Getech, which says it is among the leaders in the drilling, quarrying and aggregate recycling industries for the water and silt management systems, is introducing its largest model of high performance centrifuge for sludge dewatering in the construction industry. “We have built up extensive knowledge in the last 20 years of processing silts from aggregates, dewatering sludge from the construction of foundations, from quarries, from sand and gravel washing and also recovery of bentonite from weighted mud in

January 6, 2017

Read time: 2 mins

“We have built up extensive knowledge in the last 20 years of processing silts from aggregates, dewatering sludge from the construction of foundations, from quarries, from sand and gravel washing and also recovery of bentonite from weighted mud in vertical drilling applications,” says the company.

“Nowadays we are able to offer solutions for individual applications using the very best technology and our own processing experience.”

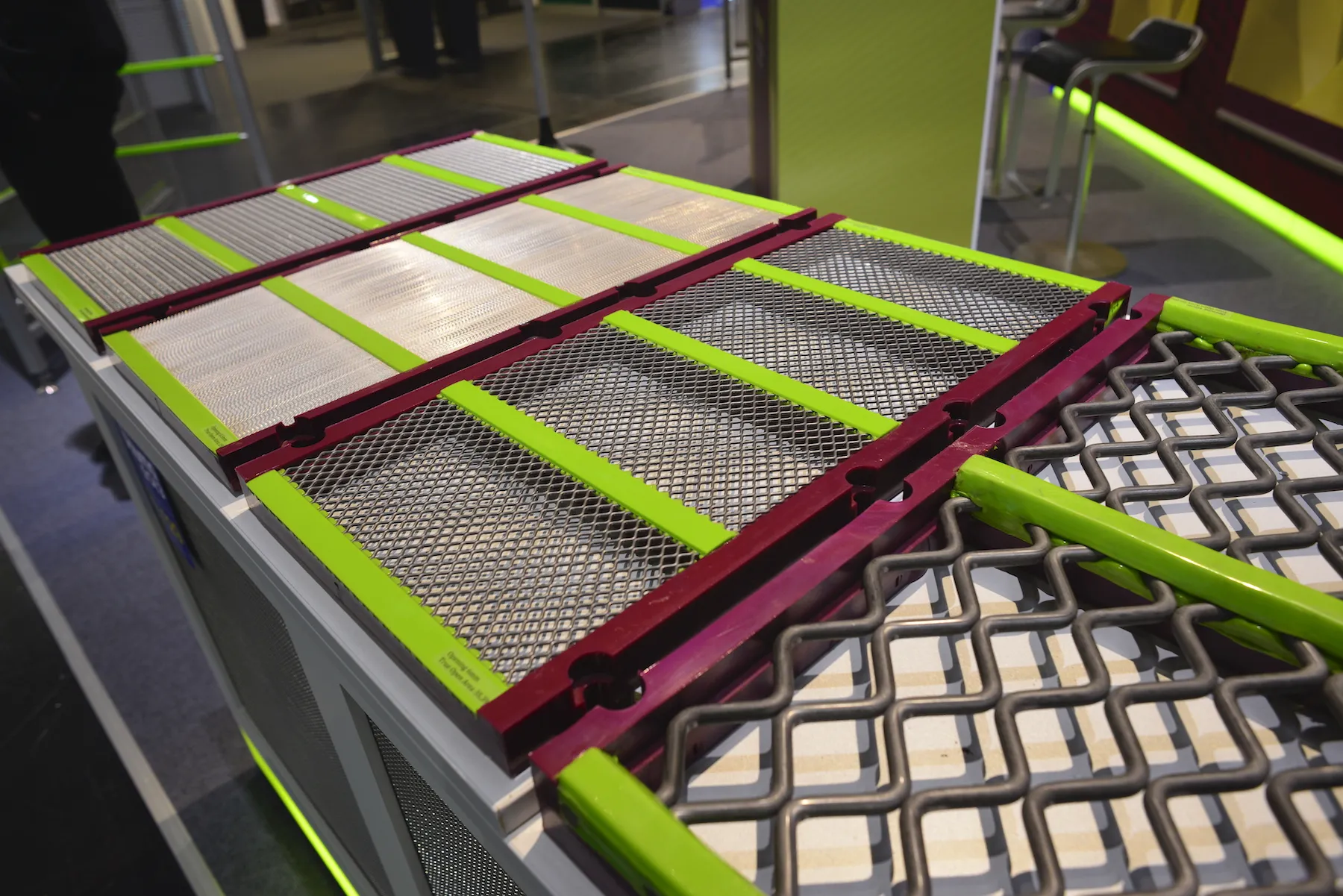

For example, in the construction industry there is an increasing demand on the purity of building materials, and it is necessary to wash and recycle gravel, sand, grit and other building materials. The washing of aggregates is required for many markets and applications, and the finished product needs to meet specifications outlined by the ever-stringent and demanding world markets.

“Where dry screening was accepted in the past, washing and scrubbing are now required to produce a silt-free product. And, at the end of the process there will be dirty water/sludge to dispose of. In the past this dirty water was flown in a rinsing pond where coarse particles are sedimented and a proportion of roughly cleaned water is reused. But the rinsing pond takes up a lot of space as several ponds are necessary to get a well-dewatered sludge. The majority of the water seeps away and cannot be reused, and the sludge has to be removed by an earthmover,” says Getech, which claims there are advantages to dewatering this sludge by use of a centrifuge.

“Dewatered sludge can be transported and used as bulk material; it reduces consumption of fresh water thanks to a high volume of recycled used water; low maintenance, operation and cleaning-effort, and it is environmentally friendly, with no soil pollution,” added Getech.

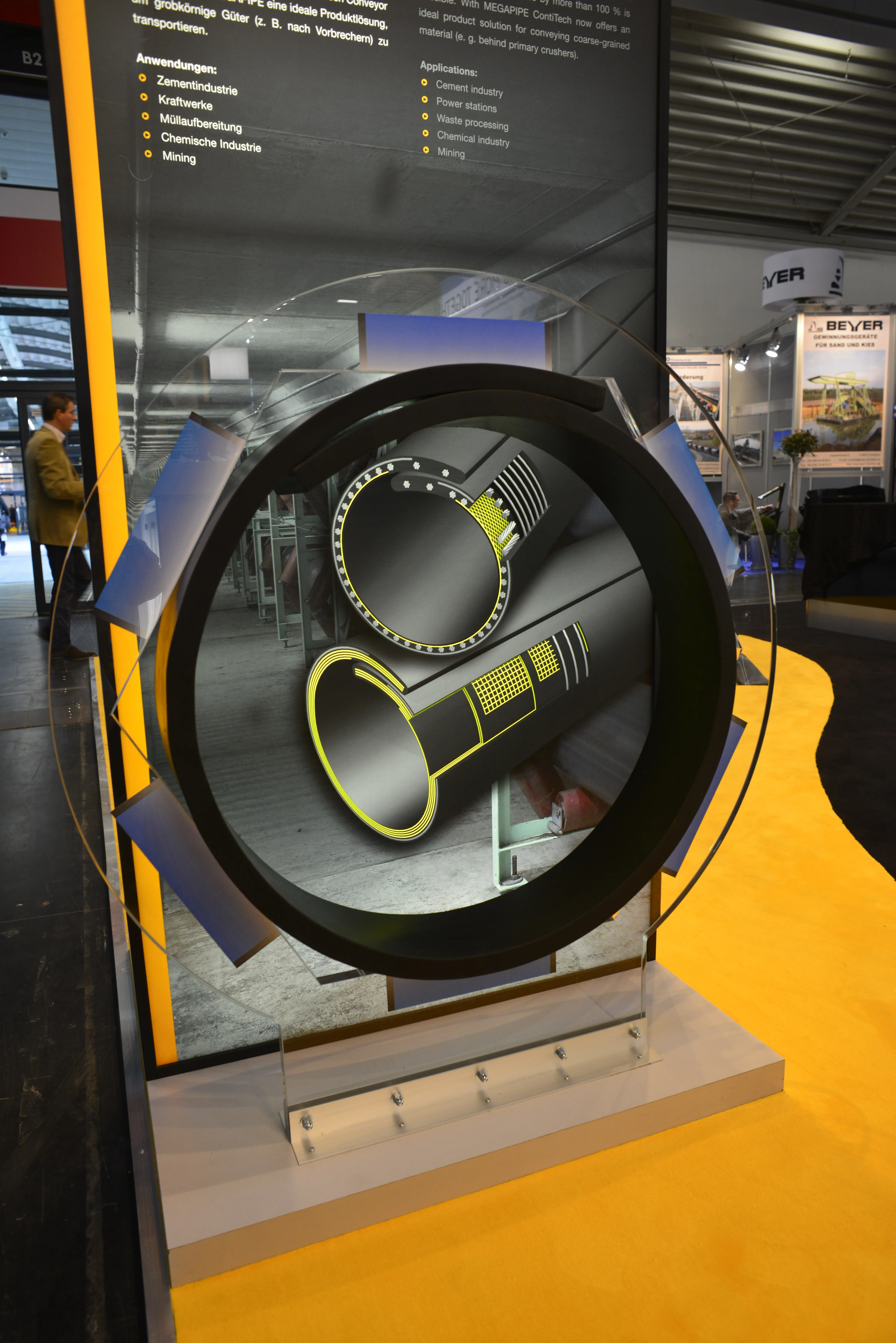

Stand: B2.105B

%$Linker: