The company, whose extensive global customer product range includes surface drill rigs and breakers for quarries, received orders worth SEK 36.579bn (€3.612bn) in 2020 (-7% on SEK 39.492bn (€3.9bn) in 2019). Epiroc posted 2020 revenues of SEK 36.122bn (€3.567bn) (-12% on SEK 40.849bn (€4.034bn) in 2019); and an annual operating profit of SEK 7.382bn (€729.04mn) (-9% on SEK 8.136bn (€803.5mn) in 2019).

Commenting in Epiroc’s Annual & Sustainability Report 2020, Hedblom said: “Customer demand recovered in the second half of the year, as the level of restrictions eased off and more mining and infrastructure sites were operational.

“It is clear that the pandemic – or rather the restrictions that forced customers to either stop or reduce activities – have increased the interest in our automation and digital solutions. Our customers have shown a growing interest in these solutions for several years, and this trend has accelerated. This is the case not only in the developed markets that have been early adopters in the past but in all markets. Our decision to establish regional application centres around the world have contributed to making this happen. By bringing innovations and solutions closer to the customers, we make it easier for them to embrace new technologies.”

Hedblom said that Epiroc’s “agile” business model has allowed the company to “continuously adapt to the market situation”. She continued: “On June 18, we celebrated our two-year anniversary as a listed company. The celebration was, of course, held online due to the pandemic. We have the speed and agility of a young and hungry company but with significant experience and deep roots dating back to 1873. As we build for the future, we remain focused on our strategic priorities: innovation, aftermarket, operational excellence and sustainability.

“Coming from the R&D area myself, innovation is close to my heart. Innovation is in our DNA, and we are investing more than we have ever done in R&D to stay ahead. In addition, our relentless focus on innovation extends beyond what we do ourselves. We also leverage the R&D from customers, suppliers and other partners. Examples of powerful partnerships: with Mobilaris, we innovate on positioning systems underground; with ASI Mining and Combitech, we develop solutions for autonomous operations and information management; with Orica, we develop solutions for semi-automated explosives charging; with Northvolt and ABB, we collaborate on battery-electric vehicles, batteries and electric drive trains; and with Ericsson, we work on 5G connectivity.”

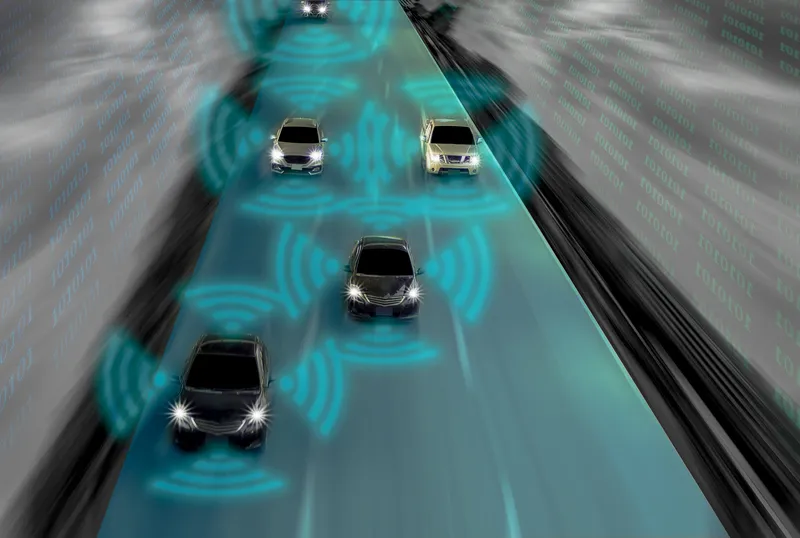

Hedblom believes three major technology shifts are making the mining and infrastructure industries more productive and sustainable: automation, digitalisation, and electrification. She said that Epiroc is in the “driver’s seat” for these shifts, which benefit the company’s customers in many ways. Hedblom says Epiroc will continue to enter strategic partnerships and foster an innovative culture to remain at the forefront of this evolving industrial landscape.

She added: “We have a market-leading position in automation with proven solutions throughout the world. For example, in 2020, we began implementing the world’s largest mixed–fleet automation project for Roy Hill’s iron ore surface mining operation in Australia together with ASI Mining. We also made progress on the world’s largest mixed-fleet automation initiative for underground mining, for Newcrest Mining in Australia. Automation is key for several reasons. First of all, it is about protecting people, keeping them away from dangerous situations. The customers also benefit from increased productivity, lower fuel consumption and reduced total cost of ownership.”

Hedblom said digitalisation offers much potential both for Epiroc’s customers and the company. “We offer a wide range of digital solutions. For example, connectivity to locate machines and people in a mine, teleremote steering of equipment, and fully autonomous solutions. Digitalisation also improves our operations. Our increased adoption and use of Robotic Process Automation make our processes more efficient and reduce the need for mundane data entry.”

Hedblom stressed that the more machine data Epiroc gained, the better the company can develop its equipment. “It also makes us more efficient in how we work with the aftermarket. The more information, the better value proposition we can offer our customers, strengthening their productivity and safety. In sum, connectivity is positive in many ways.”

Emphasising Epiroc’s long history of electrification, Hedblom said: “Already in the 1970s, we offered electric powered drill rigs using cables. Today, we offer the largest range of battery-electric vehicles for underground applications, with customers on every continent. In 2020, we worked hard to extend the offering further and to help customers take the step into electric. Our batteries as a service concept lower the bar to entry, as the customer does not have to make the capital investment. Instead, the customer pays an ongoing fee when using the service. We will offer all our equipment in battery-electric versions by 2025 for underground and by 2030 for surface. The technology is now well established, and more and more customers are realising the advantages that come with using electric machines instead of diesel. The benefits include improved health and safety due to less emissions in use, noise and heat, and the lower total cost of operation and higher productivity.”

Hedblom said Epiroc will always look to acquire businesses that can enhance the company’s technology leadership, presence in the market and/or its offer to the market.

“In 2020, we announced a couple of acquisitions. In December, for example, we announced the acquisition of MineRP with around 200 employees. The company, which has offices in South Africa, Canada, Australia, and Chile, supports large and medium-sized mines in optimising their efficiency by providing a leading software platform solution that integrates technical mining data. The combination of MineRP’s platform with Epiroc’s digital solutions, partners, and global presence has the potential to transform the way that mines operate.”

Looking at Epiroc’s trading priorities for the current year, Hedblom said: “For 2021, we have many exciting products and solutions coming to the market. To mention just a couple: The new generation Boomer designed for mining contractors will launch at the beginning of the year. It is a true development rig, fully equipped for multi-task operation and automation. Of course, we will also provide a battery-electric driveline option in due course.

“Another revolutionary innovation is our coming offering of fully mechanised charging through our collaboration with Orica, the leading explosives manufacturer, to improve the safety and work environment for operators. In 2021, the field testing of the prototype starts.”

Commenting on where she sees Epiroc in ten years, Hedblom said: “We know that our customers have many challenges. Epiroc will be ‘the enabler’ in providing solutions to overcome these challenges and lead the transition towards sustainable mining and infrastructure. To offer best-in-class solutions – with automation, digitalisation, and electrification – and always being close to our customers, we will further strengthen the relationships with our customers and make Epiroc even stronger. We dare to think new.”