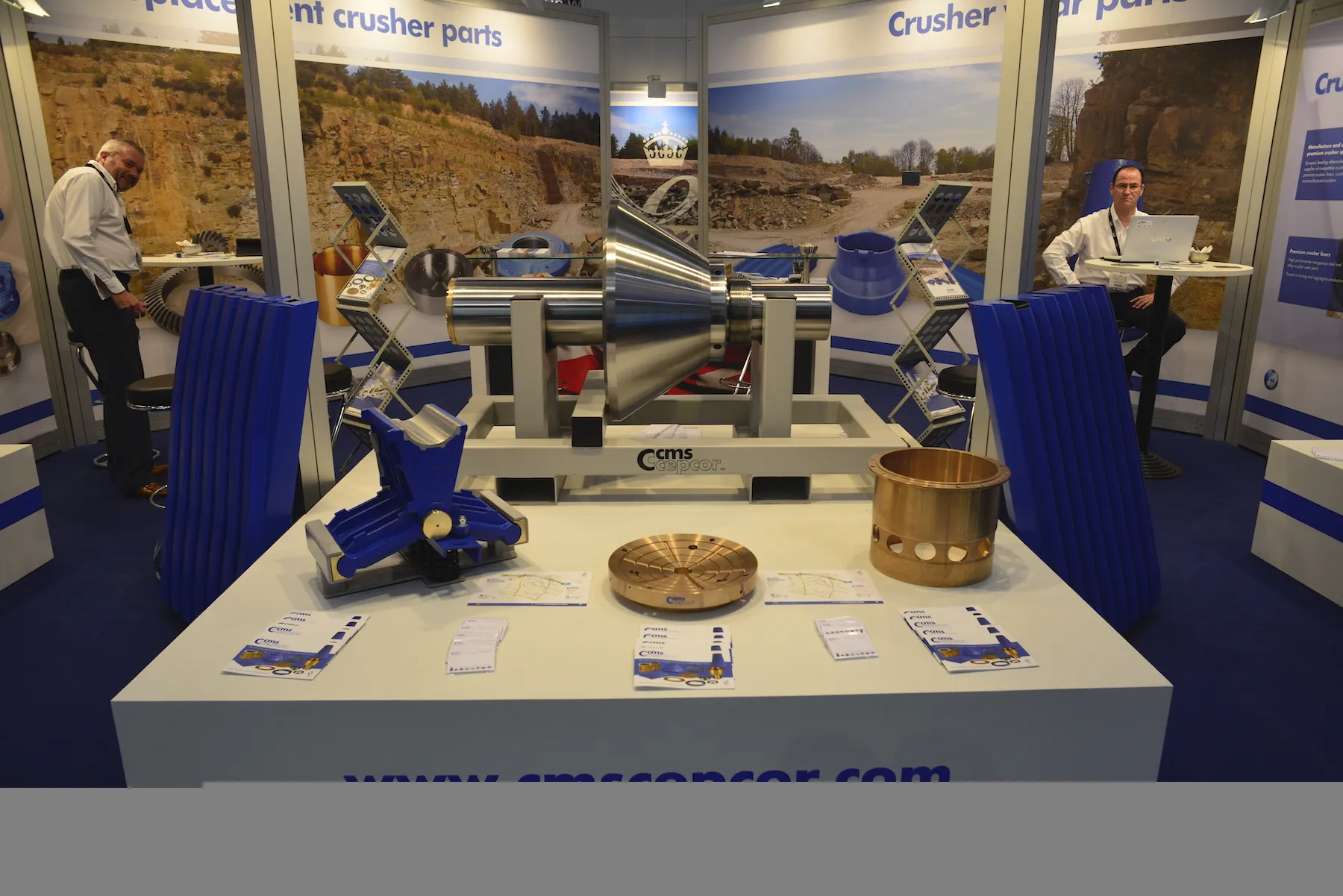

First-time exhibitor CMS Cepcor will exhibit its range of replacement crusher spare parts and premium crusher liners at bauma 2013. Recently awarded the Queen’s Award for Outstanding Achievement in International Trade, CMS Cepcor currently exports to over 100 countries. Despite the worldwide economic recession and credit crisis, the company says its sales turnover increased by over 100% since 2010. “This growth has been achieved through a focus on optimisation of web presence together with an engineering f

March 11, 2013

Read time: 2 mins

First-time exhibitor 6017 CMS Cepcor will exhibit its range of replacement crusher spare parts and premium crusher liners at 688 Bauma 2013.

Recently awarded the Queen’s Award for Outstanding Achievement in International Trade, CMS Cepcor currently exports to over 100 countries.

Despite the worldwide economic recession and credit crisis, the company says its sales turnover increased by over 100% since 2010.

“This growth has been achieved through a focus on optimisation of web presence together with an engineering focus on producing quality products, plus an expansion of the range of services offered to their ever increasing customer base,” says CMS Cepcor.

“More overseas visits for direct contact with customers and establishing business partners in key overseas territories have also aided their rapid growth.”

The company says that one element of its current success has been recent investment in its UK manufacturing facility, where the extensive facilities incorporate CNC machining capabilities; specialist tooling; coordinate measuring equipment and the latest CAD design capabilities, managed by a team with expertise in the design, manufacture, operation and maintenance of crushing and associated equipment.2 Internal <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 11560 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/bauma-2013/video/ true false %>

Recently awarded the Queen’s Award for Outstanding Achievement in International Trade, CMS Cepcor currently exports to over 100 countries.

Despite the worldwide economic recession and credit crisis, the company says its sales turnover increased by over 100% since 2010.

“This growth has been achieved through a focus on optimisation of web presence together with an engineering focus on producing quality products, plus an expansion of the range of services offered to their ever increasing customer base,” says CMS Cepcor.

“More overseas visits for direct contact with customers and establishing business partners in key overseas territories have also aided their rapid growth.”

The company says that one element of its current success has been recent investment in its UK manufacturing facility, where the extensive facilities incorporate CNC machining capabilities; specialist tooling; coordinate measuring equipment and the latest CAD design capabilities, managed by a team with expertise in the design, manufacture, operation and maintenance of crushing and associated equipment.

Stand: B2.324

%$Linker:

%$Linker: