Future vehicles will no longer rely on power from internal combustion engines as the supply of oil dwindles and as climate change issues force a reduction in carbon dioxide emissions. According to a report from IDTechEx, there are three major technological trends for vehicles that are becoming increasingly important. These trends are shaping the development of new vehicles, targeting them at specific customer types and also the applications for these vehicles.

July 2, 2015

Read time: 3 mins

Future vehicles will no longer rely on power from internal combustion engines as the supply of oil dwindles and as climate change issues force a reduction in carbon dioxide emissions. According to a report from IDTechEx, there are three major technological trends for vehicles that are becoming increasingly important. These trends are shaping the development of new vehicles, targeting them at specific customer types and also the applications for these vehicles.

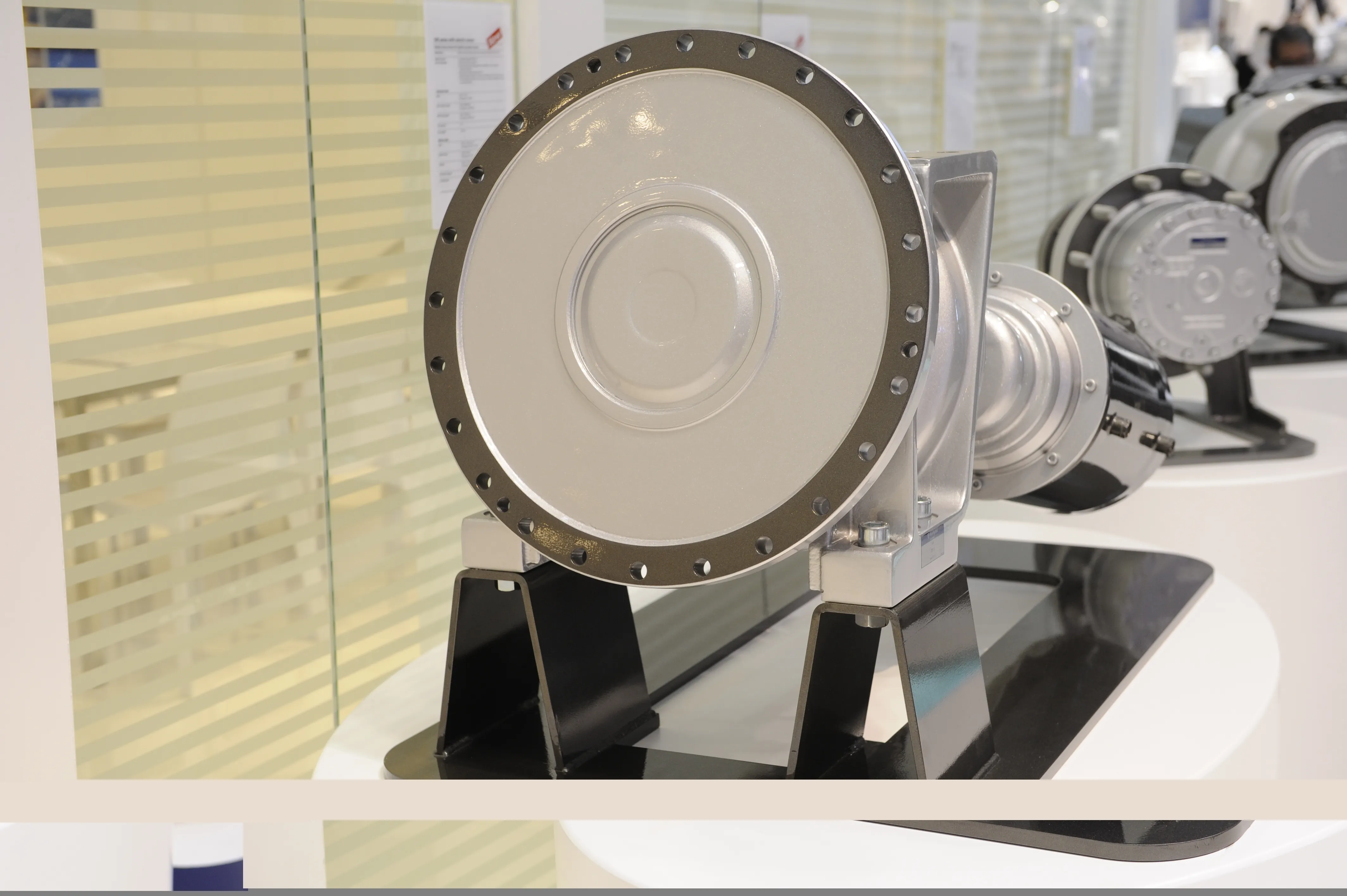

One trend being seen in hybrid and all-electric vehicles is for these to feature more than one drive motor. For example, in-wheel motors as on the best-selling pure electric bus the BYD B9 recently landing orders up to 2000 at a time. Many cars planned for imminent launch have in-wheel motors in two or four wheels. Using multiple motors may be used to offer four wheel drive, greater efficiency, release of space, modularisation and redundancy all achieved with inboard motors. The IDTechEx report, "Electric Motors for Electric Vehicles 2015-2025" www.idtechex.com/emotors analyses all this and give forecasts for the place of electric traction motors in the creation of the US$500 billion plus market for electric vehicles emerging in 2025.

There is a trend towards integrating the wheel motors with vehicle electronics, brakes and other systems. Mechanical, electric and electronic components are merging. And even conventional vehicles are becoming more electrical and electronic and less mechanical.

Several companies are printing electric cars and Harvard University has printed much of the electronics, a lithium battery and it plans to print a motor though all of these are small initially. Meanwhile,2728 Toyota hybrid transmissions include two motors, one acting as both generator and torque assist and the power electronics is embedded.

New technology allows for the batteries or super-capacitors to become structural components, saving weight and space. As the batteries become solid state the can become part of the internal and external bodywork, also allowing self-cooling and possibly managing higher performance. This is highlighted in another report from IDTechEx, "%$Linker:2 External <?xml version="1.0" encoding="utf-16"?><dictionary /> 0 0 0 oLinkExternal Structural Electronics 2015-2025 Visit structural page false http://www.idtechex.com/structural false false %>".

There is some discussion that traction motors could be driven by supercabatteries (hybrid supercapacitors sometimes in the form of Asynchronous Electrochemical Double Layer Capacitors AEDLC also called lithium-ion capacitors). These can offer the one million cycle life of the supercapacitor, exceptional power density, good series resistance and the energy density of the lithium-ion battery or at least a lead-acid battery. Use in hybrids is now commonplace for supercapacitors. Higher power densities may call for motors improved so they can withstand the newly available pulses of power thus delivering better performance.

One trend being seen in hybrid and all-electric vehicles is for these to feature more than one drive motor. For example, in-wheel motors as on the best-selling pure electric bus the BYD B9 recently landing orders up to 2000 at a time. Many cars planned for imminent launch have in-wheel motors in two or four wheels. Using multiple motors may be used to offer four wheel drive, greater efficiency, release of space, modularisation and redundancy all achieved with inboard motors. The IDTechEx report, "Electric Motors for Electric Vehicles 2015-2025" www.idtechex.com/emotors analyses all this and give forecasts for the place of electric traction motors in the creation of the US$500 billion plus market for electric vehicles emerging in 2025.

There is a trend towards integrating the wheel motors with vehicle electronics, brakes and other systems. Mechanical, electric and electronic components are merging. And even conventional vehicles are becoming more electrical and electronic and less mechanical.

Several companies are printing electric cars and Harvard University has printed much of the electronics, a lithium battery and it plans to print a motor though all of these are small initially. Meanwhile,

New technology allows for the batteries or super-capacitors to become structural components, saving weight and space. As the batteries become solid state the can become part of the internal and external bodywork, also allowing self-cooling and possibly managing higher performance. This is highlighted in another report from IDTechEx, "%$Linker:

There is some discussion that traction motors could be driven by supercabatteries (hybrid supercapacitors sometimes in the form of Asynchronous Electrochemical Double Layer Capacitors AEDLC also called lithium-ion capacitors). These can offer the one million cycle life of the supercapacitor, exceptional power density, good series resistance and the energy density of the lithium-ion battery or at least a lead-acid battery. Use in hybrids is now commonplace for supercapacitors. Higher power densities may call for motors improved so they can withstand the newly available pulses of power thus delivering better performance.