Italian hydraulic breaker manufacturer Indeco is introducing a new approach to selecting tunnelling methods. The firm says that this has been developed in response to a tunnelling industry that is too-ready to select tunnel boring machines (TBMs).

January 6, 2017

Read time: 2 mins

Italian hydraulic breaker manufacturer Indeco is introducing a new approach to selecting tunnelling methods.

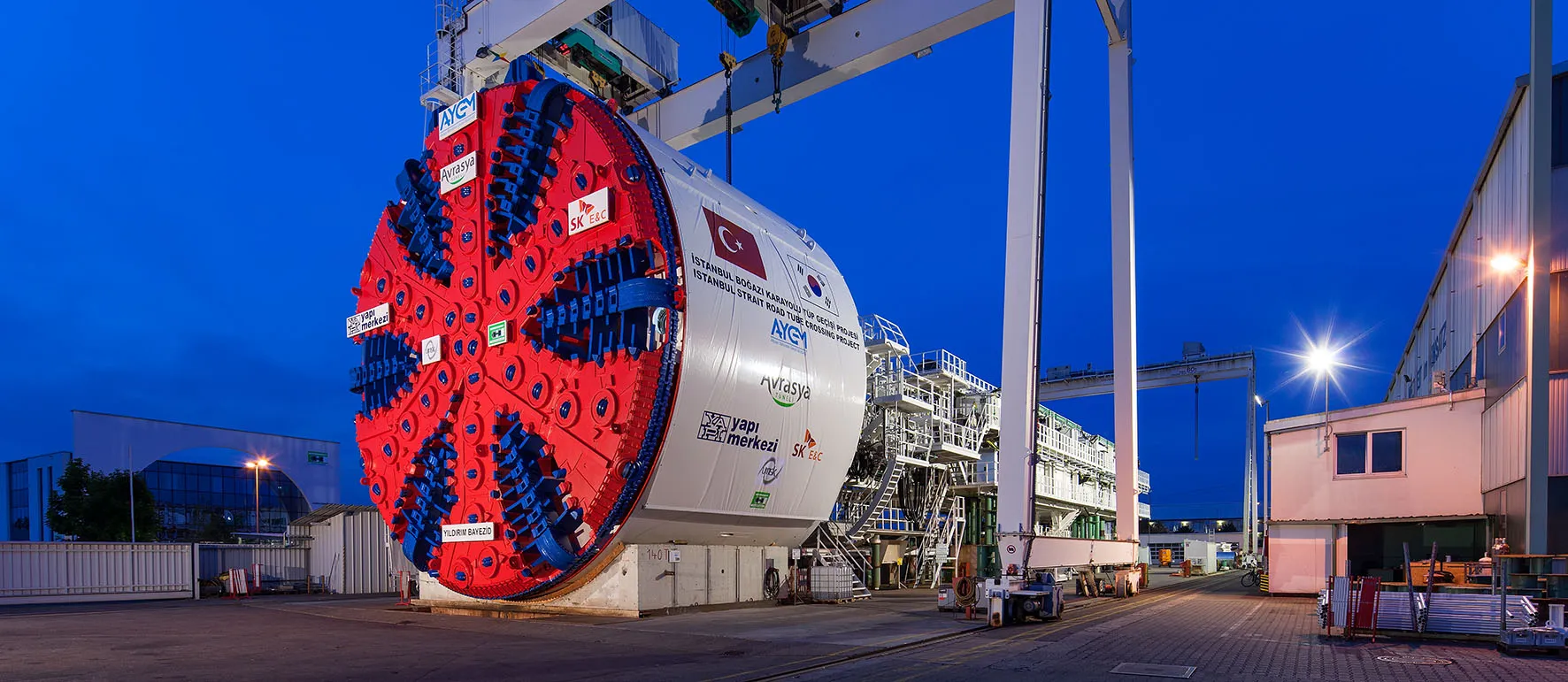

The firm says that this has been developed in response to a tunnelling industry that is too-ready to select tunnel boring machines (TBMs).237 Indeco’s marketing and commercial manager, Michele Vitulano explained that TBMs are highly efficient in the right conditions and have achieved major successes in a number of projects. However, he said also that these machines are also hampered by a lack of versatility. Changes in rock conditions can cause serious problems such as excessive cutter wear or even breakdowns.

Mauro Amato, product and project manager at Indeco explained that the firm has developed an Analytical Hierarchy Process (AHP) that provides a simplified process for selecting the best excavation method for a tunnelling project.

In Italy tunnelling projects are often carried out using hydraulic breakers fitted to excavators, with loading and hauling equipment to carry away the waste materials. Vitulano asked, “Why are Italian companies working like that?”

And he explained that the complex geology of Italy has meant that for many tunnelling projects, the conditions are not sufficiently homogenous to allow the use of TBMs. Hydraulic breakers have been well proven in tunnelling applications in Italy, as they suit the often fractured or faulted rock conditions. This equipment is comparatively inexpensive, as well as being reliable and versatile. A TBM by comparison is highly expensive to purchase and also requires considerable logistics to supply and install on site.

When fitted to an excavator, a hydraulic breaker provides a highly versatile method. It can be used as a back up to a TBM for difficult tunnelling conditions, as well as playing a similar role with drilling and blasting methods. Alessandro Ciccolella is research and development manager at Indeco and said, “Using a breaker, a contractor can follow fault lines of the rock and increase productivity. It is a precision tool that allows selective excavation.”

He added, “There is a risk factor with a TBM that is totally overlooked by the tunnelling industry. Blasting and breaking are not methods of the past for tunnelling. That’s what we want to highlight.”

The firm says that this has been developed in response to a tunnelling industry that is too-ready to select tunnel boring machines (TBMs).

Mauro Amato, product and project manager at Indeco explained that the firm has developed an Analytical Hierarchy Process (AHP) that provides a simplified process for selecting the best excavation method for a tunnelling project.

In Italy tunnelling projects are often carried out using hydraulic breakers fitted to excavators, with loading and hauling equipment to carry away the waste materials. Vitulano asked, “Why are Italian companies working like that?”

And he explained that the complex geology of Italy has meant that for many tunnelling projects, the conditions are not sufficiently homogenous to allow the use of TBMs. Hydraulic breakers have been well proven in tunnelling applications in Italy, as they suit the often fractured or faulted rock conditions. This equipment is comparatively inexpensive, as well as being reliable and versatile. A TBM by comparison is highly expensive to purchase and also requires considerable logistics to supply and install on site.

When fitted to an excavator, a hydraulic breaker provides a highly versatile method. It can be used as a back up to a TBM for difficult tunnelling conditions, as well as playing a similar role with drilling and blasting methods. Alessandro Ciccolella is research and development manager at Indeco and said, “Using a breaker, a contractor can follow fault lines of the rock and increase productivity. It is a precision tool that allows selective excavation.”

He added, “There is a risk factor with a TBM that is totally overlooked by the tunnelling industry. Blasting and breaking are not methods of the past for tunnelling. That’s what we want to highlight.”