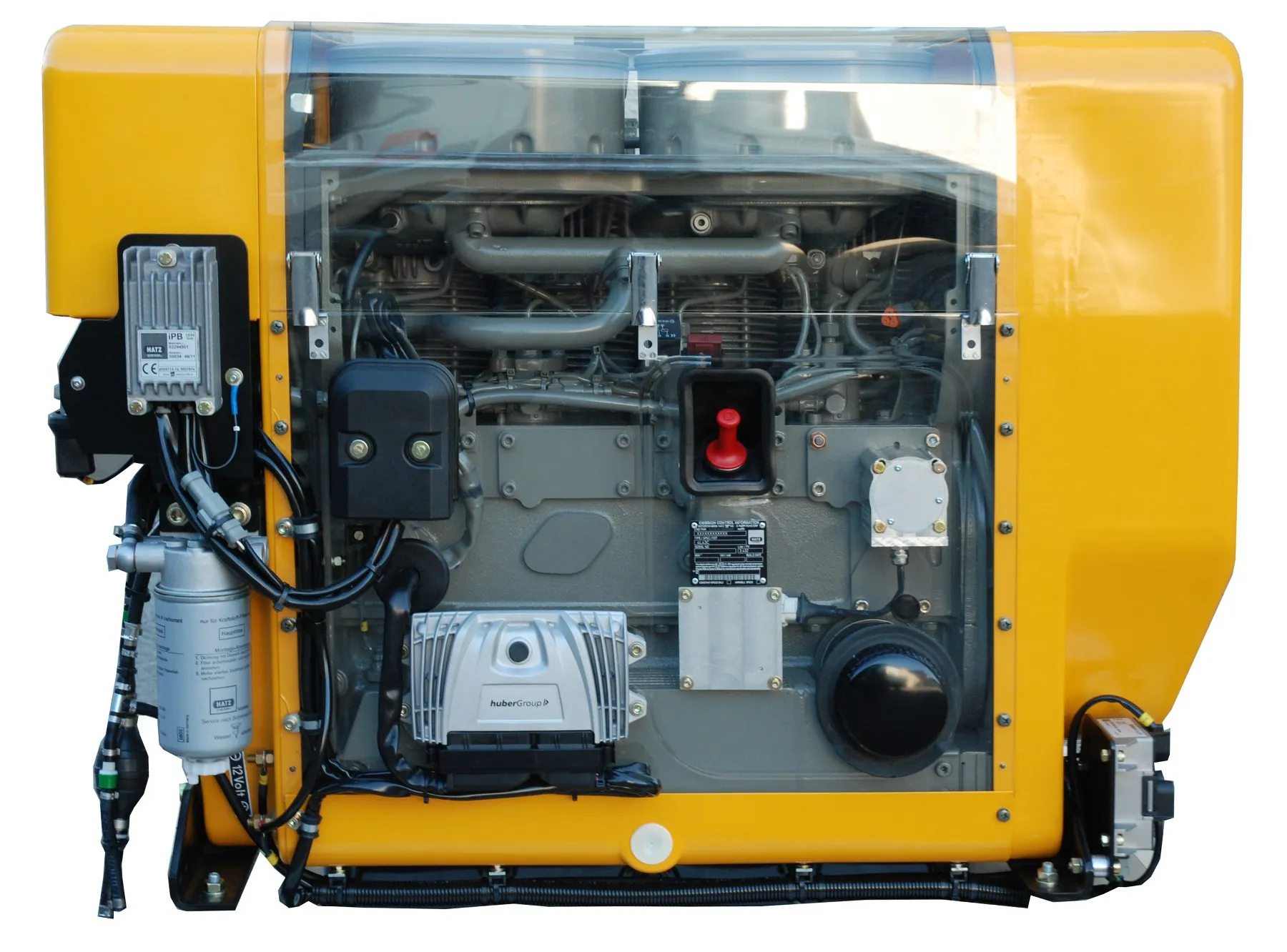

JCB says its Ecomax Stage 4/Tier 4 Final engine can be engineered into many existing machines without needing additional space by using a ‘one can’ selective catalytic reduction (SCR). According to the company’s chief technology officer, Tim Burnhope, in many cases the mini SCR on the Stage 4/Tier 4 Final Ecomax engine can be positioned in the same space occupied by the exhaust silencer on previous generations. He said, “Our engine is already so clean that we only need 2% to 3% of urea, which allows us to u

January 6, 2017

Read time: 2 mins

According to the company’s chief technology officer, Tim Burnhope, in many cases the mini SCR on the Stage 4/Tier 4 Final Ecomax engine can be positioned in the same space occupied by the exhaust silencer on previous generations.

He said, “Our engine is already so clean that we only need 2% to 3% of urea, which allows us to use a very compact SCR system. Many of our competitors have two or three canisters – one for the SCR, one for a DOC and another for a DPF – and that requires a lot more space.” Our SCR is so compact that, in many cases, there is no need for any bodywork alterations.”

The new engine is said to be 5% more fuel efficient than the Stage IIIB/Tier 4 Interim version, which is itself some 10% more economical than the Stage IIIA version. In its Stage IIIB/Tier 4 Interim guise the Ecomax engine has exhaust gas recirculation and variable turbocharger geometry but does not require a DPF. Power ratings now go up to 129kW, meaning JCB is now fitting the Ecomax in excavators up to the 22tonnes operating weight JS220.

According to Burnhope, the Ecomax is 10% more fuel efficient than the engine it replaces and would save a typical JS220 owner €5,200 in fuel over three years.

When asked during a press conference if a six-cylinder version of the Ecomax was likely in the near future, the company said, “We consider all options and the deciding factor is whether it will save the customer fuel.”

Stand: F7.713/1

%$Linker: