Hamm continues to develop its sophisticated soil compactor range with the addition of models aimed at the 11-16tonne weight classes. These are powered by Tier 4 Interim/Stage IIIB compliant diesels and share the same design concept as well as features and many components with the existing 18-15tonne rollers. The high compaction performance and unobstructed sight lines from the cab of the larger machines have also been carried over into the smaller units. The H11i, H13i and H16i compactors have 2.14m wide d

February 13, 2013

Read time: 3 mins

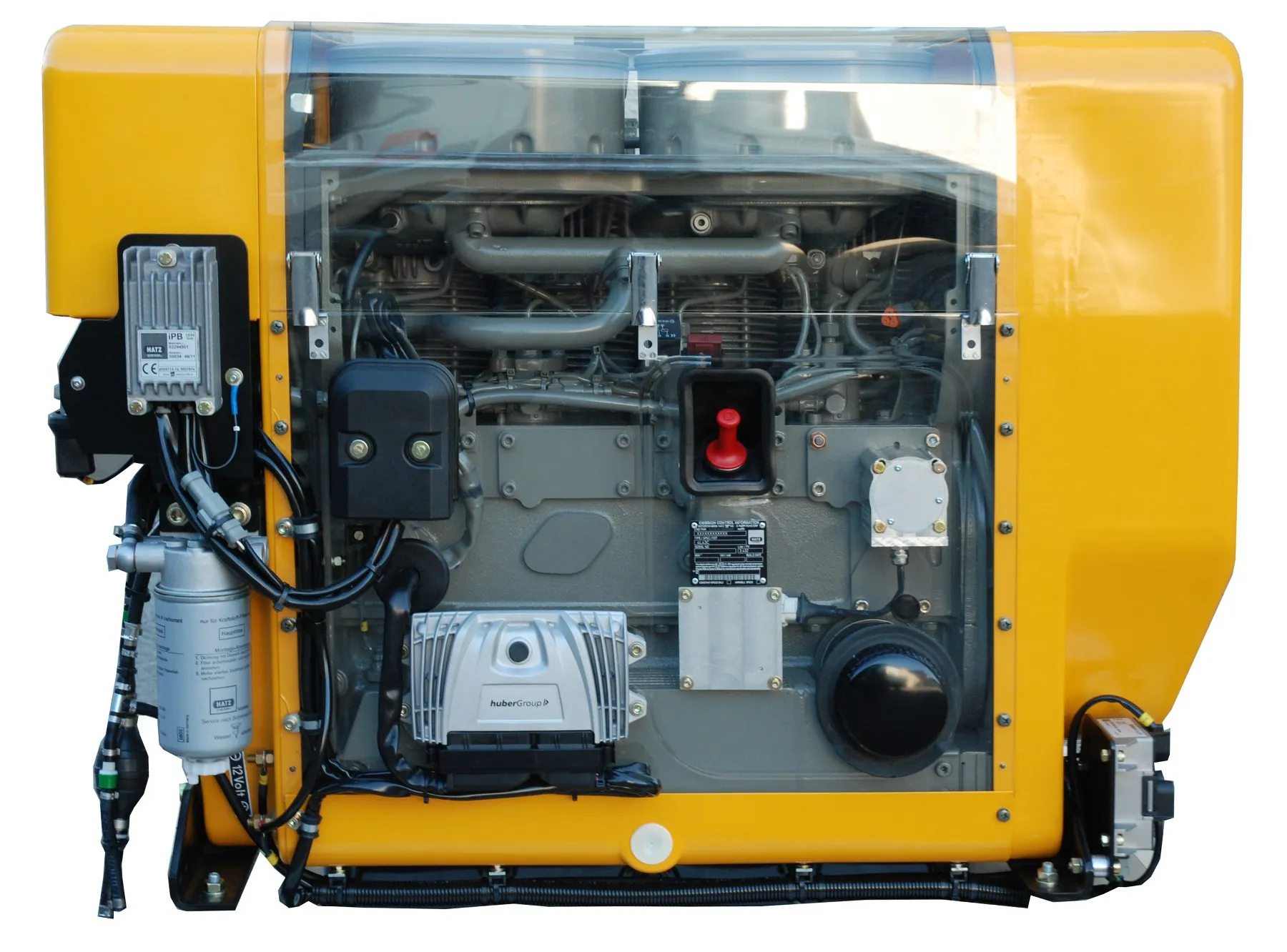

As with the large compactors of the H series, all service points and batteries are also located on one side with the smaller models. The innovative air filter is said to be simple to clean and replace. The new series also comes as standard with a secure storage space under the engine cover in which to keep a toolbox for example. Hamm also offers the compactors with optional low-energy, long-lasting LED working lights on the cab as well as a main headlight with low beam and additional full beam. Reversing cameras are also available as an additional safety feature, while a display allows the driver to check for obstructions behind the roller. These cameras are available now as an optional extra for all H series compactors and can also be retrofitted to all existing machines.

Stand: F10.1011/1012

%$Linker: