GOMACO’s 4400 slipform paver is designed for versatility, with the ability to handle a wide array of concrete paving and barrier jobs. Customers can select from a wide array of variations to suit specific needs or allow the machine the broadest array of paving capabilities.

March 12, 2012

Read time: 3 mins

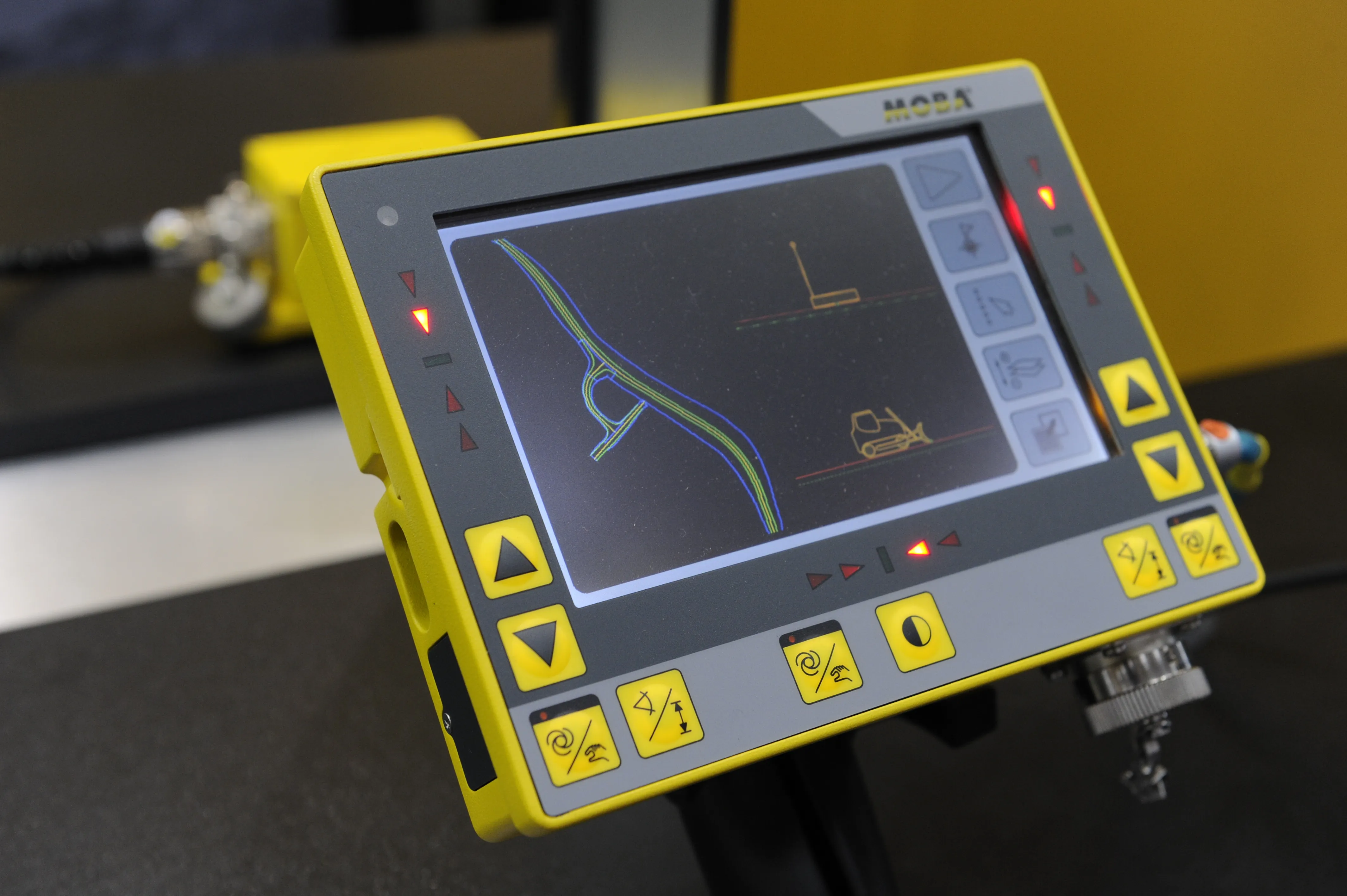

%$Linker: 2 Internal 2 4802 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">RSS</span></span> Road Paving and Recycling false /event-news/intermat-2012/rss/road-paving-and-recycling/ true false %>218 Gomaco’s 4400 slipform paver is designed for versatility, with the ability to handle a wide array of concrete paving and barrier jobs. Customers can select from a wide array of variations to suit specific needs or allow the machine the broadest array of paving capabilities. The machine is available with the latest stringless 3D paving controls from 265 Leica Geosystems, which can help reduce set-up times and offer quick pay pack for the sophisticated package according to the company.

The 4400 is capable of right-side and left-side slipforming and is equipped with GOMACO’s well-proven G+ operating system, which offers multiple language choices. The G+, like GOMACO’s previous digital control systems, also allows easy interfacing with 3D stringless paving technology. This technology has been well proven since the first systems were developed 13 years ago and can be used on various applications such as barrier walls or road paving duties.

The G+ controller offers high definition, multi-coloured bar graph meters to indicate machine deviation, and assist an operator in fine tuning grade and steer performance. Troubleshooting is said to be fast and efficient with advanced system diagnostics. The new G+ control system also coordinates the speed of the hydraulic fan with engine and hydraulic oil temperature. The tractive system on the 4400 features a low speed, allowing for the smooth crawling necessary for a vertical wall. The new G+ speed dial turns to adjust in 1% increments.

The 4400 was designed for economical international shipping with a compact width so that it can be transported in a container. Although the 4400 was built for right-side pour paving, it can also be used for left-side paving jobs. The four-track barrier paver offers symmetrical steering and minimal set-up changes for switching profiles from side-to-side. The novel operator’s platform has a U-shape while the control console slides from side-to-side to accommodate right-side and left-side pour and provides a 360° view of the paving operation. The 4400 is powered by a196 Cummins QSB3.3 diesel rated at 74kW, with a high-capacity cooling package that is also said to provide one of the quietest working platforms in the industry. The quiet operation, along with its vibration damped operator platform, is said to allow a comfortable working environment.

The machine is offered with the new GOMACO Barrier Hook-and-Go mold mounting system to quickly mount barrier molds up to 1m high on either side of the machine. An optional sidemount attachment is available for barrier taller than 1m or existing barrier molds. GOMACO barrier molds are designed for proper vibration and consolidation of material, with the GOMACO-exclusive trailing stainless steel for superior finishing. The barrier machine features the new 4400 series, 406mm diameter auger, with the pitch and speed designed specifically for transporting low-slump concrete. Its four-way hydraulic positioning capability allows the auger to be placed perfectly for concrete receiving and delivery to the mold on either side of the machine.

2 Internal 2 4824 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/intermat-2012/video/ true false %>

The 4400 is capable of right-side and left-side slipforming and is equipped with GOMACO’s well-proven G+ operating system, which offers multiple language choices. The G+, like GOMACO’s previous digital control systems, also allows easy interfacing with 3D stringless paving technology. This technology has been well proven since the first systems were developed 13 years ago and can be used on various applications such as barrier walls or road paving duties.

The G+ controller offers high definition, multi-coloured bar graph meters to indicate machine deviation, and assist an operator in fine tuning grade and steer performance. Troubleshooting is said to be fast and efficient with advanced system diagnostics. The new G+ control system also coordinates the speed of the hydraulic fan with engine and hydraulic oil temperature. The tractive system on the 4400 features a low speed, allowing for the smooth crawling necessary for a vertical wall. The new G+ speed dial turns to adjust in 1% increments.

The 4400 was designed for economical international shipping with a compact width so that it can be transported in a container. Although the 4400 was built for right-side pour paving, it can also be used for left-side paving jobs. The four-track barrier paver offers symmetrical steering and minimal set-up changes for switching profiles from side-to-side. The novel operator’s platform has a U-shape while the control console slides from side-to-side to accommodate right-side and left-side pour and provides a 360° view of the paving operation. The 4400 is powered by a

The machine is offered with the new GOMACO Barrier Hook-and-Go mold mounting system to quickly mount barrier molds up to 1m high on either side of the machine. An optional sidemount attachment is available for barrier taller than 1m or existing barrier molds. GOMACO barrier molds are designed for proper vibration and consolidation of material, with the GOMACO-exclusive trailing stainless steel for superior finishing. The barrier machine features the new 4400 series, 406mm diameter auger, with the pitch and speed designed specifically for transporting low-slump concrete. Its four-way hydraulic positioning capability allows the auger to be placed perfectly for concrete receiving and delivery to the mold on either side of the machine.

%$Linker:

Hall: 5A Stand: J054

%$Linker: