Sandvik Mining and Construction has launched a new breaker and mobile crushing plant at INTERMAT. The stand also emphasizes the company’s commitment to manufacturing and supporting both products and customers in an environmentally sustainable manner. The BR1533 hydraulic breaker weighs 870kg and is suitable for carriers in the 10 to 20tonne range. With an impact rate of 550 to 1050 blows per minute, the BR1533 features Sandvik’s Fixed Blow Energy system that ensures optimum impact energy with every blow, re

January 6, 2017

Read time: 2 mins

The stand also emphasizes the company’s commitment to manufacturing and supporting both products and customers in an environmentally sustainable manner.

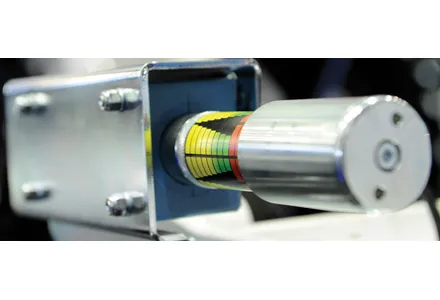

The BR1533 hydraulic breaker weighs 870kg and is suitable for carriers in the 10 to 20tonne range. With an impact rate of 550 to 1050 blows per minute, the BR1533 features Sandvik’s Fixed Blow Energy system that ensures optimum impact energy with every blow, regardless of hydraulic flow fluctuations.

“The BR1533 benefits from a radical lightweight design providing the unit with a class-leading power-to-weight ratio that enables customers to enjoy high levels of productivity in a wide variety of demolition, recycling, quarrying and other associated applications,” said Satu Ramo, Sandvik marketing communications manager, construction.

The QI240 demolition and recycling impact crusher is purpose-designed to process construction materials on site and has been designed with mobility, productivity and transportability in mind. It reflects Sandvik’s commitment to servicing the growing market for the recycling of construction materials and the production of high quality aggregates from materials previously seen as waste.

%$Linker: