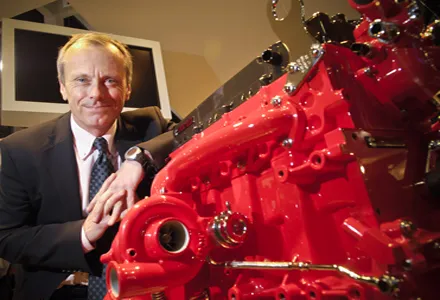

Cummins has revealed its latest engine platform to cover the 37-55kW sector. Called the QSF2.8, the new four-cylinder platform is the smallest engine from Cummins to use full-authority electronic controls for high-pressure common rail injection. The 2.8litre engine is available in naturally aspirated (37kW) and turbocharged (55kW) packages, and has been developed as a global engine platform.

January 6, 2017

Read time: 1 min

RSS196 Cummins has revealed its latest engine platform to cover the 37-55kW sector.

Called the QSF2.8, the new four-cylinder platform is the smallest engine from Cummins to use full-authority electronic controls for high-pressure common rail injection.

The 2.8litre engine is available in naturally aspirated (37kW) and turbocharged (55kW) packages, and has been developed as a global engine platform.

“The QSF2.8 brings new power capability to many OEMs,” said Hugh Foden, executive director of Cummins off-highway business.

“Combining a sculpted cylinder block design with composite materials for the oil pan, oil filter and valve cover, we’ve been able to keep the wet weight of the QSF2.8 to just 230kg.”

Called the QSF2.8, the new four-cylinder platform is the smallest engine from Cummins to use full-authority electronic controls for high-pressure common rail injection.

The 2.8litre engine is available in naturally aspirated (37kW) and turbocharged (55kW) packages, and has been developed as a global engine platform.

“The QSF2.8 brings new power capability to many OEMs,” said Hugh Foden, executive director of Cummins off-highway business.

“Combining a sculpted cylinder block design with composite materials for the oil pan, oil filter and valve cover, we’ve been able to keep the wet weight of the QSF2.8 to just 230kg.”

Hall: 5B Stand: M027