Sweden’s engcon, one of the world's leading tiltrotator manufacturers, is now increasing its efforts in the North American construction market.

January 6, 2017

Read time: 2 mins

Sweden’s 705 Engcon, one of the world's leading tiltrotator manufacturers, is now increasing its efforts in the North American construction market.

“We are primarily looking for more dealers to get in closer contact with the customers (and) the North American market has huge potential,” says Stig Engström, owner and founder of Engcon, speaking at Conexpo 2014.

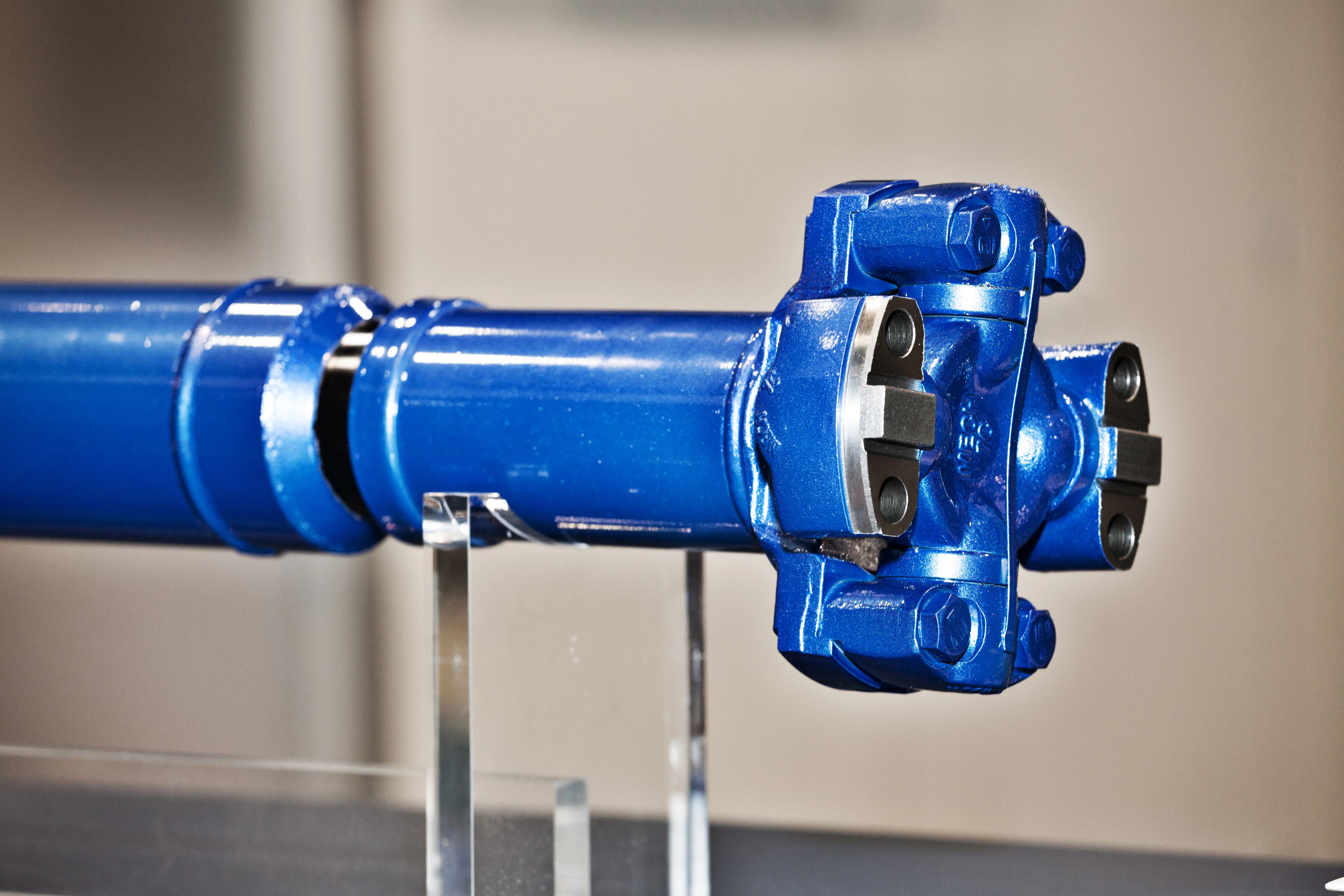

Based in Strömsund in northern Sweden, Engström has invested all of his time and money into developing the tiltrotator, a type of wrist that can be mounted on the excavator shaft allowing it to both rotate and tilt.

Today, and several entrepreneurial prizes later, Engström says Engcon's tilt rotator is integral to many of the excavators used in the Scandinavian market, and sales are growing rapidly in the rest of Europe. Engcon's goal now is to firmly establish its brand in North America.

“We already have dealers in the US, but I consider this year's Conexpo as the starting point of an intensified focus,” he adds. “We need to show the benefits and the profitable advantages of the tiltrotator to both possible dealers and end customers.”

Engcon has produced a full range of tools and attachments that further increase the excavator's flexibility and profitability.

The company is headquartered in Sweden with dealerships and sales offices in Finland, Denmark, Germany, France, the UK, Poland and Australia. The firm also has dealers in Canada, USA, Austria, Belgium, the Czech Republic, Holland, Iceland, Italy, Russia, Slovenia, Spain and Switzerland.%$Linker:2 Asset <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 42633 0 oLinkExternal www.engcon.se  Visit Engcon Website false /EasySiteWeb/GatewayLink.aspx?alId=42633 false false %>

“We are primarily looking for more dealers to get in closer contact with the customers (and) the North American market has huge potential,” says Stig Engström, owner and founder of Engcon, speaking at Conexpo 2014.

Based in Strömsund in northern Sweden, Engström has invested all of his time and money into developing the tiltrotator, a type of wrist that can be mounted on the excavator shaft allowing it to both rotate and tilt.

Today, and several entrepreneurial prizes later, Engström says Engcon's tilt rotator is integral to many of the excavators used in the Scandinavian market, and sales are growing rapidly in the rest of Europe. Engcon's goal now is to firmly establish its brand in North America.

“We already have dealers in the US, but I consider this year's Conexpo as the starting point of an intensified focus,” he adds. “We need to show the benefits and the profitable advantages of the tiltrotator to both possible dealers and end customers.”

Engcon has produced a full range of tools and attachments that further increase the excavator's flexibility and profitability.

The company is headquartered in Sweden with dealerships and sales offices in Finland, Denmark, Germany, France, the UK, Poland and Australia. The firm also has dealers in Canada, USA, Austria, Belgium, the Czech Republic, Holland, Iceland, Italy, Russia, Slovenia, Spain and Switzerland.%$Linker: