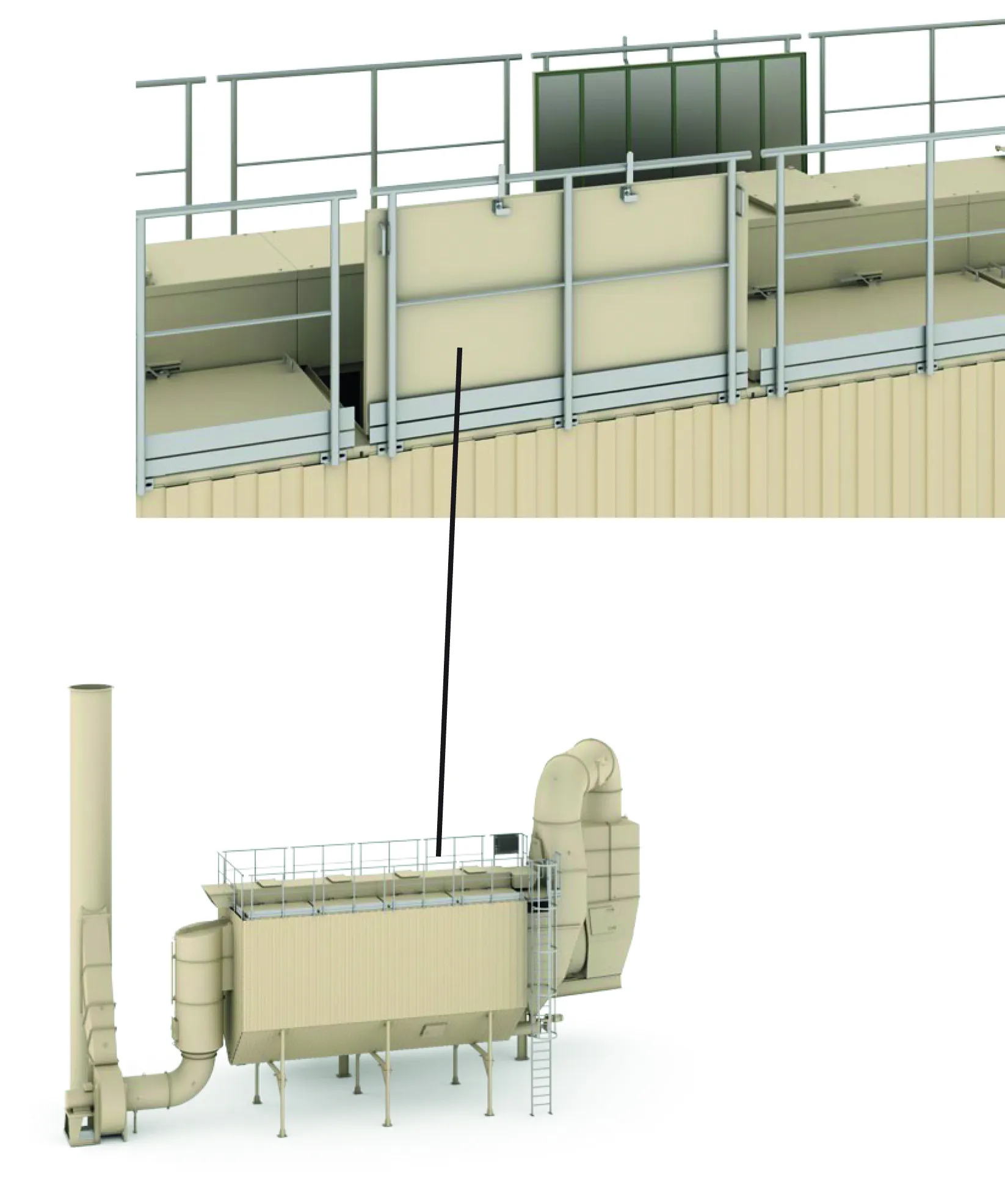

Ammann’s new asphalt mixing plant filter - AFA 3018 – on show at bauma 2013 is said to provide high separation accuracy, improved flow distribution and is virtually maintenance-free. State-of-the-art CFD simulation is said by the Swiss company to be behind the increase in flow distribution quality. As a result, filter bags are said to be filled more evenly, which improves their efficiency and useful life. Key to high separation accuracy of the fine and coarse filler is what is described as a new and innovat

February 6, 2013

Read time: 2 mins

State-of-the-art CFD simulation is said by the Swiss company to be behind the increase in flow distribution quality. As a result, filter bags are said to be filled more evenly, which improves their efficiency and useful life.

Key to high separation accuracy of the fine and coarse filler is what is described as a new and innovative pre-screener. The heightened degree of separation also, in turn, improves the quality of reclaimed filler.

The new heat package for the AFA 3018 is said to ensure that the temperature loss in the filter never exceeds 10°C due to the presence of pre-heated cleaning air. The claimed ‘intelligent’ heating process is said to remove adherent filler gently and thoroughly from the Ammatex filter bags. Ammann says the Ammatex filter bags are high temperature resistant and do not require a fresh air flap.

Meanwhile, the Rotor-Step cleaning system for the AFA 3018 is said to be robust, easy to maintain and highly durable thanks to reliance on a small number of moving parts. The optimised flushing method is also said by Ammann to save energy as it works without the need for an additional fan or compressed air.

Ammann says all the AFA3018 filter’s replacement parts and maintenance points are easily accessible.

Stand: F11.1109

%$Linker: