The new Hi-Stability technology featured in the latest range of Goodyear tyres is said to increase load capacity in off-road applications by up to 25%. The new tyres have been developed to match the power, speed and torque of the industry’s latest machines. Hi-Stability tyres allow higher inflation pressures, increasing the load capacity of the machines to which they are fitted – it is the air that carries the load. A loader that can hold 9tonnes when fitted with conventional tyres at 5bar can carry 12tonne

April 18, 2012

Read time: 1 min

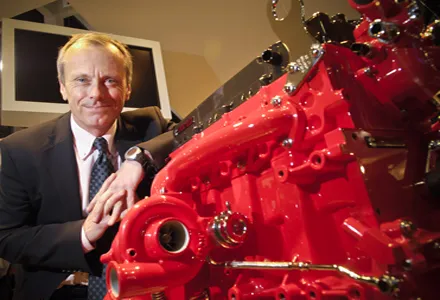

RSSThe new Hi-Stability technology featured in the latest range of 5010 Goodyear tyres is said to increase load capacity in off-road applications by up to 25%.

The new tyres have been developed to match the power, speed and torque of the industry’s latest machines. Hi-Stability tyres allow higher inflation pressures, increasing the load capacity of the machines to which they are fitted – it is the air that carries the load. A loader that can hold 9tonnes when fitted with conventional tyres at 5bar can carry 12tonnes when it has Hi-Stability tyres inflated to 6.5bar, according to Goodyear.

View more stories

View more videos

The new tyres have been developed to match the power, speed and torque of the industry’s latest machines. Hi-Stability tyres allow higher inflation pressures, increasing the load capacity of the machines to which they are fitted – it is the air that carries the load. A loader that can hold 9tonnes when fitted with conventional tyres at 5bar can carry 12tonnes when it has Hi-Stability tyres inflated to 6.5bar, according to Goodyear.

Hall: 5A Stand: F001

RSSView more stories

View more videos