A new generation of dynamic testing systems for road paving materials, Dynapave, will be unveiled by Italian testing equipment manufacturer Controls.

January 6, 2017

Read time: 2 mins

%$Linker: 2 Internal 2 4802 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">RSS</span></span> Road Paving and Recycling false /event-news/intermat-2012/rss/road-paving-and-recycling/ true false %>A new generation of dynamic testing systems for road paving materials, Dynapave, will be unveiled by Italian testing equipment manufacturer 2139 Controls.

The company says that the empirical testing of asphalt adapted until now is “no longer sufficient to support the leap in quality of paving over time due to the continual increase of road traffic in terms of frequency, weight, and load time.”

Its research and development department acknowledged the new requirements as long ago as 1987.

“A vast range of testing apparatus for asphalt and bituminous mixtures has been considerably increased with the adoption of the [US] Superpave testing methods and subsequent ASTM, AASHTO, EN Standards and a key role is played by the dynamic technologies,” says Controls.

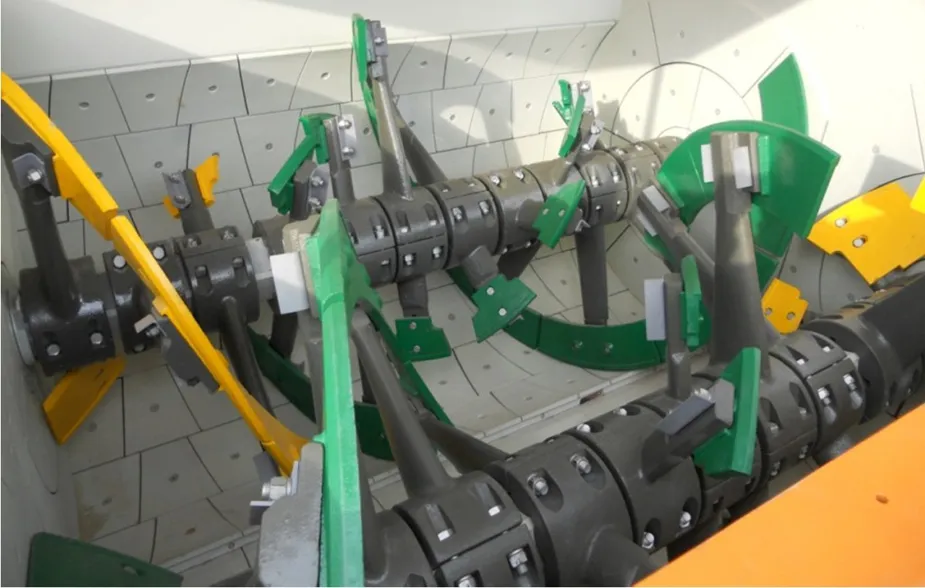

New at Intermat is the Dynapave 78-B7030, servo-pneumatic dynamic testing system with a 30kN capacity to perform indirect tensile stiffness, creep, fatigue, triaxial on unbound materials and tests under load or displacement control. It joins the company’s PILOT 4 automatic compression tester for concrete; Gyrocomp gyratory compactor for bituminous mixes and the 48-D5262 accelerated polishing machine for polished stone value.

According to Controls, the Dynapave system performs load or displacement controlled tests with programmable wave shape over frequencies up to 70Hz, simulating the traffic effect.

“The user-friendly interface allows the operator to monitor the test performance and to evaluate results,” says the company.

2 Internal 2 4824 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/intermat-2012/video/ true false %>

The company says that the empirical testing of asphalt adapted until now is “no longer sufficient to support the leap in quality of paving over time due to the continual increase of road traffic in terms of frequency, weight, and load time.”

Its research and development department acknowledged the new requirements as long ago as 1987.

“A vast range of testing apparatus for asphalt and bituminous mixtures has been considerably increased with the adoption of the [US] Superpave testing methods and subsequent ASTM, AASHTO, EN Standards and a key role is played by the dynamic technologies,” says Controls.

New at Intermat is the Dynapave 78-B7030, servo-pneumatic dynamic testing system with a 30kN capacity to perform indirect tensile stiffness, creep, fatigue, triaxial on unbound materials and tests under load or displacement control. It joins the company’s PILOT 4 automatic compression tester for concrete; Gyrocomp gyratory compactor for bituminous mixes and the 48-D5262 accelerated polishing machine for polished stone value.

According to Controls, the Dynapave system performs load or displacement controlled tests with programmable wave shape over frequencies up to 70Hz, simulating the traffic effect.

“The user-friendly interface allows the operator to monitor the test performance and to evaluate results,” says the company.

%$Linker: