Cummins and its technology partners have completed their joint project to develop hydrogen-fuelled internal combustion engine technology for on-road vehicles. The technology will also be applicable to heavy equipment for off-highway purposes, including construction machinery.

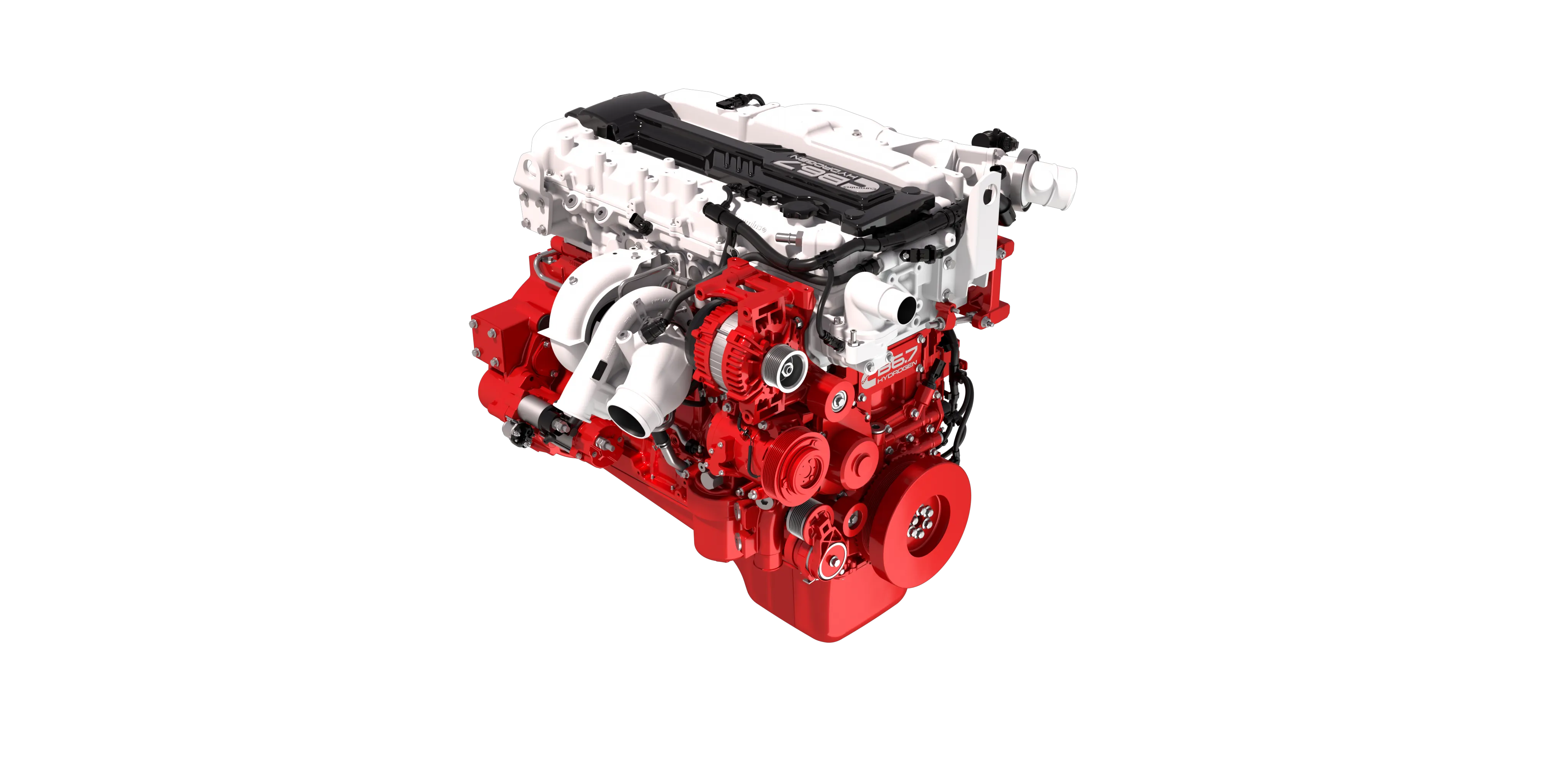

Cummins headed the consortium which also comprised Johnson Matthey, PHINIA and Zircotec. The Project Brunel was to deliver a 6.7litre hydrogen internal combustion engine (H2-ICE) for use in medium-duty trucks and buses. The project was match-funded by UK Government, and facilitated by the Advanced Propulsion Centre UK (APC).

Together, the project partners developed a hydrogen internal combustion engine concept based on Cummins’ proven spark-ignited engine platform. The project has used new hydrogen fuel injection technology from PHINIA, after-treatment catalyst and advanced metals chemistry development from Johnson Matthey, and hydrogen barrier coatings from Zircotec. The team has delivered significant improvements in H2-ICE engine performance and durability.

Jonathan Atkinson, Executive Director - Product Strategy at Cummins, said: “Project Brunel highlights the power of collaboration between industry leaders and underscores our ongoing commitment to industry decarbonisation. This project has successfully delivered a viable, familiar power option that meets the operating requirements of today’s commercial vehicles - with zero-carbon fuel, and without the need for a complete vehicle redesign. This is a major achievement for Cummins Darlington, and for the UK’s hydrogen technology leadership. We hope the Government recognises this technology’s potential for commercial vehicles beyond 2035 and 2040, to align regulation with other major global markets.”

Matt Shillito, Senior Project Delivery Lead, the Advanced Propulsion Centre UK (APC), said: “Project Brunel has built on the UK’s already world-leading capability in manufacturing engines and associated systems and has shown how this industry sector and the skilled jobs it supports can evolve to provide new solutions using zero-carbon hydrogen fuel. These products together can help accelerate the decarbonisation journey for vehicle operators.

The project investment from the Department for Business and Trade, delivered through the APC, offered a significant opportunity for the UK to create a high-value H2-ICE manufacturing base and a competitive export business. It has been a pleasure working with the consortium on this project, and we look forward to seeing success in the market for all the partners.”

Tauseef Salma, Chief Technology Officer - Clean Air at Johnson Matthey, said: “H2-ICE is a ready to go, near net zero option in the powertrain toolbox to decarbonise the medium and heavy-duty transport sector. JM proudly pioneered automotive emissions control catalysts and has since invested decades of research and development into minimising harmful pollutants that enter the atmosphere. We are proud to have applied this expertise in Project Brunel which demonstrates how the industry can come together to increase the commercial viability of H2-ICE technology."

Dr. Simon Godwin, Vice President of Government Affairs at PHINIA, commented: “Project Brunel has enabled us to accelerate the development of hydrogen injectors by cooperation with industry peers and by leveraging our own investment with government support. The project strengthens the UK ecosystem for hydrogen combustion engines and promotes the development and manufacture of this important decarbonisation technology in the UK.”

Cummins recently invested more than £13 million in a new Powertrain Test Facility at its Darlington Campus, which expands the company’s test capabilities to include full powertrains powered by advanced diesel, natural gas, hydrogen and battery electric technologies for multiple industries.