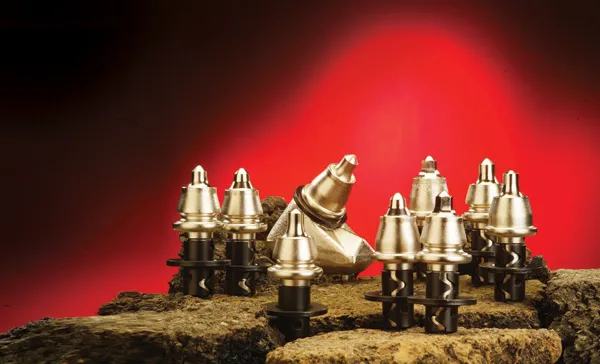

Element Six says that its D Power road pick has 40 times the life of a standard pick and gives smoother surfaces. The tip is made of what the company says is the hardest material on the planet – polycrystalline diamond. Milling time is reduced as fewer stoppages are needed for pick changes, according to Element Six.

January 6, 2017

Read time: 2 mins

RSS704 Element Six says that its D Power road pick has 40 times the life of a standard pick and gives smoother surfaces.

The tip is made of what the company says is the hardest material on the planet - polycrystalline diamond – and that the design combines toughness with extremely high wear resistance. Milling time is reduced as fewer stoppages are needed for pick changes, according to Element Six.

The D Power road pick is aimed at for road resurfacing and repair. Element Six said results of its European testing programme showed that the D Power road pick exceeds the life of an industry standard pick by 40 times.

Kalle Hildebrand, executive director, hard materials at Element Six, said that customers using the new D Power road pick in trials have been telling the company that the new pick gives a competitive advantage. “They see this pick as a way for them to stay one step ahead of the competition, thanks to the contribution these picks can make in reducing their project costs and improving project completion times,” he said.

Advantages of this extension in pick life include lower lifetime costs, improved milling machine productivity, reduced downtime for pick changes, greater fuel efficiency and a better delivered surface finish, according to Element Six.

View more stories

View more videos

The tip is made of what the company says is the hardest material on the planet - polycrystalline diamond – and that the design combines toughness with extremely high wear resistance. Milling time is reduced as fewer stoppages are needed for pick changes, according to Element Six.

The D Power road pick is aimed at for road resurfacing and repair. Element Six said results of its European testing programme showed that the D Power road pick exceeds the life of an industry standard pick by 40 times.

Kalle Hildebrand, executive director, hard materials at Element Six, said that customers using the new D Power road pick in trials have been telling the company that the new pick gives a competitive advantage. “They see this pick as a way for them to stay one step ahead of the competition, thanks to the contribution these picks can make in reducing their project costs and improving project completion times,” he said.

Advantages of this extension in pick life include lower lifetime costs, improved milling machine productivity, reduced downtime for pick changes, greater fuel efficiency and a better delivered surface finish, according to Element Six.

Hall: 3 Stand C012

RSSView more stories

View more videos