Legacy Building Solutions has designed and built two new salt storage and winter de-icing operation facilities for Indiana Department of Transportation (INDOT) in the United States. The tension fabric structures, situated near Markle and Westfield, provide each site with a salt storage capacity of 2,993tonnes — enough to cover several months of winter road maintenance.

June 13, 2012

Read time: 2 mins

The tension fabric structures, situated near Markle and Westfield, provide each site with a salt storage capacity of 2,993tonnes — enough to cover several months of winter road maintenance.

“We were storing salt in older salt domes that do not have enough capacity for our average annual use,” says Steve McAvoy, state facilities manager for INDOT. “The new Legacy buildings address that issue. They were also designed so trucks could enter the building single file to load and off-load under a roof in a safe and controlled manner. The configuration is much more efficient and has already saved us time and money.”

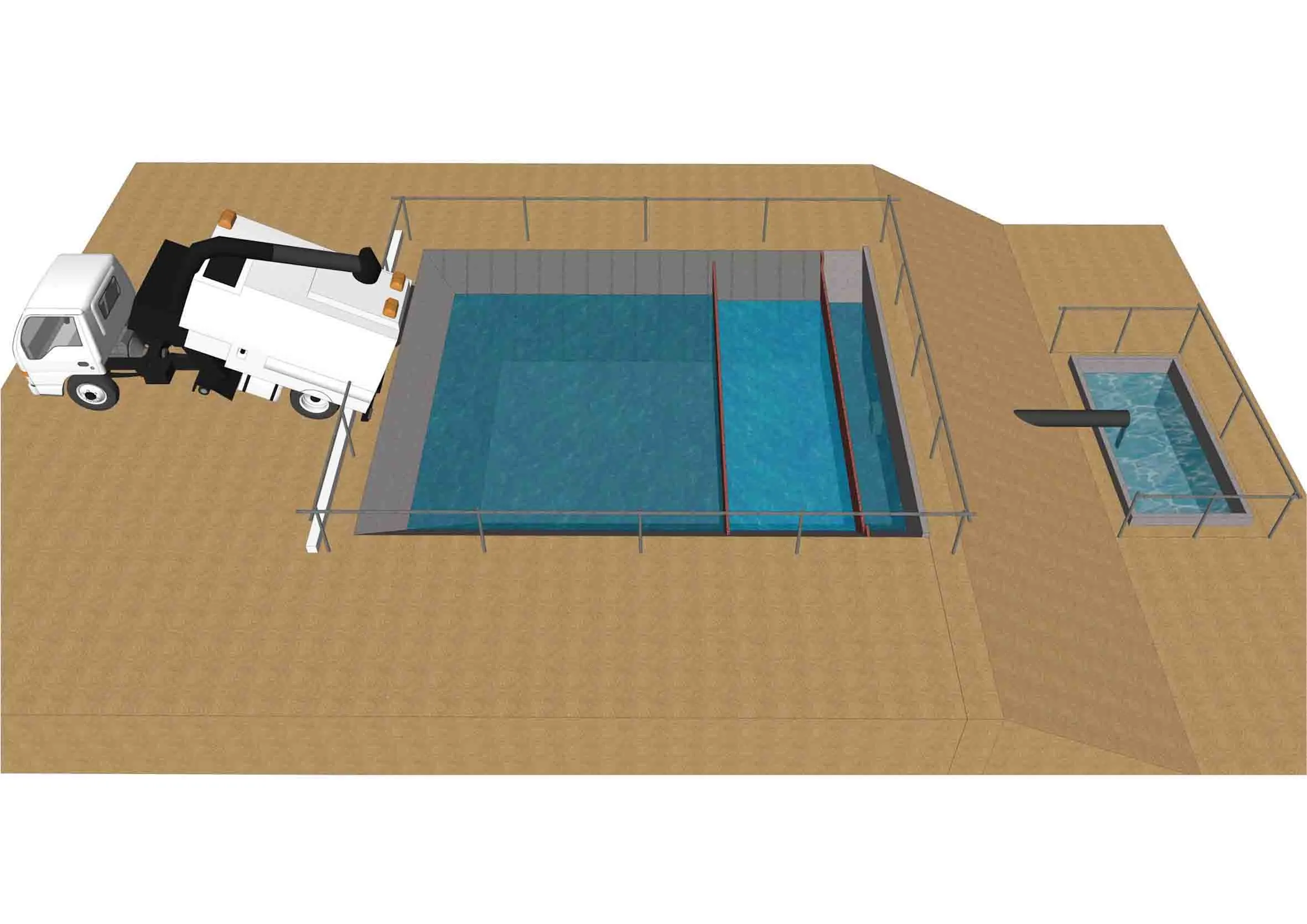

In contrast to traditional web truss structures, the new fabric buildings utilise Legacy’s rigid frame engineering concept, said to allow a high level of design flexibility. The buildings measure 31.7metres by 37metres, and both feature a 2.5metre high concrete wall. In addition to housing a large salt supply, the Legacy structures were specially built to accommodate a fully contained brine-making area, de-icing chemical storage, and a pre-wash pit for cleaning salt trucks prior to entering the maintenance building’s wash bay.

INDOT says it is looking ahead to more innovative design initiatives aimed at additional cost savings, and are keen to grow its list of unit maintenance facilities that have received the Salt Institute’s Excellence in Storage Award for environmentally sensitive salt storage.