New Intrame products were on display at INTERMAT Paris. They included the mixer from a Flow-Mix 220 continuous asphalt plant, driven by two 30 kw gear boxes and set for delivery in France.

April 24, 2015

Read time: 1 min

New

They included the mixer from a Flow-Mix 220 continuous asphalt plant, driven by two 30 kw gear boxes and set for delivery in France.

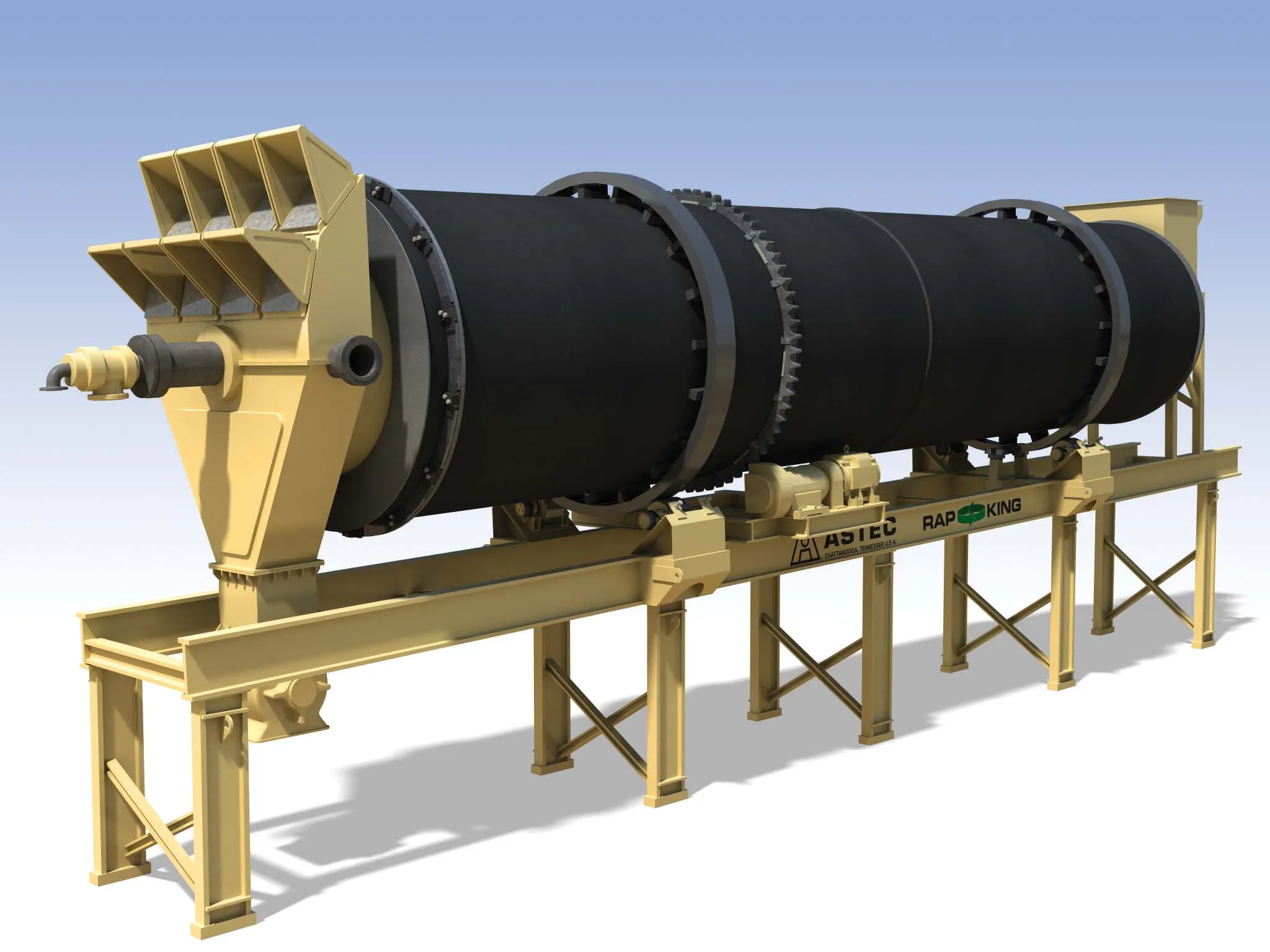

“The plant is also equipped with a special dryer, which is extended to enable high rates of recyclables,” said Antonio Morón Hodge, general manager of Intrame. “The plant has the capability of utilising up to 50% of RAP.”

Also featured was the new control cabin for a Flow-Mix 140, to be delivered in France as well. It includes the ASFLOW 10 control system, which features Ethernet IP communications.

Another product on display was the mixing tower of a 120 t/h batch type ultramobile plant to be delivered to Algeria.