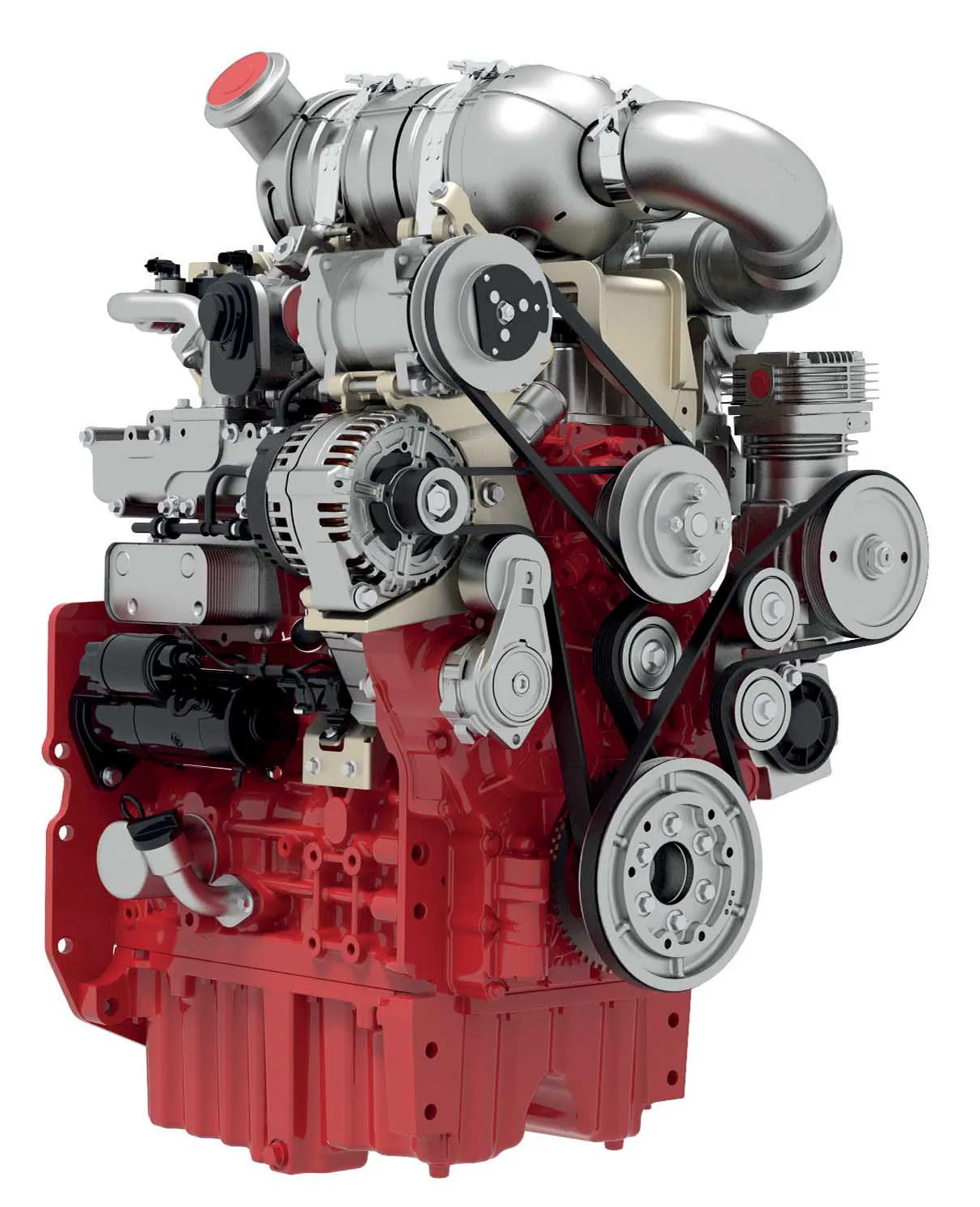

And with cutting-edge combustion chamber management, the engine maker said customers can also expect fuel savings of up to 5%.

With its TCD 3.6 L engine, the firm has achieved a state of emissions cleanliness using a diesel oxidation catalyst (DOC) and selective catalytic reduction (SCR) exhaust after-treatment. From 4.1 to 16 litres (TCD 4.1L to TCD 16L) the engine range will be using a diesel particulate filter and SCR after-treatment.

“With the new engine ratings, we can give our customers the option of down-sizing – to replace a large-displacement Tier 3 engine with a smaller Tier 4 engine that delivers a higher power density,” said Deutz media relations manager Frank Wesolowski. “This also compensates for the additional cost for cooling and emissions control systems.”

Mr Wesolowski adds that the D-Vert system is modular and makes it possible to de-tier an engine if necessary, for example, for those exporting secondhand equipment to markets that do not need to meet such legislation.

%$Linker:

Hall: 5B Stand: K042