Oerlikon has launched a new hybrid electric drivetrain for wheeled loaders that is predicted to reduce fuel consumption by up to 30%. The hybrid package is a complete electric driveline system. It starts with engine partner Cummins supplying its 12litre QSG engine that meets Tier 4 Final emissions regulations.

January 6, 2017

Read time: 2 mins

The hybrid package is a complete electric driveline system. It starts with engine partner

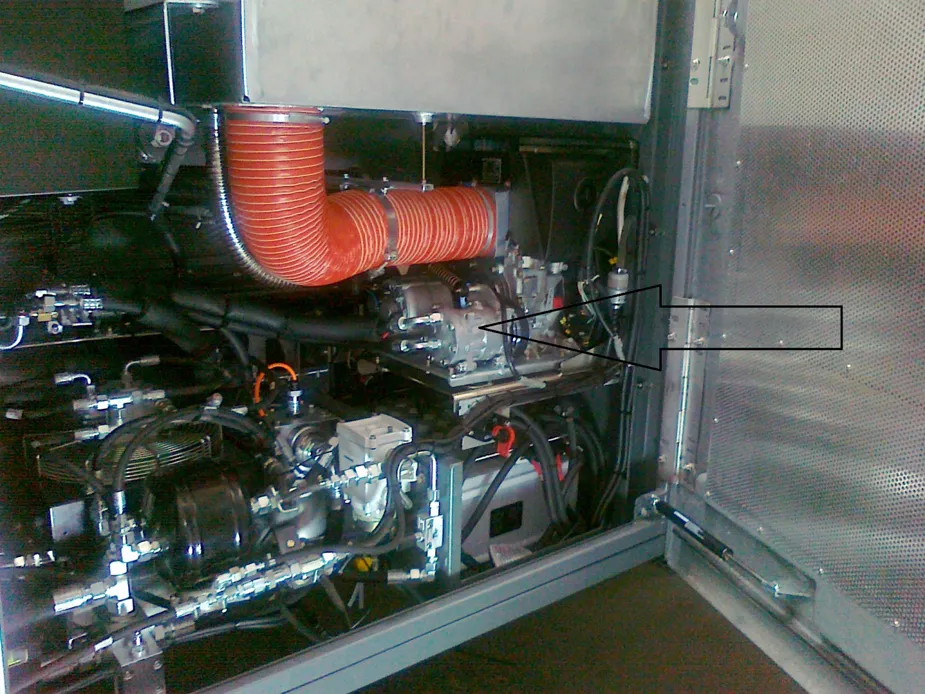

The engine carries a reluctance-type motor/generator to produce electrical power, which drives the wheels through individual high-power electric wheel motors.

The oil-cooled 65kW switch reluctance wheel motors contain a single-speed gearbox, creating a 100:1 reduction to transfer electrical power into high torque wheel drive. Each wheel motor gearbox contains park and service brakes, and allows regenerative energy recovery under braking – Ideal for repetitive duties performed by wheeled loaders. A bank of ultra-capacitors is used to store and release electrical energy on-demand.

While the system is still in the development stages, Cummins engineers expect the QSG engine to operate as a constant speed engine, in a sweet spot of around 1,200rpm while delivering 400hp.

The hybrid system, which was unveiled at Conexpo 2014 this week, is currently being installed in the LW900K, a 30tonne class XCMG wheeled loader. It is expected to be unveiled as a working prototype in November 2014 at Bauma China.

Oerlikon expects the hybrid system to be lighter in overall weight to conventional driveline components. A further benefit of the system, said the company, is that the compact wheel motor design used by the hybrid driveline could eventually lead to the development of independent suspension for wheeled loaders.

%$Linker: