Using Ammann’s AS1 plant control system, the EcoMix concrete plant combines accurate measuring equipment and comprehensive process control to guarantee perfect, repeatable results, claimed Ammann. The galvanised steel support structure is light, warp resistant and also suitable for areas of increased seismic activity, it is claimed. The EcoModule is equipped with the company’s tried and tested Amix twinshaft paddle mixer and is pre-assembled and tested at the factory.

January 6, 2017

Read time: 1 min

Using 3764 Ammann Group’s AS1 plant control system, the EcoMix concrete plant combines accurate measuring equipment and comprehensive process control to guarantee perfect, repeatable results, claimed Ammann.

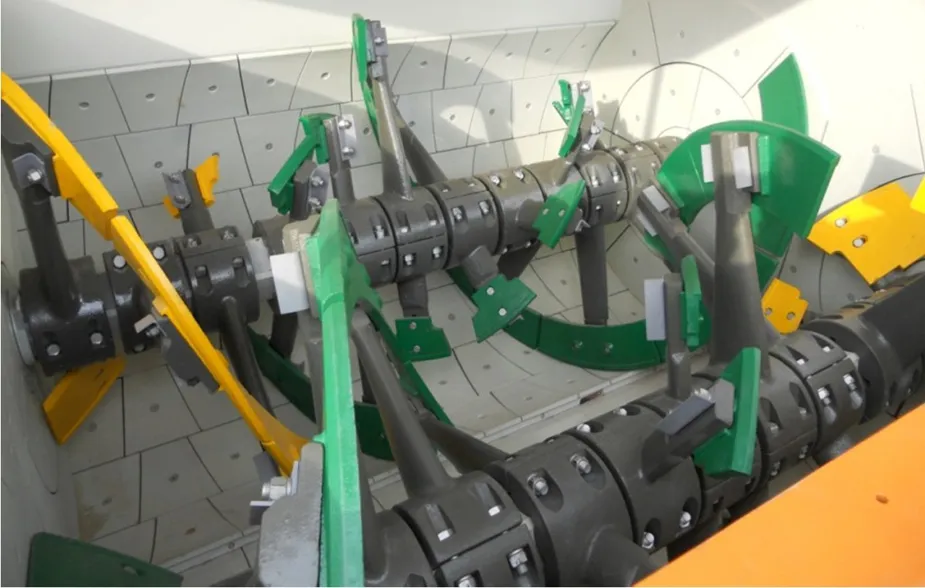

The galvanised steel support structure is light, warp resistant and also suitable for areas of increased seismic activity, it is claimed. The EcoModule is equipped with the company’s tried and tested Amix twinshaft paddle mixer and is pre-assembled and tested at the factory.

Combined with cement silos of up to 800tonnes capacity and aggregate silos up to 750m3, output of the EcoMix plant is up to 190m3 of hardened concrete/hour.

Optional heating or cooling equipment is energy-efficient and makes the plant suitable for any climate zone. With low dust and noise emissions, Ammann reckoned The EcoMix is also suitable for urban areas.

2 Internal 2 4824 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/intermat-2012/video/ true false %>

The galvanised steel support structure is light, warp resistant and also suitable for areas of increased seismic activity, it is claimed. The EcoModule is equipped with the company’s tried and tested Amix twinshaft paddle mixer and is pre-assembled and tested at the factory.

Combined with cement silos of up to 800tonnes capacity and aggregate silos up to 750m3, output of the EcoMix plant is up to 190m3 of hardened concrete/hour.

Optional heating or cooling equipment is energy-efficient and makes the plant suitable for any climate zone. With low dust and noise emissions, Ammann reckoned The EcoMix is also suitable for urban areas.

%$Linker:

Hall: 5B Stand: F028

%$Linker: