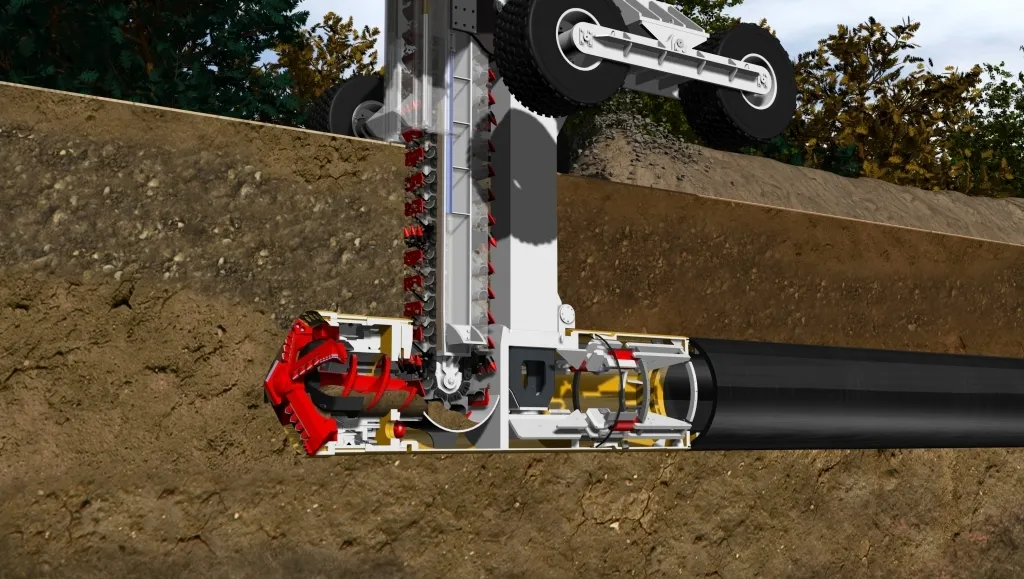

Herrenknecht’s innovative Pipe Express system offers a novel semi-trenchless method of installing pipelines effectively and efficiently. The system can cope with pipe diameters from 800mm-1.5m and is a combination of tunnel boring machine (TBM) technology with a chain trencher. The TBM unit, trencher and buggy run on the surface, along with an operating vehicle and the equipment is modular and said to be easy to transport and set-up on site. Silke Rockenstein is in charge of corporate communications at the

February 6, 2013

Read time: 2 mins

The Pipe Express system is controlled remotely from the operating vehicle and there is no need to dig any trenches in advance, reducing personnel requirements and increasing safety. “You can lay pipe directly into the ground,” she said. “With the trench cutter we transport the soil directly to the surface and it’s an economical and efficient method for the pipe laying industry.”

The system can be used in land with a comparatively high water table and in unstable ground, giving it greater versatility than conventional equipment. The surrounding soil structure has minimal disturbance when this equipment is used, while there is no need for complex groundwater lowering. A key feature of this novel approach is the reduced space requirement in comparison with conventional methods using excavators and dump trucks followed by pipelayers, cutting the width required by 70%. This will also reduce installation costs as contractors will have to pay lower land use rates while installing piping. The reduced space requirement is a key point as it will allow pipes to be laid alongside highways for example, while traffic continues to flow. “We think we can lay pipe alongside a motorway for oil, gas, electricity or other utilities,” Rockenstein said.

Stand: C3.415/514

%$Linker: