“Developments in metallurgy have helped to strengthen components and lead to increased injection pressures, typically up to 2400 bar,” said Scania industrial engine sales director, Bernt Gustavsson.

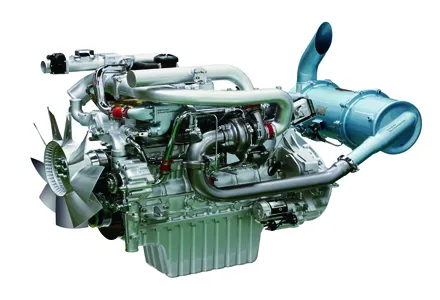

“A compact DOC is neatly integrated into the SCR system, which saves on space needed for those with installation constraints.”

Mr Gustavsson says its modular development programme for its inline five- and six-cylinder platforms, plus the 16-litre V8 engine, has enabled refinement of combustion and cooled EGR processes – it is technology that the company has a lot of experience with, and which it employs for its on-road truck and bus applications.

“We may need to add an exhaust brake on engines operating under light duty cycles to raise the exhaust temperature so that SCR remains effective at very light loads,” he said.

%$Linker:

Hall: 5A Stand: G151