Germany plans to spend nearly €19 billion on the construction of a new hydrogen network. The network will extend 9,0404km, although around 60% of this will be for conventional natural gas pipelines that will be modified to handle hydrogen instead.

The project is being managed by the Bundesnetzagentur (BNetzA), Germany’s regulatory office for electricity, gas, telecommunications, post and railway markets. It is a federal agency of the Federal Ministry for Economic Affairs and Climate Action and headquartered in Bonn.

According to BNetzA, “The aim of the National Hydrogen Strategy is the market ramp-up of hydrogen. To achieve this aim, measures are being taken to ensure the availability of sufficient hydrogen and the development of an efficient hydrogen infrastructure.

“The first step in developing a hydrogen infrastructure is planning and setting up a hydrogen core network. The hydrogen core network is to connect what are expected to be Germany's major hydrogen consumption and generation regions – central locations such as large industrial centres, storage facilities, power plants and import corridors – with each other. The hydrogen core network is to comprise key hydrogen infrastructure to be put into operation by 2032.

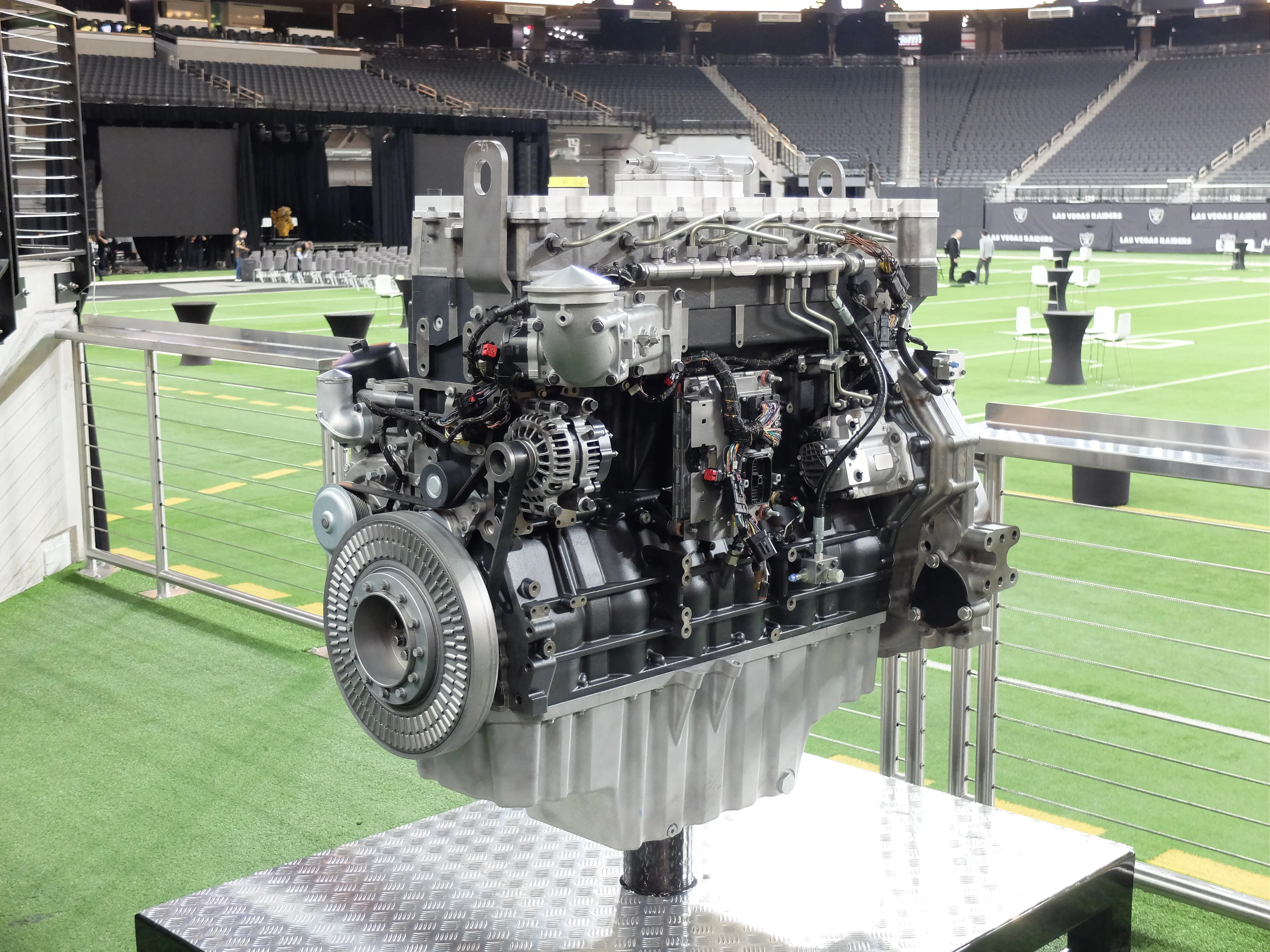

Hydrogen will become a crucial fuel for industrial purposes. Vehicle and off-highway construction machinery manufacturers are already developing engines able to run on hydrogen. More importantly, the use of hydrogen in industrial applications such as heating for asphalt plants or in cement and concrete production could yield massive reductions in CO2 emissions and help reduce the most disastrous effects of climate change.