Following the successful integration of CDC Dynamic Load Control management in its agricultural telehander range, Merlo is introducing the technology to its construction models at INTERMAT The system is an advanced method of load management, and effectively places a real-time image of the handler’s load chart on a colour screen in the cab, showing the weight and position of the load on the chart, at all times.

January 6, 2017

Read time: 2 mins

Following the successful integration of CDC Dynamic Load Control management in its agricultural telehander range, 2922 Merlo is introducing the technology to its construction models at INTERMAT.

The system is an advanced method of load management, and effectively places a real-time image of the handler’s load chart on a colour screen in the cab, showing the weight and position of the load on the chart, at all times.

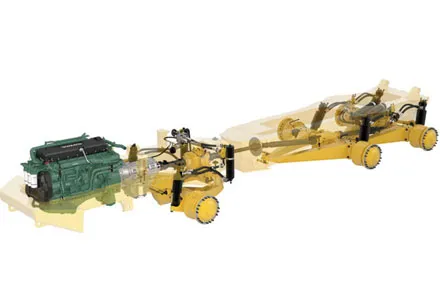

Merlo has achieved this by moving away from relying solely on strain gauges mounted between the rear axle and chassis - as used to monitor forward roll-overs to EN15000 specification - and instead relies on a pressure sensor in the main lift ram combined with a boom angle sensor and measurement of the telescopic boom extension, to plot the load onto the chart.

Working in real-time, the dynamic load control continuously weighs the load and is accurate to within 50kg, said the Italian telehandler maker. Should the operator attempt to work outside the parameters of the load chart and the capabilities of the handler, CDC will restrict boom movements ensuring the operator can only lower and retract the boom to ensure the handler remains in a safe working condition.

In addition, every attachment that is used with the loader - for example pallet forks, bucket, man basket – will contain an embedded chip that is scanned by the handler’s headstock each time an attachment is changed.

This enables the CDC system to automatically select the correct load chart for the attachment being used, to prevent the operator from over-riding the system. Merlo has also fitted a default map setting that enables non-coded attachments to continue to work with dynamic load control.

2 Internal 2 4824 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/intermat-2012/video/ true false %>

The system is an advanced method of load management, and effectively places a real-time image of the handler’s load chart on a colour screen in the cab, showing the weight and position of the load on the chart, at all times.

Merlo has achieved this by moving away from relying solely on strain gauges mounted between the rear axle and chassis - as used to monitor forward roll-overs to EN15000 specification - and instead relies on a pressure sensor in the main lift ram combined with a boom angle sensor and measurement of the telescopic boom extension, to plot the load onto the chart.

Working in real-time, the dynamic load control continuously weighs the load and is accurate to within 50kg, said the Italian telehandler maker. Should the operator attempt to work outside the parameters of the load chart and the capabilities of the handler, CDC will restrict boom movements ensuring the operator can only lower and retract the boom to ensure the handler remains in a safe working condition.

In addition, every attachment that is used with the loader - for example pallet forks, bucket, man basket – will contain an embedded chip that is scanned by the handler’s headstock each time an attachment is changed.

This enables the CDC system to automatically select the correct load chart for the attachment being used, to prevent the operator from over-riding the system. Merlo has also fitted a default map setting that enables non-coded attachments to continue to work with dynamic load control.

%$Linker:

Outside: E5 Stand: B002

%$Linker: