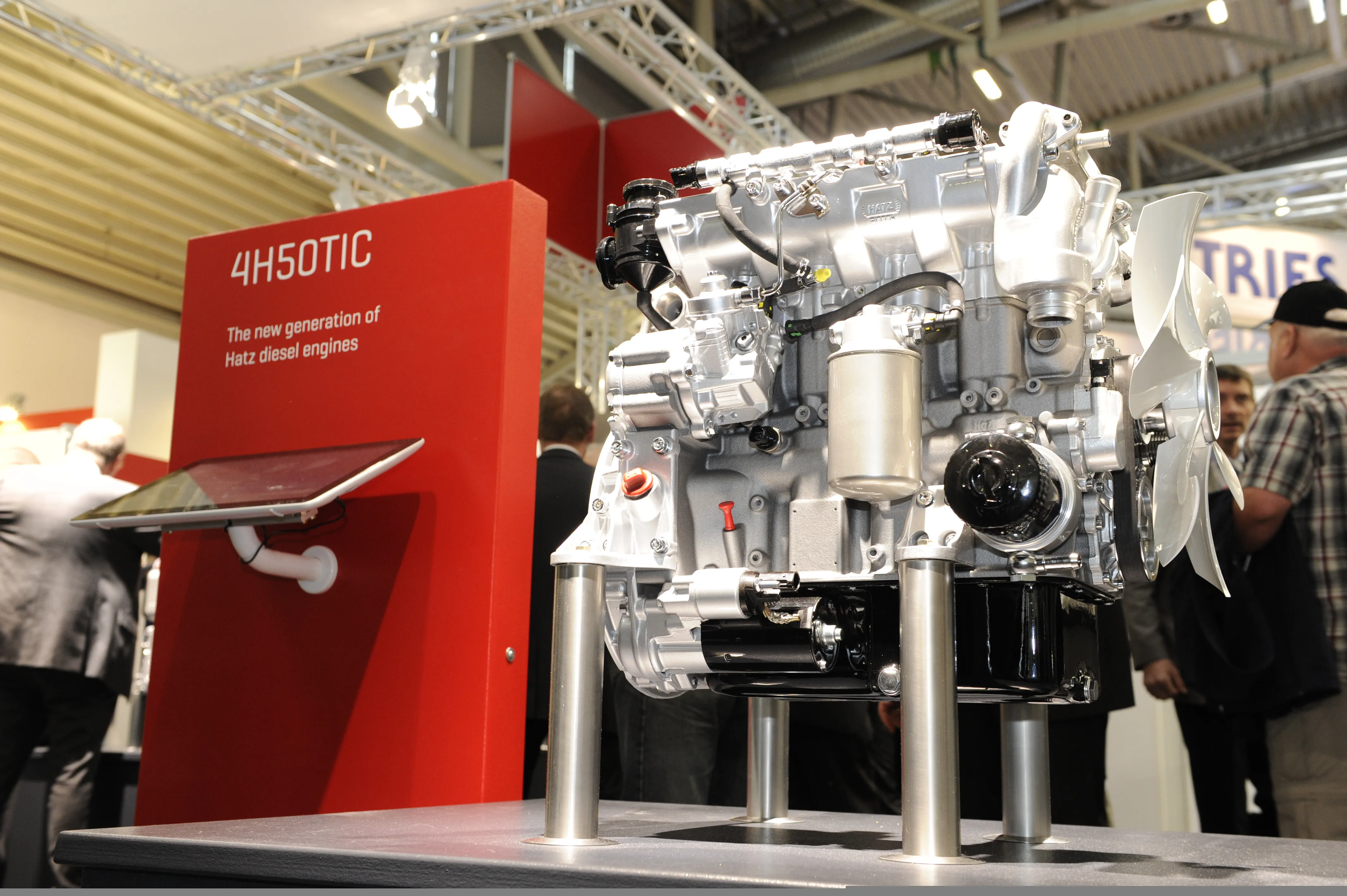

Hatz has boosted diesel engine efficiency with an all-new four-cylinder 2litre platform that combines low weight with low fuel consumption and meets Tier 4 Final/Stage IV emissions regulations without the need for a DPF.

Called the 4H50TIC, the new engine uses two-valve cylinder head design to cut frictional losses, while opting for lower injection pressures of 1,800bar to contribute towards improved fuel efficiency.

January 6, 2017

Read time: 2 mins

Called the 4H50TIC, the new engine uses two-valve cylinder head design to cut frictional losses, while opting for lower injection pressures of 1,800bar to contribute towards improved fuel efficiency.

“Every moving part absorbs power, so with fewer components we can improve efficiency,” said Bernhard Richter-Schutzeneder, Hatz Diesel’s head of marketing. “As a result, we can deliver specific fuel consumption as low as 210g/kW/hour with this engine.”

Using a DOC and cooled EGR – the EGR valve has been deliberately positioned so it is less susceptible to failure from light duty cycles and excessive heat – Hatz said the 4H50TIC does not need low ash engine oils and, in some applications, could expect service intervals to be extended from 500 to 1,000 hours.

Engine design also affords two locations for starter motor mounting – simplifying installation and servicing requirements in compact plant and equipment.

Stand: A4, 423/528

View more videosView more stories