In what could help fuel widespread adoption of natural gas-powered (NG) vehicles in the US and globally, GE researchers, in partnership with Chart Industries and scientists at the University of Missouri, have been awarded a programme through Advanced Research Projects Agency for Energy (ARPA-E) to develop an affordable at-home refuelling station that would meet ARPA-E’s target of $500 per station and reduce re-fuelling times from 5-8 hours to less than 1 hour.

July 20, 2012

Read time: 3 mins

In what could help fuel widespread adoption of natural gas-powered (NG) vehicles in the US and globally, 6259 GE researchers, in partnership with Chart Industries and scientists at the University of Missouri, have been awarded a programme through Advanced Research Projects Agency for Energy (ARPA-E) to develop an affordable at-home refuelling station that would meet ARPA-E’s target of $500 per station and reduce re-fuelling times from 5-8 hours to less than 1 hour.

Natural gas prices are at an all-time low and the number of NG vehicles is increasing, but several barriers are preventing greater adoption of this vehicle technology. These include the inconvenience and low availability of refuelling stations and limited driving range of NG vehicles.

Although at-home refuelling stations are sold currently, at around $5,000 they are expensive and require long re-fuelling times. The 5-8 hours required to refuel an NG vehicle often leaves overnight re-fuelling as the only the viable option for vehicle owners. While these barriers can be more easily managed by established fleets, they are not practical for passenger vehicles parked in the driveway or garage at home.

“Since the beginning of the automotive industry, cars and trucks have driven on diesel fuel or unleaded gas,” said Anna Lis Laursen, project leader and chemical engineer at GE Global Research. “But with new technologies to reduce the cost of NG re-fuelling and continued improvements in battery technology, the prospects for vehicles that run on alternative fuels will only grow.

“The goal of our project is to design an at-home refuelling station that is much simpler in design, more cost effective and reduces re-fuelling times to under an hour. By reducing the time and cost of re-fuelling, we can break down the barriers that are preventing more widespread adoption of NG vehicles. If we can meet our cost targets, the price of a home refuelling station would be less than typical appliances in the home such as a dishwasher or stove.”

Today, the number of NG vehicles globally is estimated at around 15 million, with more than 250,000 in the US. Most are fleet vehicles such as buses and delivery trucks, but they include some passenger cars as well. With further improvements in the infrastructure to support NG vehicles, the market penetration could be much higher.

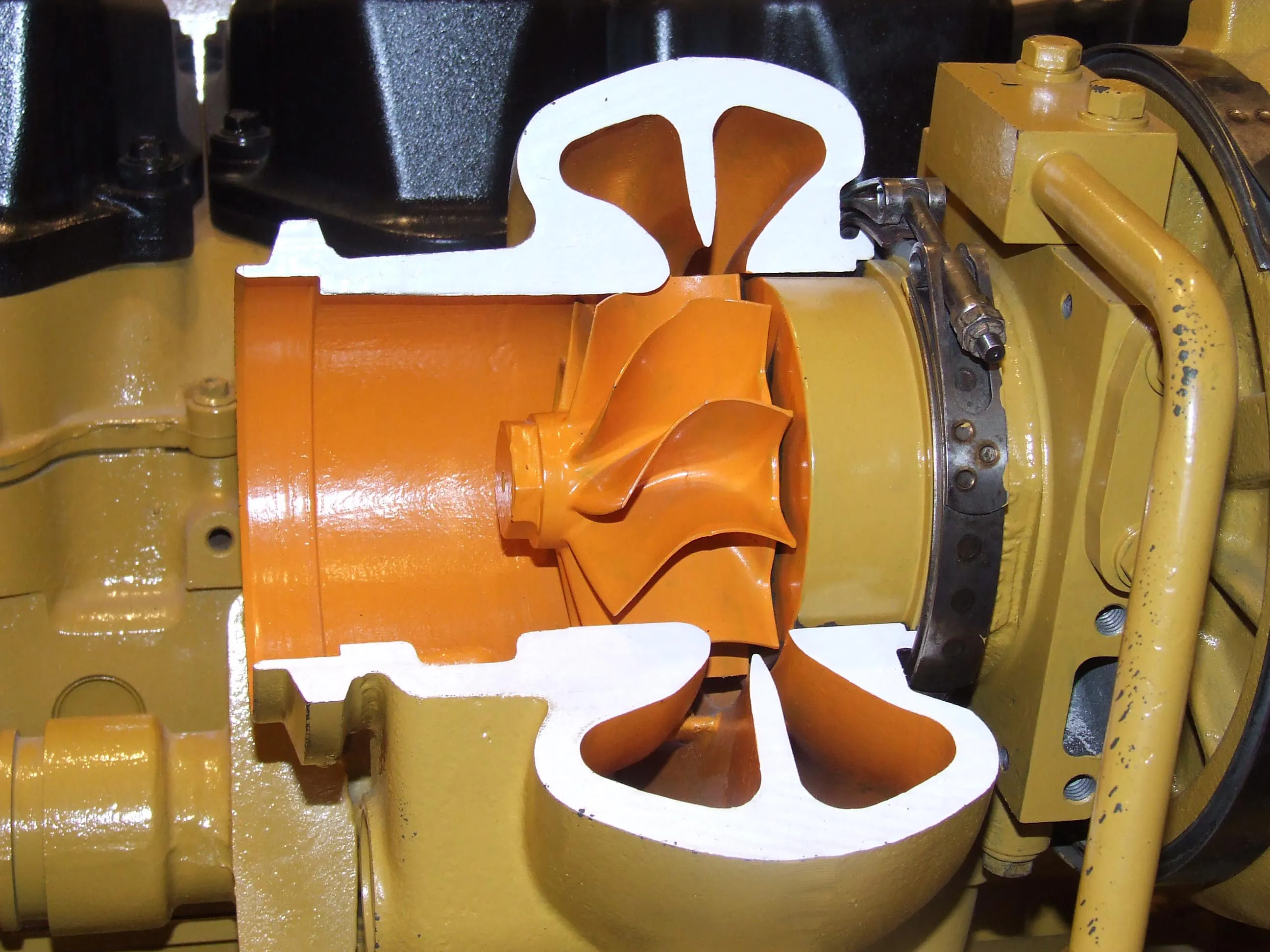

The refueling station design being worked on is fundamentally different from how today’s re-fuelling stations operate. Today’s systems rely on traditional compressor technologies to compress and deliver fuel to a vehicle. The research team from GE, Chart Industries and the University of Missouri will design a system that chills, densifies and transfers compressed natural gas more efficiently. It will be a much simpler design with fewer moving parts, and that will operate quietly and be virtually maintenance-free.

The total cost of the 28-month programme will be around $2.3 million, which will be shared by ARPA-E and GE. As part of the programme, GE researchers will focus on overall system design integration. Chart Industries and University of Missouri will address the detailed engineering, cost and manufacturability of the key system components.

Natural gas prices are at an all-time low and the number of NG vehicles is increasing, but several barriers are preventing greater adoption of this vehicle technology. These include the inconvenience and low availability of refuelling stations and limited driving range of NG vehicles.

Although at-home refuelling stations are sold currently, at around $5,000 they are expensive and require long re-fuelling times. The 5-8 hours required to refuel an NG vehicle often leaves overnight re-fuelling as the only the viable option for vehicle owners. While these barriers can be more easily managed by established fleets, they are not practical for passenger vehicles parked in the driveway or garage at home.

“Since the beginning of the automotive industry, cars and trucks have driven on diesel fuel or unleaded gas,” said Anna Lis Laursen, project leader and chemical engineer at GE Global Research. “But with new technologies to reduce the cost of NG re-fuelling and continued improvements in battery technology, the prospects for vehicles that run on alternative fuels will only grow.

“The goal of our project is to design an at-home refuelling station that is much simpler in design, more cost effective and reduces re-fuelling times to under an hour. By reducing the time and cost of re-fuelling, we can break down the barriers that are preventing more widespread adoption of NG vehicles. If we can meet our cost targets, the price of a home refuelling station would be less than typical appliances in the home such as a dishwasher or stove.”

Today, the number of NG vehicles globally is estimated at around 15 million, with more than 250,000 in the US. Most are fleet vehicles such as buses and delivery trucks, but they include some passenger cars as well. With further improvements in the infrastructure to support NG vehicles, the market penetration could be much higher.

The refueling station design being worked on is fundamentally different from how today’s re-fuelling stations operate. Today’s systems rely on traditional compressor technologies to compress and deliver fuel to a vehicle. The research team from GE, Chart Industries and the University of Missouri will design a system that chills, densifies and transfers compressed natural gas more efficiently. It will be a much simpler design with fewer moving parts, and that will operate quietly and be virtually maintenance-free.

The total cost of the 28-month programme will be around $2.3 million, which will be shared by ARPA-E and GE. As part of the programme, GE researchers will focus on overall system design integration. Chart Industries and University of Missouri will address the detailed engineering, cost and manufacturability of the key system components.