HAZEMAG has realised an intelligent, efficient, compact secondary crushing preparation plant with a minimised overall height for the production of 1,500tonnes/hour of lignite following an order last year from P.T Indonesia Pratama, Indonesia. It was the customer’s wish to get an intelligent crushing solution and a low overall height of the preparation plant. HAZEMAG combined a roller screen with the field-tested feeder breaker HFB 0714, thus offering screening and crushing in one unit, which has dimensions

January 6, 2017

Read time: 2 mins

It was the customer’s wish to get an intelligent crushing solution and a low overall height of the preparation plant.

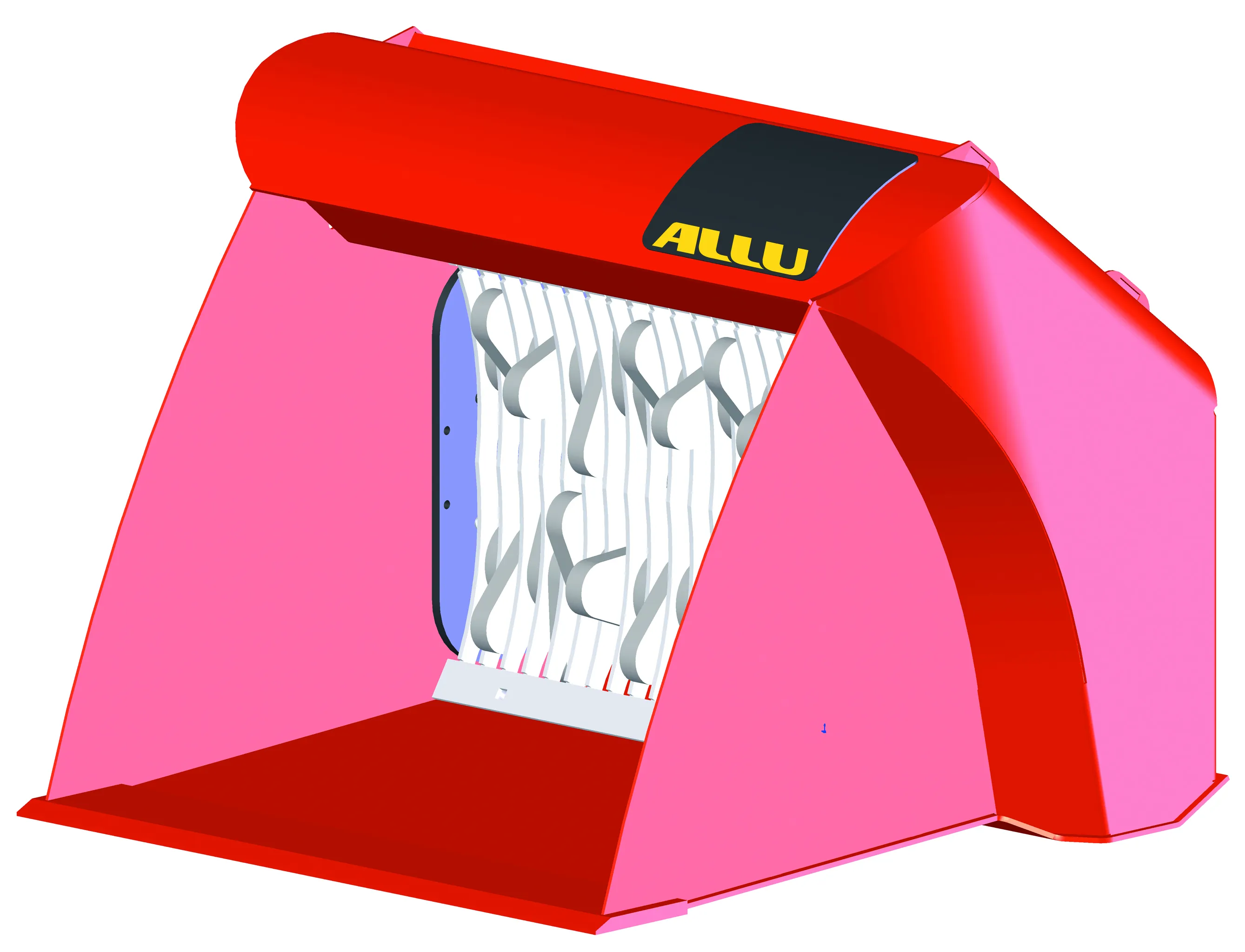

HAZEMAG combined a roller screen with the field-tested feeder breaker HFB 0714, thus offering screening and crushing in one unit, which has dimensions of only 5.4m wide, 3.3m high and 9.7m deep.

A HAZEMAG roller screen is connected upstream of the crushing machine, which is a horizontally arranged crusher roll, and this offers a considerable reduction of the crusher’s construction size and the motor power rating. Due to the screening process any unnecessary material crushing is prevented although different throughput rates as well as end product sizes are achievable.

The screening surface of the roller screen has a width of 2,200mm and a length of 4,200mm and the opening width is 55mm.

Stand: B2.319/414

%$Linker: