Magni Telescopic Handlers has ambitious plans to increase its share of the telehandler market after its €15-20million investment in machines, attachments and a new production facility. At bauma 2013, Magni has unveiled its RTH and HTH models. The RTH range consists of seven rotating telehandler models, and the HTH range of two heavy-duty machines for the mining and oil industry, with a further model in development.

January 6, 2017

Read time: 2 mins

At bauma 2013, Magni has unveiled its RTH and HTH models. The RTH range consists of seven rotating telehandler models, and the HTH range of two heavy-duty machines for the mining and oil industry, with a further model in development.

The RTH range spans from four to six tonnes maximum loading capacity and from 17.5m-29.9m maximum lifting height. The HTH range will eventually span 15-30tonnes maximum loading capacity. The small 15tonne machine is still being developed.

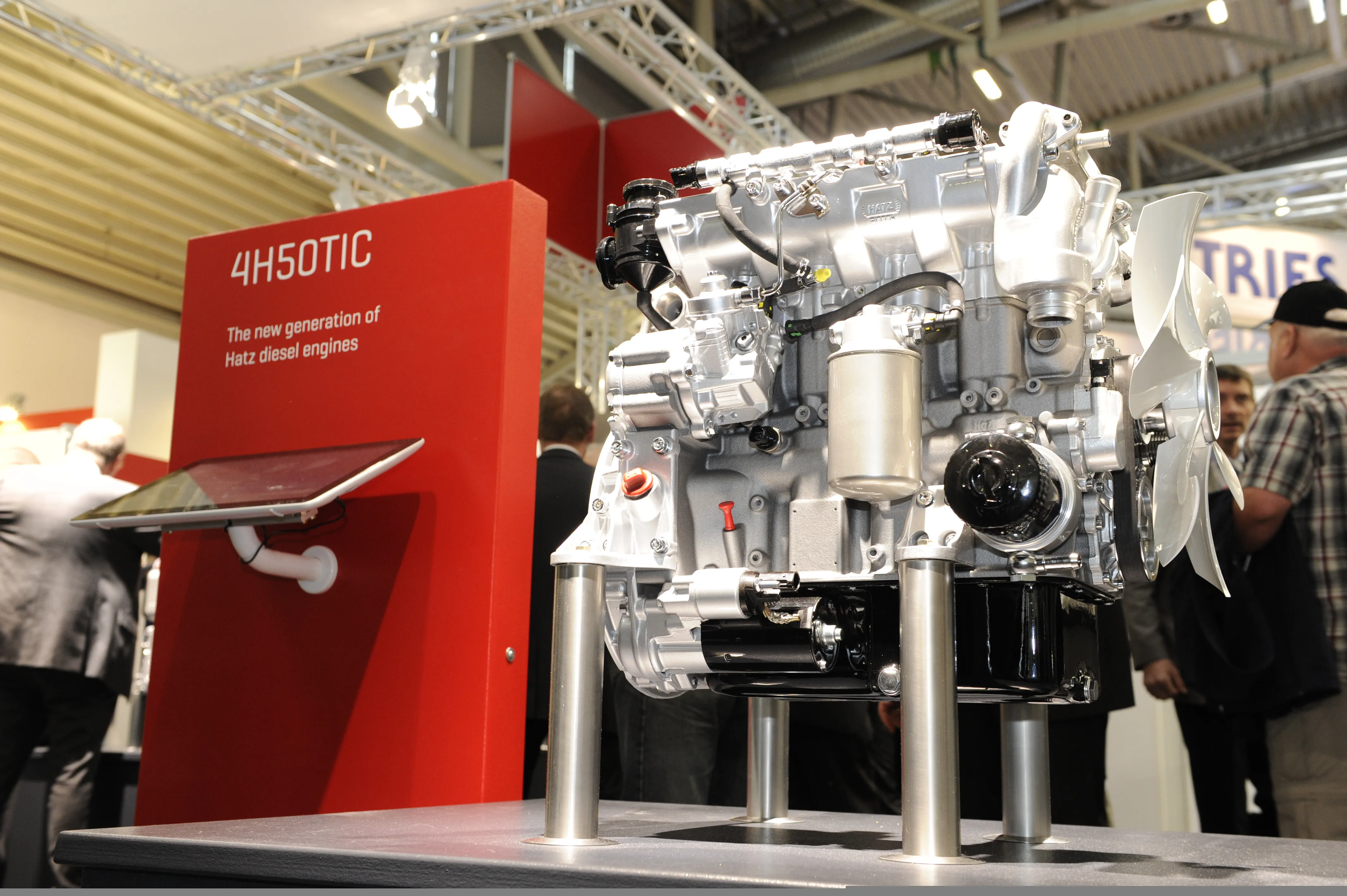

Earlier this year, Magni signed a major supply agreement with JCB to equip its RTH range with the new

Of the firm’s new 6,000m² production facility near Modena, Italy, Magni president Riccardo Magni said, “We are making a machine a day. We are looking to have 200 machines manufactured this year. There is no problem with capacity, and we have a very short delivery time of 60 days.”

Around 50% of this year’s machine manufacturing output will be sold through the JCB dealership network, said Magni. View more stories