In a bid to reduce costs, increase pavement quality, and minimise travel delays caused by road construction, the US Federal Highway Administration (FHWA), the American Association of State Highway and Transportation Officials (AASHTO), and the Transportation Research Board (TRB) are to help agencies implement a tool that allows contractors to identify concrete pavement surface irregularities during construction.

Real-time pavement smoothness has been selected for guided implementation under the second Stra

April 23, 2014

Read time: 2 mins

In a bid to reduce costs, increase pavement quality, and minimise travel delays caused by road construction, the US 2410 Federal Highway Administration (FHWA), the 3510 American Association of State Highway and Transportation Officials (AASHTO), and the 2774 Transportation Research Board (TRB) are to help agencies implement a tool that allows contractors to identify concrete pavement surface irregularities during construction.

Real-time pavement smoothness has been selected for guided implementation under the second Strategic Highway Research Program (SHRP2). In May 2014, SHRP2 will begin accepting applications from state departments of transportation (DOTs) who wish to use real-time concrete pavement smoothness to speed up construction and increase quality on their projects.

SHRP2 is an initiative committed to delivering solutions that address growing congestion and aging infrastructure while increasing roadway and construction safety. During typical construction, contractors must wait for concrete pavement to gain adequate strength before evaluating smoothness, which can result in costly penalties and corrective grinding to meet requirements. By monitoring the smoothness of freshly placed concrete, contractors can make timely adjustments to improve operations, increase quality control, and deliver pavements faster.

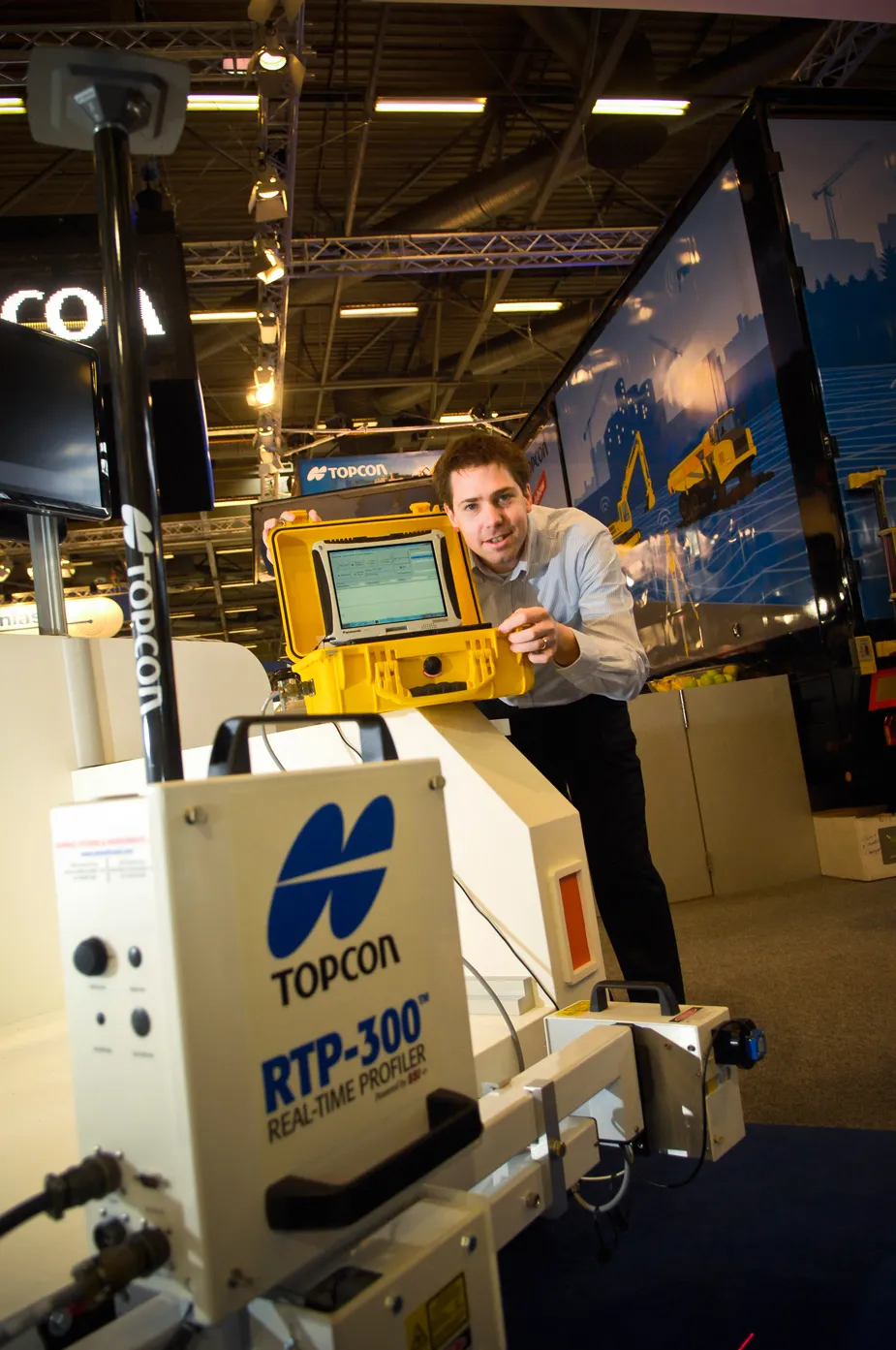

Two devices measuring real-time pavement smoothness will be available for implementation assistance—the218 Gomaco Smoothness Indicator (GMI) and the Ames Engineering Real Time Profiler (RTP). These products were selected for implementation after research and evaluation performed by pavement engineering firm The 5943 Transtec Group under SHRP2.

Principal Investigators Dr Robert O. Rasmussen, Steven M. Karamihas and Gary J. Fick evaluated the devices for practicality and accuracy during pavement projects in Georgia, Texas, Arkansas, Michigan, and New York. You can access the full results of this study—including guidelines for implementation—at TRB online.

State DOTs can apply to participate in the SHRP2 effort to familiarise agencies and associated contractors with the selected real-time pavement smoothness devices. The program aims to provide participating agencies with approximately $60,000 worth of equipment rental, training, and technical support.

Agencies interested in participating must apply online during the application period extending from 30 May – 27 June 2014. To learn more, %$Linker:2 External <?xml version="1.0" encoding="utf-16"?><dictionary /> 0 0 0 oLinkExternal click here http://www.fhwa.dot.gov/goshrp2/ImplementationAssistance false http://www.fhwa.dot.gov/goshrp2/ImplementationAssistance false false %>

Real-time pavement smoothness has been selected for guided implementation under the second Strategic Highway Research Program (SHRP2). In May 2014, SHRP2 will begin accepting applications from state departments of transportation (DOTs) who wish to use real-time concrete pavement smoothness to speed up construction and increase quality on their projects.

SHRP2 is an initiative committed to delivering solutions that address growing congestion and aging infrastructure while increasing roadway and construction safety. During typical construction, contractors must wait for concrete pavement to gain adequate strength before evaluating smoothness, which can result in costly penalties and corrective grinding to meet requirements. By monitoring the smoothness of freshly placed concrete, contractors can make timely adjustments to improve operations, increase quality control, and deliver pavements faster.

Two devices measuring real-time pavement smoothness will be available for implementation assistance—the

Principal Investigators Dr Robert O. Rasmussen, Steven M. Karamihas and Gary J. Fick evaluated the devices for practicality and accuracy during pavement projects in Georgia, Texas, Arkansas, Michigan, and New York. You can access the full results of this study—including guidelines for implementation—at TRB online.

State DOTs can apply to participate in the SHRP2 effort to familiarise agencies and associated contractors with the selected real-time pavement smoothness devices. The program aims to provide participating agencies with approximately $60,000 worth of equipment rental, training, and technical support.

Agencies interested in participating must apply online during the application period extending from 30 May – 27 June 2014. To learn more, %$Linker: