INTERMAT 2015 is the scene of some major innovations for the equipment sector.

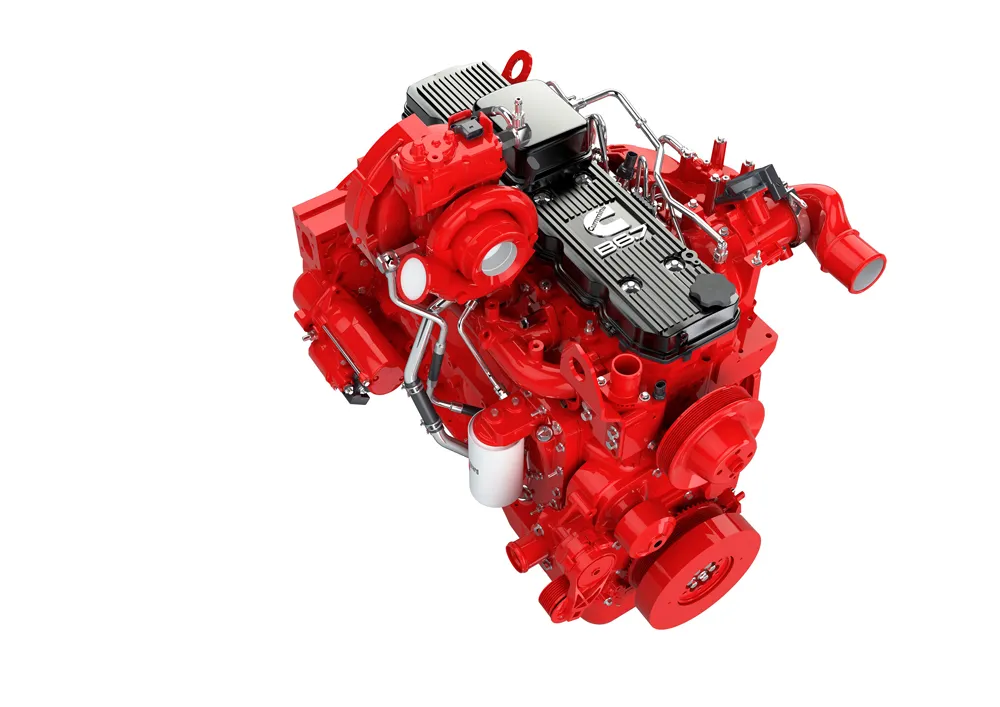

Much of the focus is again on the engine sector with the likes of Cummins, Deutz, Kohler/Lombardini, MTU and Yanmar all amongst those suppliers unveiling new low emission diesels. These new engines are cleaner than ever before while also offering benefits in terms of lowered fuel consumption and extended service intervals.

Developments in machine control technologies too offer major performance gains with key suppliers like Leica Geosystems, MOBA, Topcon and Trimble all offering a wider scope of solutions for contractors that will boost efficiency and cut construction time.

And of course all the major manufacturers are introducing new machines. Bell Equipment, Case CE, the Fayat Group, Hidromek, Hitachi, Hyundai, Komatsu, LiuGong, Powerscreen, Shantui, Terex (Finlay), Volvo CE, the Wirtgen Group and Zoomlion are all amongst those companies unveiling new equipment innovations.