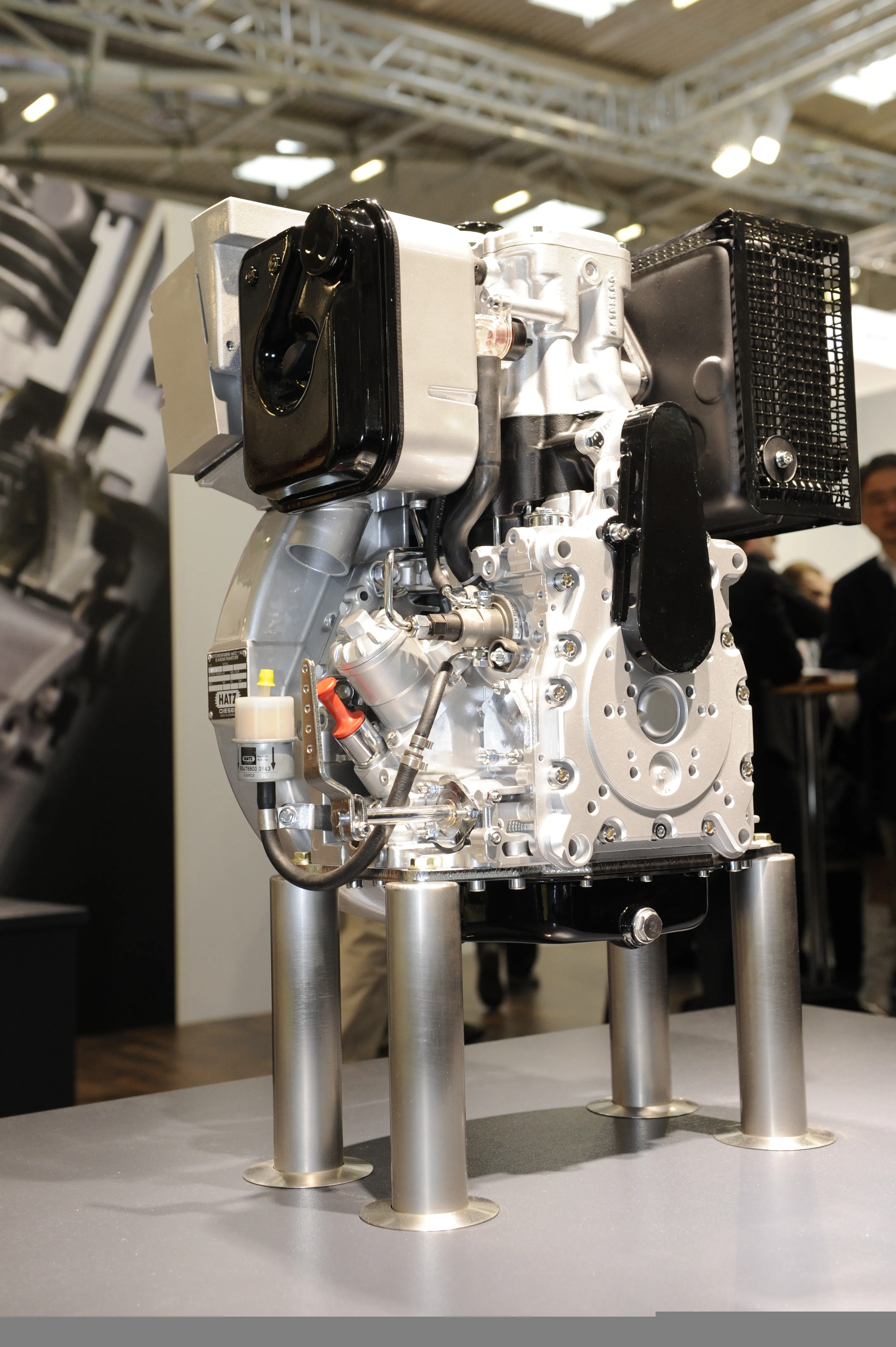

Hatz’s Diesel’s 1D81 Hydro concept has been developed to offer a low noise level solution for applications using single-cylinder diesel engines. Still at prototype stage, the 667cc and 772cc capacity single-cylinder engine is a new variant of an existing Hatz engine design. As such, it uses common components from the Hatz range, but it differs with an all-new cylinder block and cylinder head design that includes a water jacket, allowing liquid cooling to be introduced.

January 6, 2017

Read time: 2 mins

Still at prototype stage, the 667cc and 772cc capacity single-cylinder engine is a new variant of an existing Hatz engine design. As such, it uses common components from the Hatz range, but it differs with an all-new cylinder block and cylinder head design that includes a water jacket, allowing liquid cooling to be introduced.

Cleverly, there are no coolant hoses on the engine – the combined header tank and radiator pack is incorporated into the engine’s assembly, with redirected airflow from the engine’s flywheel being passed through the radiator core.

“We have reached a point in engine development where we cannot make our basic air-cooled engines any quieter,” said Bernhard Richter-Schutzeneder, head of marketing for Hatz Diesel. “Using water-cooling affords that additional level of noise suppression, but it brings additional advantages too.

“We can now extract more power – typically, up to 20% more than the air-cooled equivalent,” he said. “Engine temperature is kept at a constant 85 degrees C, which helps us to increasing engine life and extend service intervals.”

Stand: A4, 423/528

View more videosView more stories