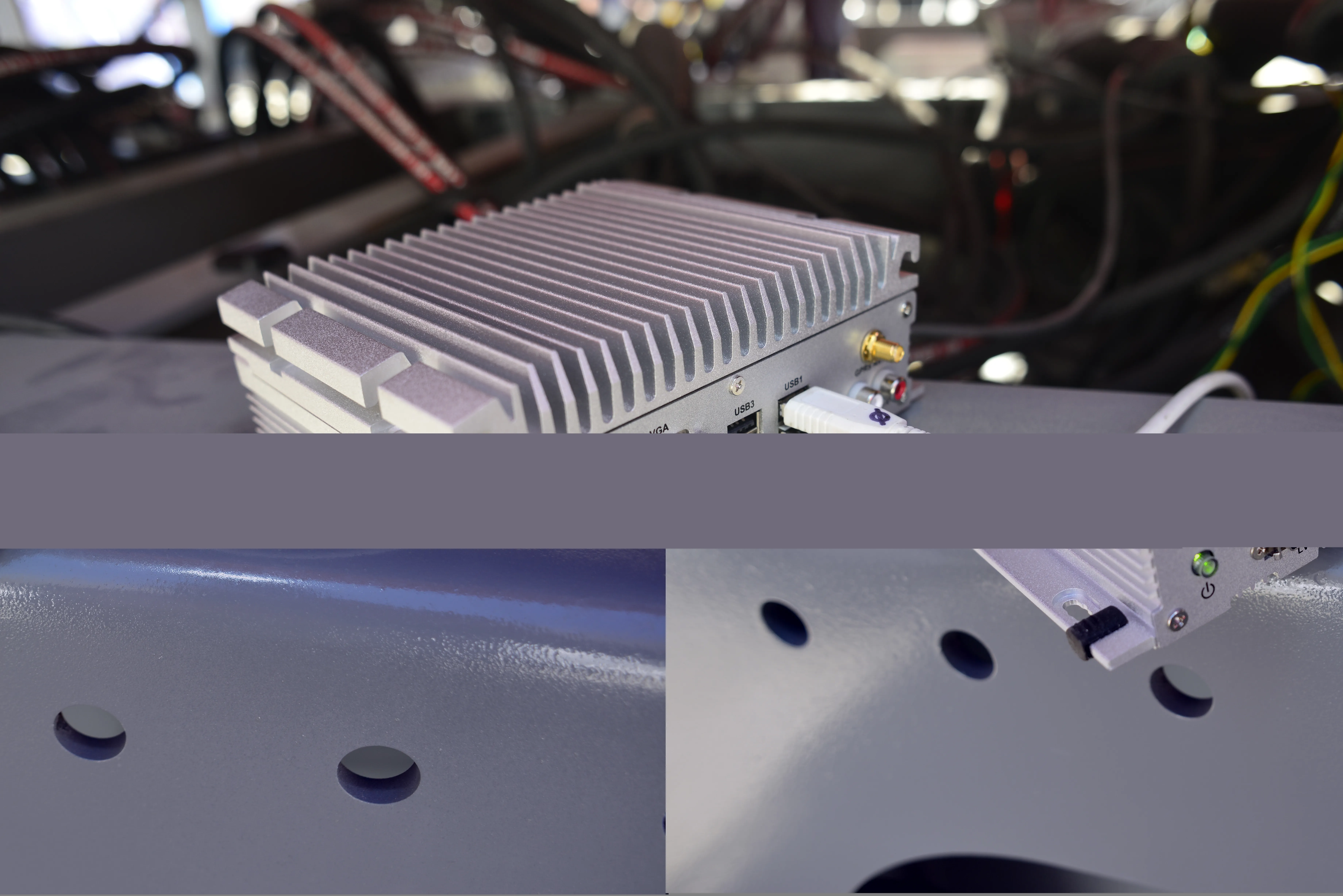

A major launch from Guntert & Zimmermann is of its sophisticated equipment guidance and operation network (EGON), an advanced Plus+1 operator control system. The package is said to incorporate user friendly operator features and state of the art network controllers. The EGON system is similar to the control packages available with rival pavers, and is said to be easy and quick to use.

January 6, 2017

Read time: 2 mins

A major launch from Guntert & Zimmerman is of its sophisticated equipment guidance and operation network (EGON), an advanced Plus+1 operator control system. The package is said to incorporate user friendly operator features and state of the art network controllers. The EGON system is similar to the control packages available with rival pavers, and is said to be easy and quick to use.

Andreas Moser is director of business development – international and he said, “We have communications by GSM. The factory can follow where the paver is and we can also modify the software at a distance.”

Moser explained that the system comes with a new display and provides full communications between the machine control package and the manufacturer. “It will even tell you when to change the oil,” he said.

The EGON system allows ease of use and offers extensive diagnostic capabilities. According to the company, this help to maximise available paving time and overall machine utilisation and minimise down time. The G&Z software engineering team has designed EGON to meet this standard and says that it makes the machine easier to operate, while users can reconfigure, diagnose, and manage equipment more easily. The new EGON package is now being made available on all G&Z slipform paving equipment models.

Andreas Moser is director of business development – international and he said, “We have communications by GSM. The factory can follow where the paver is and we can also modify the software at a distance.”

Moser explained that the system comes with a new display and provides full communications between the machine control package and the manufacturer. “It will even tell you when to change the oil,” he said.

The EGON system allows ease of use and offers extensive diagnostic capabilities. According to the company, this help to maximise available paving time and overall machine utilisation and minimise down time. The G&Z software engineering team has designed EGON to meet this standard and says that it makes the machine easier to operate, while users can reconfigure, diagnose, and manage equipment more easily. The new EGON package is now being made available on all G&Z slipform paving equipment models.

Stand: F10.1013/3

%$Linker: