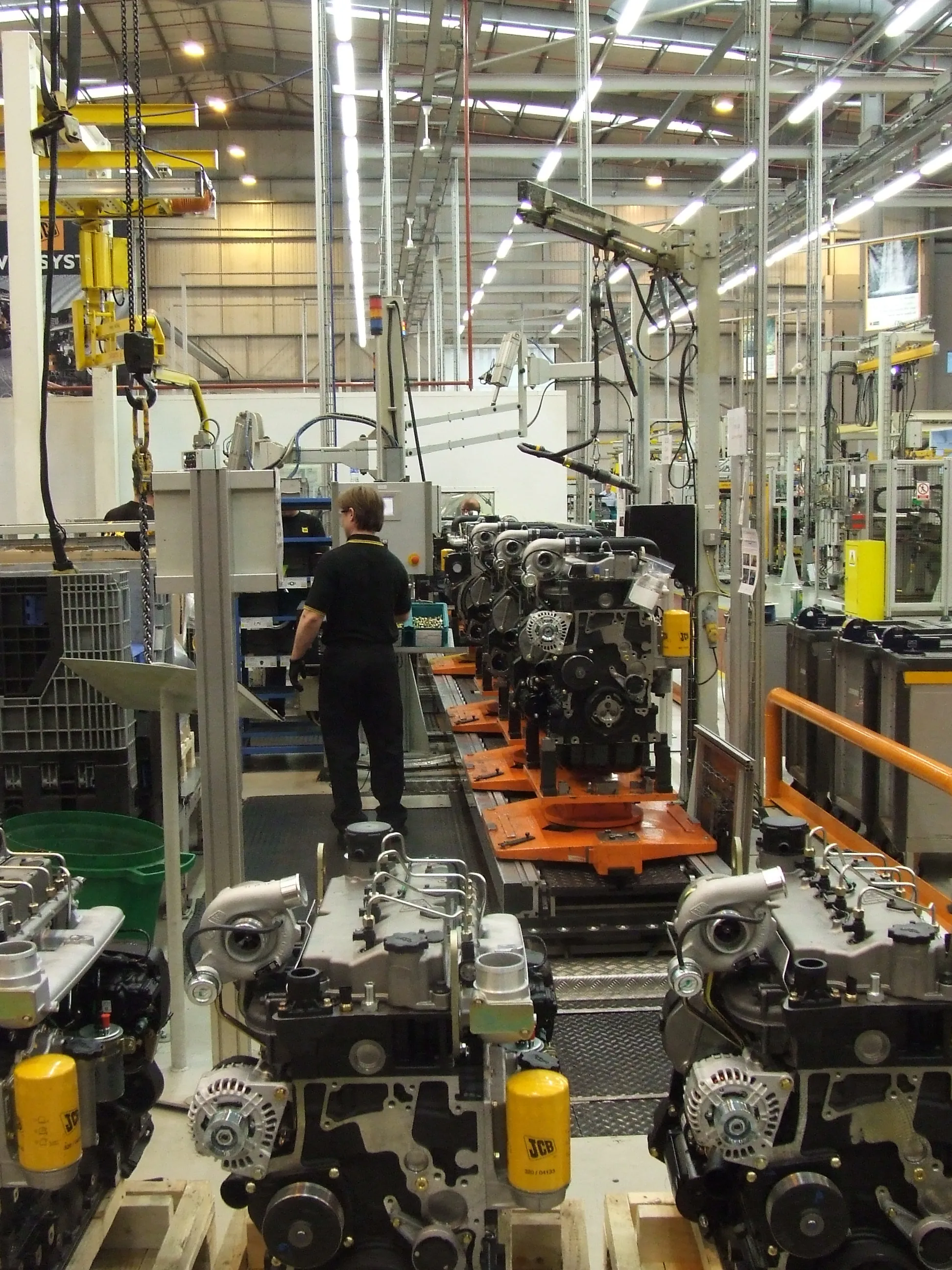

The six-cylinder engines will be built on a dedicated line at JCB Power Systems’ modern purpose-built facility in Foston, Derbyshire, central England. In development for more than two years, the engines have already completed more than 50,000 hours of testing, 30,000 of which have been in machines working in the field.

The Dieselmax engines have 500-hour service intervals, maintaining low operating costs and maximum uptime for customers. The engines will also be offered as part of the company’s OEM product line, for use in non-JCB machinery.

“The six-cylinder Dieselmax 672 is the ultimate expression of our Dieselmax engine design philosophy,” said Alan Tolley, director of engine programmes at JCB Power Systems.

“Through the use of innovative engine design and technological development we have produced a reliable, highly durable and incredibly fuel efficient engine, that will go on to power our larger equipment in many markets around the world.”

In 2006, two four-cylinder Dieselmax engines successfully powered JCB’s record-breaking Dieselmax car to a world land speed record of 563kmh (350mph) on the Salt Flats of Bonneville, USA. The engineering expertise involved in that successful record attempt is said to have been invested in the development of this latest addition to the JCB engine family.